Hello I'm working the install of my Pacific Energy LE Insert. I'm looking for help on where to place my temperature sensor, and what type. If I use a probe, it will be located only 5 to 8 inches above the unit (just above the damper, path notated). Not much room above this unit with the block off plate.

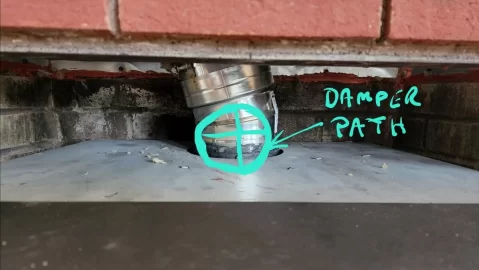

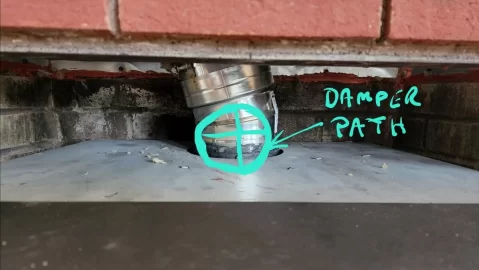

I'm working the install of my Pacific Energy LE Insert. I'm looking for help on where to place my temperature sensor, and what type. If I use a probe, it will be located only 5 to 8 inches above the unit (just above the damper, path notated). Not much room above this unit with the block off plate.

I'm wondering if i should use a probe or just face measurement with an Auber Instruments unit either way. Opinions on this welcomed.

I am installing a Dywer Magnehelic as well, and that will have to be above the damper. I'm hoping static pressure above the damper will be very close to below the damper. Can't remember if i did this experiment in the late winter, believe I did. This is a static pressure measurement, perpendicular to try he airflow, to remove the pressure effects of gas velocity.

Hoping I can keep the new unit in the specification limits, <= 0.12 for draft, with the pressure gauge, damper, and temperature gauge.

Thoughts? Opinions?

Thanks.

I'm working the install of my Pacific Energy LE Insert. I'm looking for help on where to place my temperature sensor, and what type. If I use a probe, it will be located only 5 to 8 inches above the unit (just above the damper, path notated). Not much room above this unit with the block off plate.

I'm working the install of my Pacific Energy LE Insert. I'm looking for help on where to place my temperature sensor, and what type. If I use a probe, it will be located only 5 to 8 inches above the unit (just above the damper, path notated). Not much room above this unit with the block off plate. I'm wondering if i should use a probe or just face measurement with an Auber Instruments unit either way. Opinions on this welcomed.

I am installing a Dywer Magnehelic as well, and that will have to be above the damper. I'm hoping static pressure above the damper will be very close to below the damper. Can't remember if i did this experiment in the late winter, believe I did. This is a static pressure measurement, perpendicular to try he airflow, to remove the pressure effects of gas velocity.

Hoping I can keep the new unit in the specification limits, <= 0.12 for draft, with the pressure gauge, damper, and temperature gauge.

Thoughts? Opinions?

Thanks.