Oh you Garn guys have really got religion. I admire that. I suspect termite got himself a really good "cold war downdraft boiler" and a pretty cool, discrete storage tank to boot, for less than the retail on your favorite boiler, and had fun installing it all himself, to boot.

Outdoor Biomax 60 installation complete (pictures attached)

- Thread starter termite

- Start date

-

Active since 1995, Hearth.com is THE place on the internet for free information and advice about wood stoves, pellet stoves and other energy saving equipment.

We strive to provide opinions, articles, discussions and history related to Hearth Products and in a more general sense, energy issues.

We promote the EFFICIENT, RESPONSIBLE, CLEAN and SAFE use of all fuels, whether renewable or fossil. -

Super Cedar firestarters 30% discount Use code Hearth2024 Click here

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Status

- Not open for further replies.

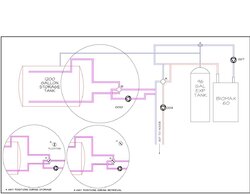

Here's the plumbing diagram I promised Don L. I'll post the electrical schematic tomorrow.

Eric, I'm not sure what was in the tank before but it has a concrete lining. I think it was a boiler blowdown tank.

Garnification, I agree simple is better. I tried to make it as simple as possible and still provide the functionality I wanted. In retrospect I probably should have looked a little harder at a Garn considering the time and money I have invested. Oh well. Did High E's tank have the manway cover? I had to fabricate one.

Eric, I'm not sure what was in the tank before but it has a concrete lining. I think it was a boiler blowdown tank.

Garnification, I agree simple is better. I tried to make it as simple as possible and still provide the functionality I wanted. In retrospect I probably should have looked a little harder at a Garn considering the time and money I have invested. Oh well. Did High E's tank have the manway cover? I had to fabricate one.

Attachments

Eric Johnson said:Oh you Garn guys have really got religion. I admire that. I suspect termite got himself a really good "cold war downdraft boiler" and a pretty cool, discrete storage tank to boot, for less than the retail on your favorite boiler, and had fun installing it all himself, to boot.

You know, I think if you downdrafters were to install and operate a Garn, I think you guys would have to get a second job with all of the free time you will have on your hands. just kiddin'. I asked this question before but don't remember if I got an answer. What is the life expentancy of the nozzle and secondary refractory of the downdrafters. According to a Tarm dealer, he said that they recommend nozzle replacement after 4-5 years. Is this true for other downdrafters? I seen a Tarm solo 40 in service. It has a nice fit and finish and burns clean and quiet. But after seeing and hearing a Garn burn, its like comparing a cutting torch to a Big lighter. Amen!

They say you get five years out of a nozzle in an EKO. They cost $50 each to replace. My boiler has two.

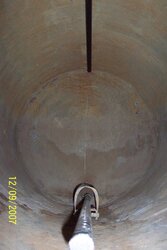

Some tank photos for your viewing pleasure. Manway cover is made of 1/2" steel and 3/4" bolts. It seems to be holding up pretty well. There is no measurable deflection or leaks at 18psi and full fill. I haven't heated the tank up all the way but it works well so far. Also shown are the manifolds I installed in the tank.

Attachments

Howdja like to be the guy who skimmed that layer of cement in there? I bet that gives you a little more storage mass. Neutralize your water, too.

What does that tank weigh?

What does that tank weigh?

Eric,

I'm not sure what it weighs. It's very heavy. The lining is built up to about 3/4". I left the sheathing off the back of the building and pulled it up into the building with a block and tackle stretched across the creek to a large tree (1/2" cable, double block, ratcheting come along, long day). I hope the lining helps.

I'm not sure what it weighs. It's very heavy. The lining is built up to about 3/4". I left the sheathing off the back of the building and pulled it up into the building with a block and tackle stretched across the creek to a large tree (1/2" cable, double block, ratcheting come along, long day). I hope the lining helps.

termite said:Here's the plumbing diagram I promised Don L. I

Thanks for the diagram! Much appreciated.

Some observations on firing:

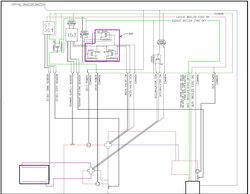

I seen in an earlier thread that reihart was getting a "FUEL" message on his RK-2001U controller during fires. Same here. The controller was set by default to check that the boiler has reached operating temp within one hour of starting. If it doesn't you will get the "FUEL" message and fans will stop. Also it will give the "FUEL" message if, after reaching operating temp, the boiler drops back below it and stays there for 30 minutes. Both of these conditions are likely if you are charging a tank. I set both of these values in the controller to 4hrs and get no more fuel messages. Boiler just keeps on cranking. Thought you guys who are talking about getting one of these for your EKO's might like to know this.

