This year I started burning wood in a new Enviro 1700. My temp gauge placement is on the front top of the door. I assumed (possibly incorrectly) that this position reads lower temps then I would receive on the top of the insert.

Anyhow, I was hesitant to fire the stove at temps which made the secondary tubes glow. The few times they have, I get a sweet secondary burn and the temp gauge reads about 400-500 degrees. When this happens I can hear the stove expanding which also makes me a little worried that I'm overfiring.

The past couple weeks I've started to analyze how I'm burning the stove because I now have major problems with smoke back whenever I open the door. The screen on the top of the chimney cap and the bottom of the cap itself are blackened with tar and I'm wondering if this is due to the temps I'm burning at.

As I sit here now, I have three splits in a hot stove that has been burning all day and with the air wide open I'm unable to get the gauge above 400 degrees.

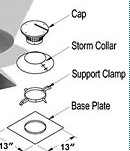

I installed the stove myself because I wanted to use a factory insulated double wall liner and couldn't find a dealer who was interested in putting it in. I'm using 17 ft of Simpson Duraliner (rigid, 6" double walled), 5 ft of flexible stainless to get through the throat of the chimney, Kaowool insulation at the top and the bottom, and a 45 degree stove pipe connector between the insert and the flexible stainless. Every connection has been sealed with stovepipe cement.

I think that I will quit burning the stove on tomorrow and clean the chimney on Sunday to see if that helps anything. Does anybody have any recommendations? Criticism and advice is appreciated.

Thank you in advance

Anyhow, I was hesitant to fire the stove at temps which made the secondary tubes glow. The few times they have, I get a sweet secondary burn and the temp gauge reads about 400-500 degrees. When this happens I can hear the stove expanding which also makes me a little worried that I'm overfiring.

The past couple weeks I've started to analyze how I'm burning the stove because I now have major problems with smoke back whenever I open the door. The screen on the top of the chimney cap and the bottom of the cap itself are blackened with tar and I'm wondering if this is due to the temps I'm burning at.

As I sit here now, I have three splits in a hot stove that has been burning all day and with the air wide open I'm unable to get the gauge above 400 degrees.

I installed the stove myself because I wanted to use a factory insulated double wall liner and couldn't find a dealer who was interested in putting it in. I'm using 17 ft of Simpson Duraliner (rigid, 6" double walled), 5 ft of flexible stainless to get through the throat of the chimney, Kaowool insulation at the top and the bottom, and a 45 degree stove pipe connector between the insert and the flexible stainless. Every connection has been sealed with stovepipe cement.

I think that I will quit burning the stove on tomorrow and clean the chimney on Sunday to see if that helps anything. Does anybody have any recommendations? Criticism and advice is appreciated.

Thank you in advance

! I guess I shouldn't be so worried about burning too hot? The wood should be better next year too. I cut, split and stacked it this summer so it only has about 6 months of seasoning.

! I guess I shouldn't be so worried about burning too hot? The wood should be better next year too. I cut, split and stacked it this summer so it only has about 6 months of seasoning.