My P43 will not light, even when doing a manual start. I am able to use gel and have a fire going, but it never goes beyond that.

Is the combustion blower multi-speed? Seems to me that under normal conditions after the igniter gets some pellets lit, the combustion blower ramps up.

The combustion blower is running, but I am wondering if it should pick up in speed.

I am thinking that if what I said is true, then I might have an ESP issue in that it does not detect the heat from the manual light-up?

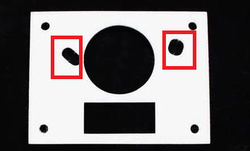

I was going to get another ESP probe to try out. Mine is totally clean (in fact, I am wondering if I broke it because I just cleaned it). To replace it, do I need to remove the controller card?

TIA,

Seth

Is the combustion blower multi-speed? Seems to me that under normal conditions after the igniter gets some pellets lit, the combustion blower ramps up.

The combustion blower is running, but I am wondering if it should pick up in speed.

I am thinking that if what I said is true, then I might have an ESP issue in that it does not detect the heat from the manual light-up?

I was going to get another ESP probe to try out. Mine is totally clean (in fact, I am wondering if I broke it because I just cleaned it). To replace it, do I need to remove the controller card?

TIA,

Seth