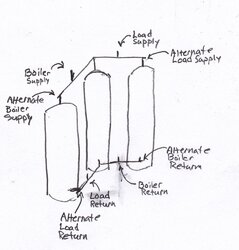

I am trying to decide on the exact location of my three vertical pressurized storage tanks. I need some advice. The tanks will be located in a corner. One tank will be in the corner with one tank on either side. What I need to know is at what angle do I put the inside corner tank. I can turn it at the same angle as the first one or I can turn it so its at a 45 degree angle from the two other tanks. I understand this is a confuseing question. All three tanks are the same with top and bottom fittings for a parallel pipeing setup. If the corner tank was turned the same as the first I dont know how it will match up for pipe length to the third tank. The hot water in/out is on the very top of the tank and the return is on the side ,but near the bottom. Basically my tanks will be L shaped configuration with flow on the top and return out the bottom side. Will this work?

Pressurized storage question?

- Thread starter jimdeq

- Start date

-

Active since 1995, Hearth.com is THE place on the internet for free information and advice about wood stoves, pellet stoves and other energy saving equipment.

We strive to provide opinions, articles, discussions and history related to Hearth Products and in a more general sense, energy issues.

We promote the EFFICIENT, RESPONSIBLE, CLEAN and SAFE use of all fuels, whether renewable or fossil.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Status

- Not open for further replies.

That triangular setup doesn't sound like it will be easy to pipe. Can you put them one after the other along the wall? That will be much easier. If you need to save the space & use the corner maybe metalhose will help, Randy

Middle tank at 45 degrees might work easier.

Come out to a tee on the face of the bottom of the middle tank and head off to the other two tanks with 45 degree street elbows.

Likewise on the top. Come up to a tee on the middle tank that is at 45 degrees to the walls and then head off to the tops of the other two tanks with 45 degree street elbows. [Or better yet a side outlet 90 at the top of the middle tank.]

For symmetry you can use one opposite ends of the two L-shaped manifolds. One pair for heating and the other pair for loading.

--ewd

Come out to a tee on the face of the bottom of the middle tank and head off to the other two tanks with 45 degree street elbows.

Likewise on the top. Come up to a tee on the middle tank that is at 45 degrees to the walls and then head off to the tops of the other two tanks with 45 degree street elbows. [Or better yet a side outlet 90 at the top of the middle tank.]

For symmetry you can use one opposite ends of the two L-shaped manifolds. One pair for heating and the other pair for loading.

--ewd

Hey Singed, I cant go in a line along one wall, I have to use the corner. EW, what do you mean by a " side outlet 90"? Anyone else have comments?

jimdeq said:EW, what do you mean by a " side outlet 90"? Anyone else have comments?

If you scroll down you can find an example (not that you'd want galvanized):

http://www.plumbingsupply.com/galvanizedfittings.html

Probably not something you'll find in the big box, but I think I've seen them in places like F W Webb.

Cheers --ewd

I used radiator hose (from an auto parts store) with hose barbs for 2 year on my pressurized storage to make wide corners and to eliminate difficult fittings. I believe the hose was rated at 250F. Not aware of any problem. With my new shop and a much easier setup, I no longer use the hose.

I didn't think of that, it's a hell of lot cheaper than metal hose, Randyjebatty said:I used radiator hose (from an auto parts store) with hose barbs for 2 year on my pressurized storage to make wide corners and to eliminate difficult fittings. I believe the hose was rated at 250F. Not aware of any problem. With my new shop and a much easier setup, I no longer use the hose.

I inspected the radiator hose after the two years of use and did not notice any softening or other break down of the hose material. It appeared to be in about as good of condition as it was when I first used it. It tends to stick to the hose barbs after being used for awhile and can be difficult to remove from the barbs. The solution is to use hose a little longer than you actually need; that way you can cut the hose barb off if you need to disassemble the setup and still have enough hose to reassemble again.

