Hi all,

I want to put an air line from my compressor to the house, for access to air inside the house. the compressor lives in the garage and I have a 50 ft air hose reel. this reaches the wall of the house where i want to install a pipe where i can go out and hook up when i want the air. (i want to use the air mostly to assist in cleaning my pellet stove)

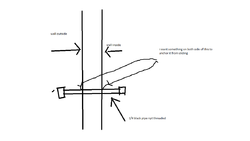

i have 1/4 npt fittings. and i can get an 8" npt black pipe and put it through the wall. add the fittings and this would work perfectly - except - the pipe wouldnt be anchored to the wall in any way, just slideable in that hole held in by its quick connect fittings.

i think my attached drawing says this better than words. any ideas how to go about this? it sure would save me a lot of hassle not to have to run a 100 foot hose through the front door all the time.

If i put flanges on the pipe then i lose the threads where i would put on the fittings.

I want to put an air line from my compressor to the house, for access to air inside the house. the compressor lives in the garage and I have a 50 ft air hose reel. this reaches the wall of the house where i want to install a pipe where i can go out and hook up when i want the air. (i want to use the air mostly to assist in cleaning my pellet stove)

i have 1/4 npt fittings. and i can get an 8" npt black pipe and put it through the wall. add the fittings and this would work perfectly - except - the pipe wouldnt be anchored to the wall in any way, just slideable in that hole held in by its quick connect fittings.

i think my attached drawing says this better than words. any ideas how to go about this? it sure would save me a lot of hassle not to have to run a 100 foot hose through the front door all the time.

If i put flanges on the pipe then i lose the threads where i would put on the fittings.