Other than that this thing is a beast so far. I built a wood/coal fire yesterday that kept the boiler between 173-192 degrees for hours. The fan cover is off the boiler in the photo so I can get the fan dialed in. I have the tank at 145 on the bottom and 165 2/3 the way up. I'm going put another thermistor on the very top of the tank and insulate it today if I can stand the heat.

I seen in an earlier thread that reihart was getting a "FUEL" message on his RK-2001U controller during fires. Same here. The controller was set by default to check that the boiler has reached operating temp within one hour of starting. If it doesn't you will get the "FUEL" message and fans will stop. Also it will give the "FUEL" message if, after reaching operating temp, the boiler drops back below it and stays there for 30 minutes. Both of these conditions are likely if you are charging a tank. I set both of these values in the controller to 4hrs and get no more fuel messages. Boiler just keeps on cranking. Thought you guys who are talking about getting one of these for your EKO's might like to know this.

Other than that this thing is a beast so far. I built a wood/coal fire yesterday that kept the boiler between 173-192 degrees for hours. The fan cover is off the boiler in the photo so I can get the fan dialed in. I have the tank at 145 on the bottom and 165 2/3 the way up. I'm going put another thermistor on the very top of the tank and insulate it today if I can stand the heat.

Attachments

Yeah, that's a pretty big radiator you've got heating your boiler room.

I found on my EKO that the factory air settings were all too low for my situation. I was getting wispy smoke beyond startup at times. Opening up the secondary air valves a few turns solved that problem. Now it doesn't even smoke during idle most of the time.

Have you run a wood-fired boiler before, termite? I remain amazed at the difference. With the extra heat, it's almost like having a new house.

I found on my EKO that the factory air settings were all too low for my situation. I was getting wispy smoke beyond startup at times. Opening up the secondary air valves a few turns solved that problem. Now it doesn't even smoke during idle most of the time.

Have you run a wood-fired boiler before, termite? I remain amazed at the difference. With the extra heat, it's almost like having a new house.

Termite,

Nice looking setup. I have a question. I think the TV-160 holds 80 gal, but you said you had a 60 gal E-tank. In one diagram it show a 96 gal E-tank. What expansion tank are U using? Sorry to ask the same question twice, but I am easily confused?

Bill

Nice looking setup. I have a question. I think the TV-160 holds 80 gal, but you said you had a 60 gal E-tank. In one diagram it show a 96 gal E-tank. What expansion tank are U using? Sorry to ask the same question twice, but I am easily confused?

Bill

Eric,

This is my first experience with a gasification boiler. I've been showing it to my friends who still have OWB's. They are blown away by the fact that even when burning coal there is no smoke. I haven't idled much yet. Lots of heat.

ABGWD4U,

Yes, its a Cash-Acme TV-160. Their spec sheet lists it a having 96gal capacity with 64 gallons of acceptance volume.

This is my first experience with a gasification boiler. I've been showing it to my friends who still have OWB's. They are blown away by the fact that even when burning coal there is no smoke. I haven't idled much yet. Lots of heat.

ABGWD4U,

Yes, its a Cash-Acme TV-160. Their spec sheet lists it a having 96gal capacity with 64 gallons of acceptance volume.

Attachments

That's a mighty awesome project termite. It's great to see this thread. The documentation and photo accompaniment for these installations must be a first for the internet. It's inspiring. Makes me want to hook up a boiler just to play with all those pipes again. Keep up the good works folks!

We're a dedicated bunch, BG. Wish this forum existed when I was shopping for a gasifier last year. I'm amazed at all the interest we've seen since getting the Boiler Room going. Apparently there was some pent-up demand for information in this department. I't great to be able to compare notes with other owners from all over the country running different kinds of equipment.

Did your BIL ever get a boiler? I think you said he was considering one.

Did your BIL ever get a boiler? I think you said he was considering one.

Eric Johnson said:We're a dedicated bunch, BG. Wish this forum existed when I was shopping for a gasifier last year. I'm amazed at all the interest we've seen since getting the Boiler Room going. Apparently there was some pent-up demand for information in this department. I't great to be able to compare notes with other owners from all over the country running different kinds of equipment.