I am going to take EW's advice and 45 the middle tank. I will put union ball valves on everything just in case. One more quick question. If Im only doing one run of parallel on top should I run another parallel above it that would tee above the middle tank ( main supply coming in and out) and go half way to both outside tanks then 90 down to the main header and tee into that half way between the tanks? Would this give me perfect flow through all tanks due to having all pipes the same length. Basically it would be 3 to 2 to 1 centered.

jimdeq said:I am going to take EW's advice and 45 the middle tank. I will put union ball valves on everything just in case. One more quick question. If Im only doing one run of parallel on top should I run another parallel above it that would tee above the middle tank ( main supply coming in and out) and go half way to both outside tanks then 90 down to the main header and tee into that half way between the tanks? Would this give me perfect flow through all tanks due to having all pipes the same length. Basically it would be 3 to 2 to 1 centered.

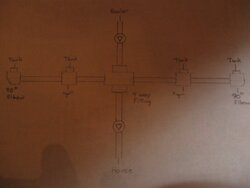

I think you can tee symmetrically most anywhere along the top-bottom opposite pairs of legs. Alternatively the boiler can go straight in the end of the top manifold and out the opposite end of the bottom manifold, and vice versa for the load. Maybe the picture will help.

As I understand it the purpose of separating the boiler and load connections is to help guarantee the pressures in the two separate loops can't interact.

I can't find the pictures, but I think it was sdrobertson who fanned out separate pex lines from remote manifolds. This might be a slicker way to go. I didn't have a whole lot of trouble fitting up black iron to mine, but it seemed like it could have been a whole lot worse if I hadn't been fortunate enough to have some reasonably square and true connection points on the tanks.

Attachments

Thanks again EW' How about this? What if I placed a 4 way cross tee straight out from the middle tank. I was able to turn the two outside tanks toward the middle tank so that all fittings were grouped together in front the middle tank (on the bottom). A 4 way cross would equalize all pipes exactly and allow a port for retern line. The same thing could be done on top ,but pipeing woulb be a little longer due to top ports. The cross on top would also allow for supply. Will this work ? I hope it will because it would be simple to pipe. Then I would just have to establish where to come off for the zones.

jimdeq said:Thanks again EW' How about this? What if I placed a 4 way cross tee straight out from the middle tank. I was able to turn the two outside tanks toward the middle tank so that all fittings were grouped together in front the middle tank (on the bottom). A 4 way cross would equalize all pipes exactly and allow a port for retern line. The same thing could be done on top ,but pipeing woulb be a little longer due to top ports. The cross on top would also allow for supply. Will this work ? I hope it will because it would be simple to pipe. Then I would just have to establish where to come off for the zones.

Cool, and a new jungle-gym as bonus! Just put a tee in one of the side legs at the top to pull load supply and another tee on the opposite bottom side leg for load return and you're done. The load connections wouldn't be perfectly equal, but the flow rate is presumably quite a bit lower, and the equal/symmetrical requirement is after all only a goal, not a show-stopper.

--ewd

Like the idiot I am, I didn't take any photos of my manifolds when I was assembling them but here is a drawing of them. This drawing is of my hot supply manifold (hot from boiler/hot to the house zone) going to the top of my 4 tanks. The other manifold is for the bottom of the tanks which is exactly the same but without the circulators. All of my lines going from the manifolds to the tanks are all cut the same length and I get pretty consistence loading of all 4 tanks. The beauty of this setup is that the house zone doesn't care where it gets its water supply from....it either comes from the boiler (if its running) or the storage tanks. I made them from 1 inch black pipe.

*Edit* If you hook up using this method, you will need a way to isolate the boiler when it is not running as you want the water to come from the tanks. I'm using a motorized valve that only opens when the water is 187 degrees out of the boiler.

*Edit* If you hook up using this method, you will need a way to isolate the boiler when it is not running as you want the water to come from the tanks. I'm using a motorized valve that only opens when the water is 187 degrees out of the boiler.

Attachments

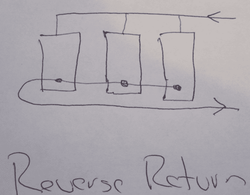

if you want equal flow thru all tanks, reverse return piping is another method. It does require more pipe and insulation.

Basically the first tank to get supply is the last to return. Some installers step the pipe size to get more accurate flow with less pipe diameter costs.

hr

Basically the first tank to get supply is the last to return. Some installers step the pipe size to get more accurate flow with less pipe diameter costs.

hr

Attachments

WOW THANKS FOR ALL THE IMPUT AND DRAWINGS. I like the easiness of the cross idea, but reverse return seems more proven for equal flows. EW states unequal not a total deal breaker,but I want to do this as efficient as possible. Here's the question? In hot water, describes reverse return,but what if the lengths on the top manifold do not equal the lengths on the bottom manifold. My top manifold will be coming out of the top of the tanks in a L shaped pattern, but my bottom manifold will be out of the side about one foot up from the bottom of the tanks. If I turn the tanks so the bottom ports are facing each other the lengths would be drastically shortened. Would long manifolds on the top and short manifolds on the bottom disrupt the flow and balancing?

The lines will only have to equal with each manifold that they are serving. The lines can be different length between the two manifolds, just make sure they are equal on the same manifold. The manifolds can even be different length. The water doesn't care where it is coming from, or where its going, just that it can move.

jimdeq said:WOW THANKS FOR ALL THE IMPUT AND DRAWINGS. I like the easiness of the cross idea, but reverse return seems more proven for equal flows. EW states unequal not a total deal breaker,but I want to do this as efficient as possible. Here's the question? In hot water, describes reverse return,but what if the lengths on the top manifold do not equal the lengths on the bottom manifold. My top manifold will be coming out of the top of the tanks in a L shaped pattern, but my bottom manifold will be out of the side about one foot up from the bottom of the tanks. If I turn the tanks so the bottom ports are facing each other the lengths would be drastically shortened. Would long manifolds on the top and short manifolds on the bottom disrupt the flow and balancing?

Your cross design offers the best/most equal connections for the boiler, which what matters most, but you'd be compromising somewhat on the load connections.

If you'll notice, my drawing above with shows both the symmetrically placed tees and the reverse return options, take your pick. With either the symmetrically placed tees or the reverse return there is a slight difference in the path lengths, but for as many millipascals difference as it would make at some point you need cut some threads and fit some pipe before snow flies.

Cheers --ewd

ewdudley said:jimdeq said:WOW THANKS FOR ALL THE IMPUT AND DRAWINGS. I like the easiness of the cross idea, but reverse return seems more proven for equal flows. EW states unequal not a total deal breaker,but I want to do this as efficient as possible. Here's the question? In hot water, describes reverse return,but what if the lengths on the top manifold do not equal the lengths on the bottom manifold. My top manifold will be coming out of the top of the tanks in a L shaped pattern, but my bottom manifold will be out of the side about one foot up from the bottom of the tanks. If I turn the tanks so the bottom ports are facing each other the lengths would be drastically shortened. Would long manifolds on the top and short manifolds on the bottom disrupt the flow and balancing?

Your cross design offers the best/most equal connections for the boiler, which what matters most, but you'd be compromising somewhat on the load connections.

If you'll notice, my drawing above with shows both the symmetrically placed tees and the reverse return options, take your pick. With either the symmetrically placed tees or the reverse return there is a slight difference in the path lengths, but for as many millipascals difference as it would make at some point you need cut some threads and fit some pipe before snow flies.

Cheers --ewd

This is very true in that you can decipher, analize, and then decipher some more but I found that I had to just pick up the pipe and start building. Once you get going, its allot easier to make your decisions.

- Status

- Not open for further replies.

Similar threads

- Replies

- 10

- Views

- 2K

- Replies

- 12

- Views

- 2K

- Replies

- 5

- Views

- 1K

- Replies

- 16

- Views

- 5K