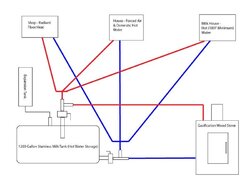

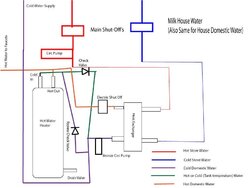

Hi all, I am getting ready to build a homemade wood gasification boiler for our farm to heat the house, shop, and milk house domestic water. This system uses a 1200 gallon stainless bulk tank for thermal storage (pressurized is my goal) and a homemade gasifier for supply. I plan to run the system even in summer to heat DHW for the house and milk-house (a big hot-water consumer)....

Eventually I'll had some solar collectors to the mix as well..

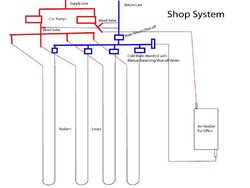

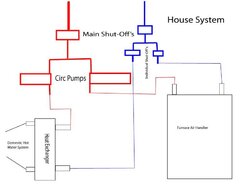

I have drawn up some plumbing schematics in Adobe Illustrator (pardon my sad drawing skills! ) for you folks to look over and critique for me..

Thanks in advance for any comments/criticism..

-Matt

Newbie Boiler Man!

Eventually I'll had some solar collectors to the mix as well..

I have drawn up some plumbing schematics in Adobe Illustrator (pardon my sad drawing skills! ) for you folks to look over and critique for me..

Thanks in advance for any comments/criticism..

-Matt

Newbie Boiler Man!