Hello

I have worked on this Harman pellet boiler for many years and it is a very rugged long lasting unit for FHW !!

The flame guide is easily accessible by removing the red handle nut under the hopper and swinging it open just like a Buderus boiler.

This makes servicing and cleaning easier.

The flame guide however is under a insulated foam pad glued on to the bottom of a top plate that is bolted down with 2 number 10 3/4” long self tapping screws. First I wire wheeled the good screw on the right thing break up the corrosion around the edge which can lock it down. Then I sprayed it with PB Blaster to help loosen it up. To my surprise it unscrewed quite easily. However the struggle was far from over. The left side screw was still in the hole in the top plate because the bolt broke off flush. This top plate has tabs on the sides and was designed to pull straight out not up. In this case I had to angle the top plate up to pull the tabs out and get that back hole up enough to get it out of the broken screw! Finally after a long struggle and cutting the silicone sealant away I got it off! Now I really do not want that kind of struggle to get it back on so what do I do? I pulled out the sawzall and started to cut the protruding part of the broken screw. As I started cutting the screw, it became loose! I thought this may be good because it can be just unscrewed out of the hole? Well no dice! Using the vice grips and trying and trying the tip of the self tapper would not pull out! Therefore, using the sawzall again I finished cutting the screw. The body of the screw was cut off and tapping the bottom portion of the screw made it fall threw the hole. Bingo! Luckily I had two new Stainless Steel screws, glued the new foam pad on to the bottom of the top plate, and assembled the new flame guide and cover with the new screws!

So 2 hours for this fix and 2 hours to clean the stove, venting, heat exchanger and ash chamber. Also put a new gasket an the ash chamber cover.

Pic 1 - Harman PB105 Pellet boiler

Pic 2 - Front swings open

Pic 3 - Harman burn pot with badly broken flame guide, worn foam insulated pad and left screw with broken screw head.

Pic 4 - Broken self tapping screw protruding from hole.

Pic 5 - Trying in vain to unscrew and pull out the broken self tapping screw with vice grips. Cutting with the sawzall and banging with an awl and hammer did the trick.

Pic 6 - Shazam! New flame guide, new foam insulated pad and top plate with 2 new 10-3/4” Stainless Steel self tapping screws re-installed!

Pic 7 - huge Ash chamber is chock full! Cover gasket is toast!

Pic 8-9 exhaust blower impeller blades need a good wire wheeling and brushing. Also access for cleaning the ESP probe and exhaust venting.

Pic 10 - new and broken parts

Pic 11 - Harman Flame Guide 3-00-08534

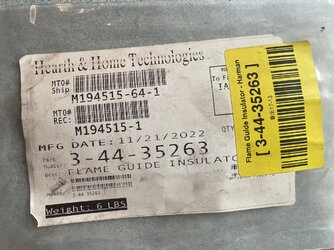

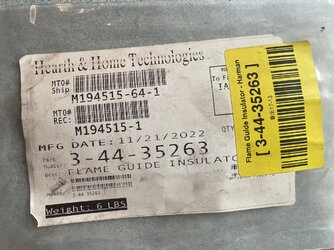

Pic 12 - Harman Flame Guide Insulator (Foam Pad)

Pic 13 - Gasket - 105 (Ash chamber cover gasket)

I have worked on this Harman pellet boiler for many years and it is a very rugged long lasting unit for FHW !!

The flame guide is easily accessible by removing the red handle nut under the hopper and swinging it open just like a Buderus boiler.

This makes servicing and cleaning easier.

The flame guide however is under a insulated foam pad glued on to the bottom of a top plate that is bolted down with 2 number 10 3/4” long self tapping screws. First I wire wheeled the good screw on the right thing break up the corrosion around the edge which can lock it down. Then I sprayed it with PB Blaster to help loosen it up. To my surprise it unscrewed quite easily. However the struggle was far from over. The left side screw was still in the hole in the top plate because the bolt broke off flush. This top plate has tabs on the sides and was designed to pull straight out not up. In this case I had to angle the top plate up to pull the tabs out and get that back hole up enough to get it out of the broken screw! Finally after a long struggle and cutting the silicone sealant away I got it off! Now I really do not want that kind of struggle to get it back on so what do I do? I pulled out the sawzall and started to cut the protruding part of the broken screw. As I started cutting the screw, it became loose! I thought this may be good because it can be just unscrewed out of the hole? Well no dice! Using the vice grips and trying and trying the tip of the self tapper would not pull out! Therefore, using the sawzall again I finished cutting the screw. The body of the screw was cut off and tapping the bottom portion of the screw made it fall threw the hole. Bingo! Luckily I had two new Stainless Steel screws, glued the new foam pad on to the bottom of the top plate, and assembled the new flame guide and cover with the new screws!

So 2 hours for this fix and 2 hours to clean the stove, venting, heat exchanger and ash chamber. Also put a new gasket an the ash chamber cover.

Pic 1 - Harman PB105 Pellet boiler

Pic 2 - Front swings open

Pic 3 - Harman burn pot with badly broken flame guide, worn foam insulated pad and left screw with broken screw head.

Pic 4 - Broken self tapping screw protruding from hole.

Pic 5 - Trying in vain to unscrew and pull out the broken self tapping screw with vice grips. Cutting with the sawzall and banging with an awl and hammer did the trick.

Pic 6 - Shazam! New flame guide, new foam insulated pad and top plate with 2 new 10-3/4” Stainless Steel self tapping screws re-installed!

Pic 7 - huge Ash chamber is chock full! Cover gasket is toast!

Pic 8-9 exhaust blower impeller blades need a good wire wheeling and brushing. Also access for cleaning the ESP probe and exhaust venting.

Pic 10 - new and broken parts

Pic 11 - Harman Flame Guide 3-00-08534

Pic 12 - Harman Flame Guide Insulator (Foam Pad)

Pic 13 - Gasket - 105 (Ash chamber cover gasket)

Last edited: