I am working on finalizing the plan for the re-work of my system, the Eko and floor heat have worked very well for the last two seasons and now I want to graduate to a system with back-up and storage. Everything has run without any added controls so-far other than the Eko control and a miximizer for the floor heat.

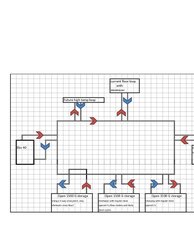

The challenge is working in the storage charge and discharge with close spaced t's. In my mind this does not work since I will use two circ's to reverse the flow through the coils to save cost. (both check valves removed) ( there is the Dutch in me ;-) ) When I hook it up the normal way, it should charge correctly, but at discharge it would short cycle due to the fact that the primary loop keeps going clockwise. ( I attached a file to illustrate this all, the 3 tanks are the 3 scenarios)

The idea I got was to use a Taco Twin-Tee and fix it that way, the tee is than not in-line but side by side and should stop the short cycle. When I checked for cost and availability, I first got sticker shock and than they said it would be at least a few more weeks to get it ( not a stock item anymore in Canada)

The following idea is not tried but straight from the farm engineering department. I am thinking of using a 1" brass cross piece in place of the Twin Tee, I hope this reduces the cross flow but I am considering placing a "baffle" from the top of the one sec.port to the bottom of the other sec. port.

The question is, would this work?

Any comments welcome,

Henk.

The challenge is working in the storage charge and discharge with close spaced t's. In my mind this does not work since I will use two circ's to reverse the flow through the coils to save cost. (both check valves removed) ( there is the Dutch in me ;-) ) When I hook it up the normal way, it should charge correctly, but at discharge it would short cycle due to the fact that the primary loop keeps going clockwise. ( I attached a file to illustrate this all, the 3 tanks are the 3 scenarios)

The idea I got was to use a Taco Twin-Tee and fix it that way, the tee is than not in-line but side by side and should stop the short cycle. When I checked for cost and availability, I first got sticker shock and than they said it would be at least a few more weeks to get it ( not a stock item anymore in Canada)

The following idea is not tried but straight from the farm engineering department. I am thinking of using a 1" brass cross piece in place of the Twin Tee, I hope this reduces the cross flow but I am considering placing a "baffle" from the top of the one sec.port to the bottom of the other sec. port.

The question is, would this work?

Any comments welcome,

Henk.