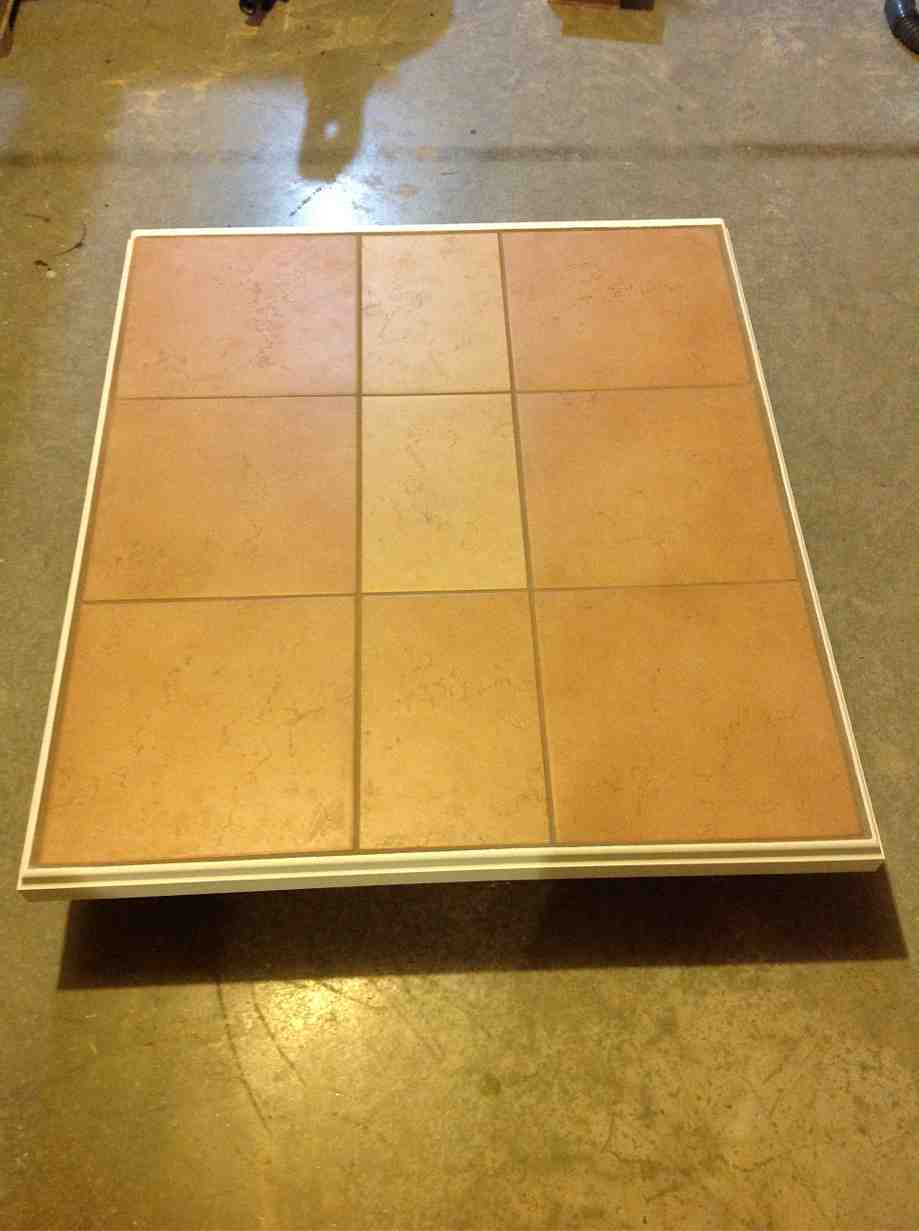

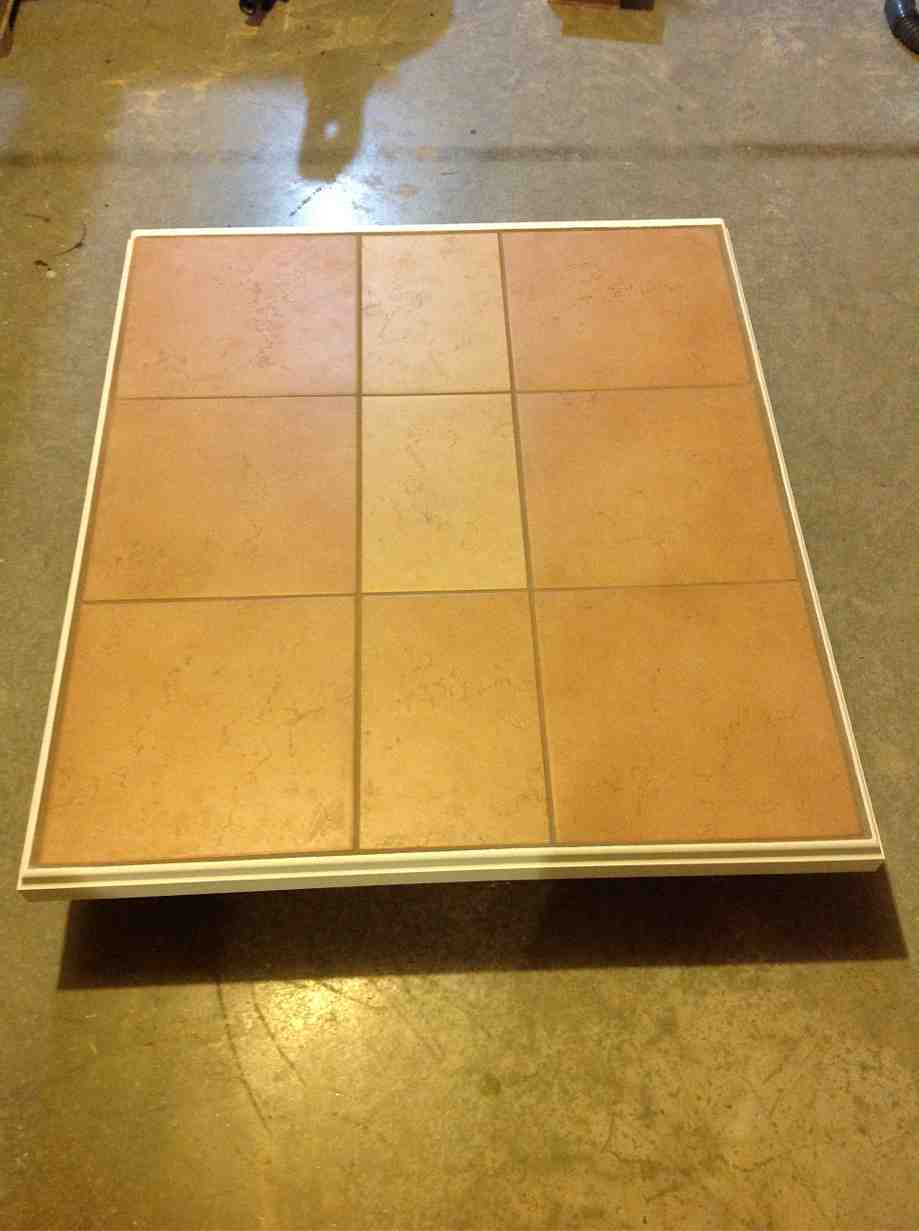

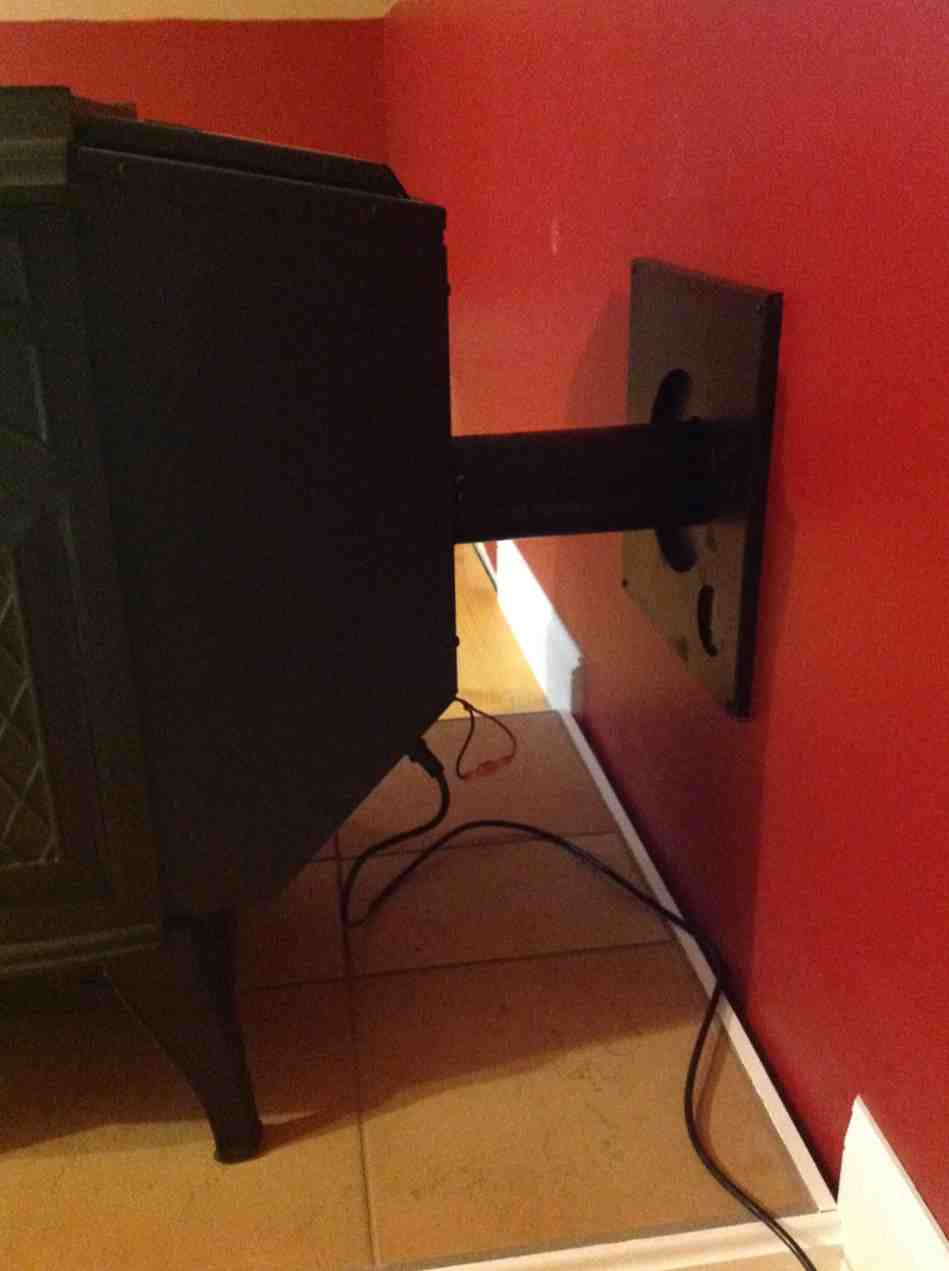

I'm installing a Quad Castile in the upstairs family room and thought that I should share some photos. I should have the install finished and stove running tomorrow. The only thing that will be left to do is the OAK. I still need to order a couple of parts for that.

I will have more pictures to share tomorrow. I'm pretty excited to get this stove running. It should definitely help to keep the upstairs nice and toasty.

I will have more pictures to share tomorrow. I'm pretty excited to get this stove running. It should definitely help to keep the upstairs nice and toasty.

Well done!

Well done!