Viggyowner said:

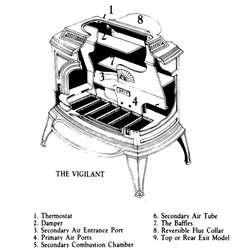

As has been said before that little hole in the left side feeds those 5 little holes in the lower rear fireback only. The hole at the rear controlled by the thermostatic flapper valve feeds air to that large curved tube in the lower left of the firebox.

Actually, all of the draft openings inside the stove are for primary combustion. The five small holes along the bottom of the fireback are the principal mode of air introduction into the fire zone. The entire left side could be blocked with ashes (been there) and the stove would probably run OK, just as long as those five holes in the back are clean and open.

The small hole in the left side of the stove is what feeds the secondary combustion. Air is introduced through a channel behind the fireback (where you can't see it). Under normal conditions, this should be open all the way, but you can experiment with partial opening to see if your burn improves. Bottom line is that this stove is a pretty old design, and it has no insulation surrounding the secondary burn chamber to keep the combustion temps up. You need to get the stove really hot back there for sustained secondary combustion to occur.

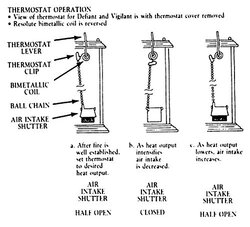

At very high temps, the thermostat in the back will close the primary air intake (flapper door) almost all the way if the thermostat chain is correctly adjusted (45º angle of the flapper when stove is ice cold). Don't forget, there is a handle on the thermostat for a reason. Pulling the lever to the left (as you face the stove from the front) will allow more air to come into the primary burn zone at all stove temps. This will allow more air to come in at higher burn rates, but will let too much air in as the stove cools down.

Moving the lever to the right allows less air to come into the primary zone at all temps. Getting the stove real hot (650-750º) and then shutting the primary down too far may starve the primary fire of the necessary air. Don't count on the secondary burn to clean things up like it would in a modern stove. Chances are that you will get a smoldering burn in the firebox and not enough heat to keep temps high enough in the secondary chamber for smoke reburn to occur.

With my flue and burn practices, I liked to set my thermostat so that the flapper was open about a 1/8" to 1/4" when the stove was fully involved. On my stove, that was usually with the lever tilted just to the left of vertical. Always had long overnight burns that way, with plenty of coals and a warm stove 8 hours after a full load.

BTW if your flapper door is not opening back up as the stove cools, there is probably something binding at the hinge joint that is preventing it from pivoting on the hinge pin, or your bi-metalic coil is shot. Check for free movement up and down while the stove is cold. You should feel fair resistance to closing the flapper manually if the coil still has plenty of spring left in it. Attached below are a cutaway drawing of the stove and a drawing of the correct position for the thermostat linkage.