Summer planning project here on a cold winter night .

OK guys I need a plan and a grocery list to hook up heating my hot tub year around from my wood boiler heating system .

Here is my set up , I currently have a Solo 60 and 1200gal unpressurized storage . Boiler is in attached garage storage tank is in basement , I am heating with 5 zones , basement , first floor , upstairs 2nd floor and a large 640 sq ft sun room which is like heating a corn crib , it has 2 zones in floor radiant and 2 water to air heaters ( this room we only heat on the weekends and when it is above zero , hey and don't laugh I also have a pellet stove in here too yet ). The system runs a glycol mixture , the storage tank is currently charged with 3-3/4 loops and I have 0ne 3/4 loop for on demand DHW.

The hot tub is in the sun room which I maintain a minimum of 35 up to normal 72 -75 on weekends . The hot tub is 500 gal 7 person insulated outside tub .

It costs me about 25 a month just to keep this thing hot .

Now that I have this boiler and setup this is an after thought . We currently use this year around for DHW and now after the fact I am thinking of using it to heat my hot tub also .

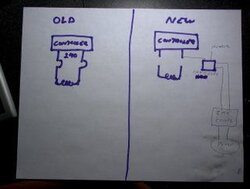

OK here is my plan sort of and that is to use my DHW coil for heating my DHW and a heat exchanger to heat hot tub , and I may only be able to run 3/8 pex to the hot tub

Does anyone have an idea what I use for pumps , heat exchanger ,and controller any other ideas are welcome and if you have any questions about my set up .

I don't want to waste money on an over kill and don't want to fall short on a system either .

Thanks for all your help before hand .

Steve

OK guys I need a plan and a grocery list to hook up heating my hot tub year around from my wood boiler heating system .

Here is my set up , I currently have a Solo 60 and 1200gal unpressurized storage . Boiler is in attached garage storage tank is in basement , I am heating with 5 zones , basement , first floor , upstairs 2nd floor and a large 640 sq ft sun room which is like heating a corn crib , it has 2 zones in floor radiant and 2 water to air heaters ( this room we only heat on the weekends and when it is above zero , hey and don't laugh I also have a pellet stove in here too yet ). The system runs a glycol mixture , the storage tank is currently charged with 3-3/4 loops and I have 0ne 3/4 loop for on demand DHW.

The hot tub is in the sun room which I maintain a minimum of 35 up to normal 72 -75 on weekends . The hot tub is 500 gal 7 person insulated outside tub .

It costs me about 25 a month just to keep this thing hot .

Now that I have this boiler and setup this is an after thought . We currently use this year around for DHW and now after the fact I am thinking of using it to heat my hot tub also .

OK here is my plan sort of and that is to use my DHW coil for heating my DHW and a heat exchanger to heat hot tub , and I may only be able to run 3/8 pex to the hot tub

Does anyone have an idea what I use for pumps , heat exchanger ,and controller any other ideas are welcome and if you have any questions about my set up .

I don't want to waste money on an over kill and don't want to fall short on a system either .

Thanks for all your help before hand .

Steve