Had an Ecosy+ Hampton 5 SE installed on Wed 16th September, T shape slate hearth,. We had a few evening lights but Fri 24th we were off work, sitting in and had the stove running from about 4 or 5 pm for a proper run to get the heat in the room. Once everything was up to temperature for a while and we approach to place another log within, we notice a crack running from the front left foot area. Small semi-circle. We advise installer the next day.

We continued to use anyway in the next few days and the crack crept forward to the central area and then over to the area where the cut out corner of the slate. The rear of the hearth where the stove sat was lifted and I would say hearth warped. When it cooled down the next day the crack had levelled off and you could barely catch a nail on it.

2ND HEARTH INSTALLED on Afternoon of Thursday 1st October, lit on Saturday and low and behold a crack has appeared on the right hand in a similar fashion, again raising up at the rear section under the stove. Morning of Sunday 4th October you can't feel the crack, but can see it. Going to get it properly up to temperature again to see what happens. We put our coffee table and a clothes horse in the way and went into the kitchen for the evening to recover some chairs with the kids so I'm 110%confident no one jumped on it or was anywhere near it.

SO WHERE DO I GO FROM HERE? We purchased the stove from stoveworldUK and had it posted over to N.I. . A local company install everything from there. Building Control signed off and certified on 28th September. Ecosystoves manufacture and provided the manual for the stove recommending minimum 12mm hearth.

The installer offered a range of other stoves but this was one that we preferred just by doing research, however the installation method would have been the same. Our conversations after the first incident were that it was unheard of to the installer and hearth supplier. We discussed the various ways in which it would crack, which included standing on the edge and kids jumping on it which we asserted wasn't the case. We also had a slight gap left to run the carpet underneath the edge hence reason for suggesting we stood on it, however I demonstrated by standing on it and stated that if set properly it won't crack and there was no noise to suggest movement when I done so. Skirting stopped expansion and caused however I explained it wasn't nailed and only a slight bead of glue. finally as natural product it could have been a defect and stressed with heat.

I feel it is something to do with the way the heat is being dispersed into the slab and expansion because of the rear being higher when cracked and warm. The second time the bed for the hearth was taken to pretty much the edge of the hearth, with a slight gap for carpet and all feels fairly solid when I knock with a knuckle, much more solid than the 1st time.

We came to a mutual and amicable agreement: the hearth supplier supplied another at cost, and the installer split the cost between us. Extra £50 for us. At the time of the second install I questioned the possibility of it cracking again and pitched he idea of a 2 section hearth but the consensus was that it was that rare, it shouldn't happen again and we went with the 1 section.

So is it an issue with the manufacturer not testing or miss-calculating the parameters of hearths property or the Install? The hearth does seem to get quite warm.

Model, manual and photos below, any thoughts appreciated.

STOVE AND MANUAL: Ecosy+ Hampton 5 SE https://ecosystoves.co.uk/Hampton-5-Manual.pdf

https://ecosystoves.co.uk/hampton-wood-burning-stoves.html

Old fireplace ripped out:

Stove installed 1st occasion:

