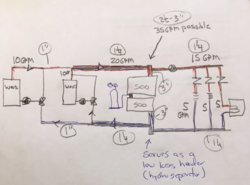

I have a Tarm Solo Plus that I've had for a few years now. I have 500 gallons of pressurized storage and my house has circulator pumps for each zone. I have 5 zones one of which is my hot water tank. My problem is that when one zone kicks on all the zones get hot.

I'm sure this isn't enough info to be useful. I have a circulator on the back of the tarm to circulate water from the Tarm to the storage tank. Then there is a circulator with zone valve between the tank and the rest of the house heating system which as I said is set up so each zone has a circulator.

Any suggestions. My house gets to be 80 degrees because one zone is calling for heat.

I'm sure this isn't enough info to be useful. I have a circulator on the back of the tarm to circulate water from the Tarm to the storage tank. Then there is a circulator with zone valve between the tank and the rest of the house heating system which as I said is set up so each zone has a circulator.

Any suggestions. My house gets to be 80 degrees because one zone is calling for heat.