.

This group has been an indispensable source of knowledge for me. Where else are there knowledgeable people so willing to show and tell all in an area that is not so well understood by many. My background has been electronics, computer hardware, and network design. I don't have any experience with boilers, pump, piping etc. I do hope that once I have learned enough to get my boiler up and running well I will have learned enough to help others on this form who are in the same position I am in now.

Eric Johnson said:We're a dedicated bunch, BG. Wish this forum existed when I was shopping for a gasifier last year. I'm amazed at all the interest we've seen since getting the Boiler Room going. Apparently there was some pent-up demand for information in this department. I't great to be able to compare notes with other owners from all over the country running different kinds of equipment.

Did your BIL ever get a boiler? I think you said he was considering one.

Yeah, it's neat to see the energy here. I have sent a couple friends over to learn before designing and installing.

My BIL solved his problems for now, so he is sticking with his current setup. I've told him about the forum and hope he'll join in and contribute.

I should have said "the world" instead of "the country," Don. My apologies to our Canadian members and anyone else--anywhere else--who is into alternative central heat. It would be nice to get some English-speaking Poles and Czechs and Danes, Finns, Swedes and others who know a lot more about this stuff than we do, to participate. And can't forget the Germans and Austrians.

Don L,Don L said:I have been looking at the Steca 301 Manual that is being used to monitor temperature on the 1200 gallon tank. Can the Max temp of 140 set at the factory be changed? If so how.

Yes the Steca 301's maximum T2 (bottom of tank) sensor temp is 205 degrees. It's programmable via the three buttons on the front.

termite said:leaddog,

Very toasty indeed. I have a bunch of that black foam stuff you see on the feed water line. For the tank I have 2.5"x4'x8' sheets of log cabin roof insulation and R33 fiberglass batts. Do you have any suggestions on a radiant barrier (material, placement) for the tank?

Radiant barrier requires an air gap, ideally with a low emissivity material on both sides of the gap. 3/4" is pretty near ideal for gap width, and aluminum foil is about as good as it gets for low emissivity material. On a vertical surface, you need some horizontal baffles to break up the convection currents that will otherwise form. You want your radiant barrier at the points with the greatest temperature differential - right at the tank and right at the outside, most likely. The foil needs to be protected from moisture, though, or it will get chalky and not work any more.

I bought a commercial restaurant aluminum foil roll from Costco. 3M makes a spray adhesive that you can get at auto part stores that's awesome for attaching aluminum foil to flat surfaces.

I used strips of foam as spacers on my flat surfaces. On curved surfaces, I used bubble wrap with the bubbles facing the foil.

Foil faced foam board with air gaps works great, too. The secret is making sure that there is no air flow through the gap - you don't want to make little chimneys that convect heat out of your insulation. Seal tops and bottoms aggressively.

It's also really important to control evaporation, or that will not only carry heat away, but also condense inside your insulation and get it wet and thermally conductive. I threw some wax on the surface and floated a sheet of EPDM on that, caulked to the tank lip.

I finally got hard data. My tank is outdoors, and loses about 1 degree per day per 100 degrees temperature difference (water to outside air). Hope you do even better.

That's a pressurized tank he's got there, nofossil. I don't think evaporation is going to be a problem.

Thanks for the insulation tips nofossil. I'm about half way through insulating now. Thankfully I've applied some of what you suggested. The tank is in a building with 2x6 R19 walls and R49 in ceiling above tank. Inside the building, around the tank, I'm putting 2.5" thick log cabin roof insulation on the walls. I put foil on one wall where there would be a gap to the insulation. On the top of the tank I have a layer of R30 then a layer of the silver hvac bubble wrap then another layer of R30 on top of that. On the sides and bottom of the tank I intend to put R19 against tank, then hvac bubble wrap, then the log cabin insulation. I'm walling off the tank from the boiler to make it easier to insulate. Do you think all this will keep it hot?

Termite,,, I'm a believer. I think that tank will be hot and stay hot. I think you could launch it to outer space and it would survive the re-entry into our atmosphere. Nice job,,, well done..... Seyiwmz

- Status

- Not open for further replies.

Similar threads

- Replies

- 7

- Views

- 2K

- Replies

- 36

- Views

- 6K

- Replies

- 12

- Views

- 3K

- Replies

- 18

- Views

- 3K