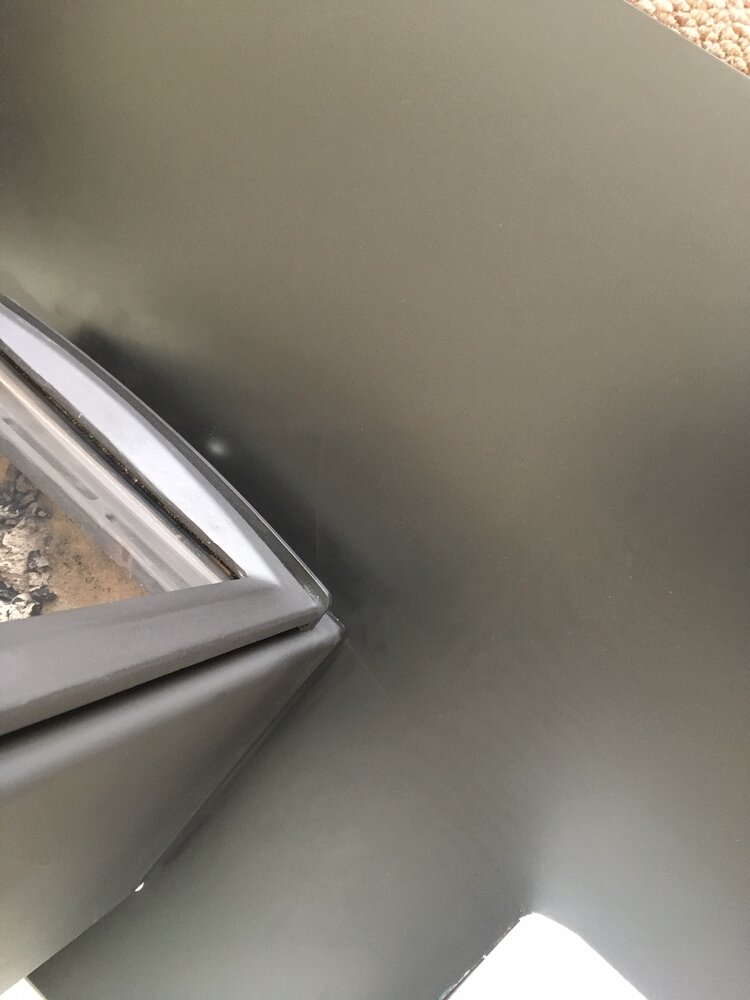

Crack from left foot:

Photo of 1st bed as the supplier was changing hearth

1st Bed stripped out before being relaid:

Hearth crack on second hearth:

