Looking at Home Depot they show multiple types of Durock including this product: http://www.homedepot.com/h_d1/N-5yc...splay?langId=-1&storeId=10051&catalogId=10053 .. No mention of Nexgen in the pic but they do offer the the 3'x5'x1/2" Nexgen product.. If this is the original stuff that would be great!

Ray

Ray

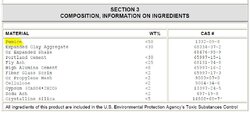

so let me try to clarify any confusion ... I'm just sharing what the technicians at USG told me through several calls where I was essentially repeating the same questions because I basically couldn't comprehend why they were conflicting their own technical papers like the one that BeGreen posted and other things like the MSDS sheets which simply don't say anything at all about polystyrene but basically only list other than the typical things like cement, sand and shale a "proprietary mineral blend". Still technician tolds me that they do put polystyrene in there to lighten the load.

so let me try to clarify any confusion ... I'm just sharing what the technicians at USG told me through several calls where I was essentially repeating the same questions because I basically couldn't comprehend why they were conflicting their own technical papers like the one that BeGreen posted and other things like the MSDS sheets which simply don't say anything at all about polystyrene but basically only list other than the typical things like cement, sand and shale a "proprietary mineral blend". Still technician tolds me that they do put polystyrene in there to lighten the load.