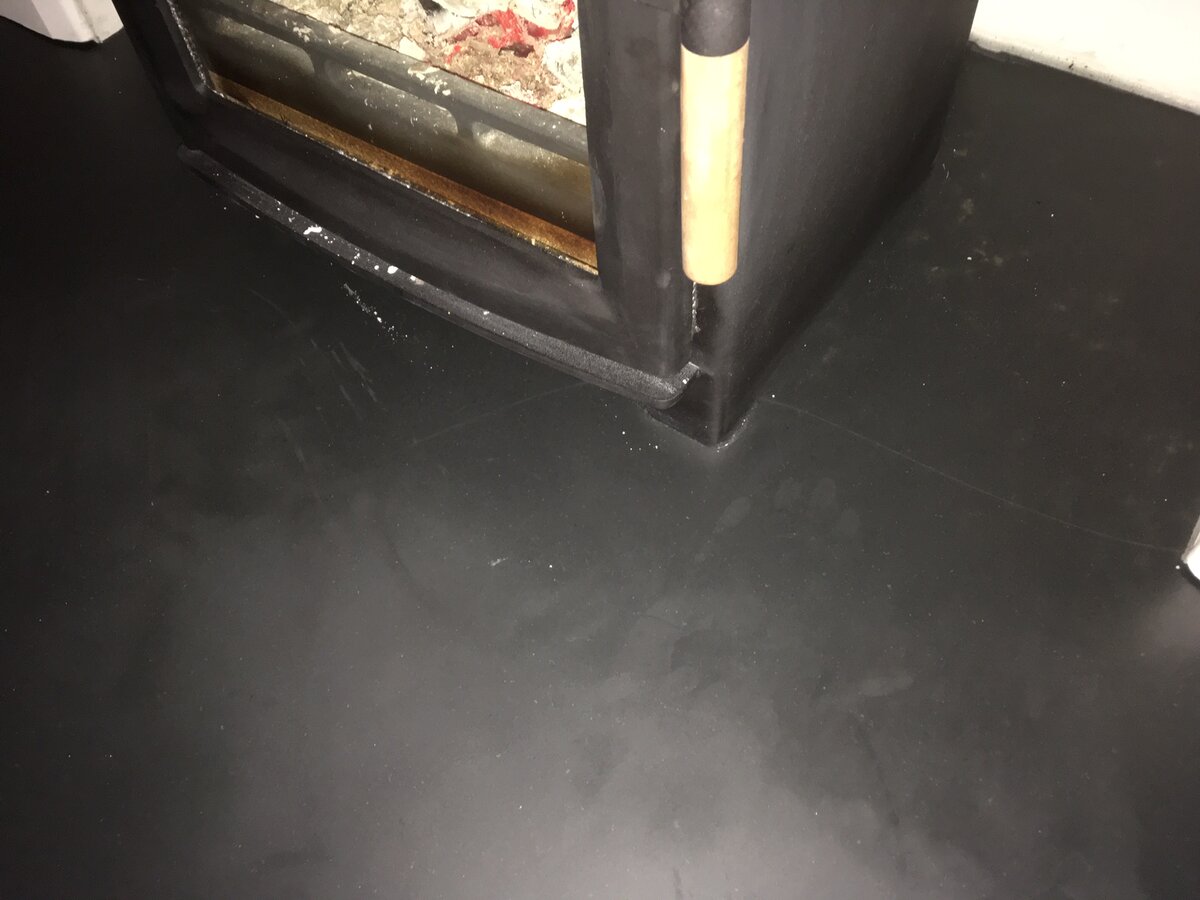

Expansion gap:

We continued to use anyway in the next few days and the crack crept forward to the central area and then over to the area where the cut out corner of the slate. The rear of the hearth where the stove sat was lifted and I would say hearth warped. When it cooled down the next day the crack had levelled off and you could barely catch a nail on it.

2ND HEARTH INSTALLED on Afternoon of Thursday 1st October, lit on Saturday and low and behold a crack has appeared on the right hand in a similar fashion, again raising up at the rear section under the stove. Morning of Sunday 4th October you can't feel the crack, but can see it. Going to get it properly up to temperature again to see what happens. We put our coffee table and a clothes horse in the way and went into the kitchen for the evening to recover some chairs with the kids so I'm 110%confident no one jumped on it or was anywhere near it.

SO WHERE DO I GO FROM HERE? We purchased the stove from stoveworldUK and had it posted over to N.I. . A local company install everything from there. Building Control signed off and certified on 28th September. Ecosystoves manufacture and provided the manual for the stove recommending minimum 12mm hearth.

The installer offered a range of other stoves but this was one that we preferred just by doing research, however the installation method would have been the same. Our conversations after the first incident were that it was unheard of to the installer and hearth supplier. We discussed the various ways in which it would crack, which included standing on the edge and kids jumping on it which we asserted wasn't the case. We also had a slight gap left to run the carpet underneath the edge hence reason for suggesting we stood on it, however I demonstrated by standing on it and stated that if set properly it won't crack and there was no noise to suggest movement when I done so. Skirting stopped expansion and caused however I explained it wasn't nailed and only a slight bead of glue. finally as natural product it could have been a defect and stressed with heat.

I feel it is something to do with the way the heat is being dispersed into the slab and expansion because of the rear being higher when cracked and warm. The second time the bed for the hearth was taken to pretty much the edge of the hearth, with a slight gap for carpet and all feels fairly solid when I knock with a knuckle, much more solid than the 1st time.

We came to a mutual and amicable agreement: the hearth supplier supplied another at cost, and the installer split the cost between us. Extra £50 for us. At the time of the second install I questioned the possibility of it cracking again and pitched he idea of a 2 section hearth but the consensus was that it was that rare, it shouldn't happen again and we went with the 1 section.

So is it an issue with the manufacturer not testing or miss-calculating the parameters of hearths property or the Install? The hearth does seem to get quite warm.

Model, manual and photos below, any thoughts appreciated.

STOVE AND MANUAL: Ecosy+ Hampton 5 SE https://ecosystoves.co.uk/Hampton-5-Manual.pdf

https://ecosystoves.co.uk/hampton-wood-burning-stoves.html

Old fireplace ripped out:

Stove installed 1st occasion:

Crack from left foot:

Photo of 1st bed as the supplier was changing hearth

1st Bed stripped out before being relaid:

Hearth crack on second hearth:

Expansion gap: