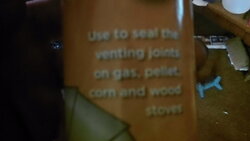

Soooooo......yesterday (24 hours ago ) I sealed the stainless steel adapter to the cast iron wood burning insert and to the stainless steel flex pipe flue. After the forementioned 24 hours I fired up the Vermont Casting insert. I failed to mention that 48 hours ago I fired up the insert to see where I needed to seal my connections, having said that I discovered where the leaks were at the 2 connections and let the stove cool down and then applied the sealant and waited the 24 hours to cure. It now appears that I sealed the connections,however; the connections are still smoking and it appears to be the Rutland black high heat 600 degree RTV silicone sealant.....Not the aroma I was looking for. After burning wood for several hours it appears that the smoking silicone has stopped.Obviously I have a few questions. Is the smoking silicone usual. Shoule I have bought a higher degree rated siline and if so can I apply it over the existing silicone?

smoking silicone

- Thread starter cowboytrail

- Start date

-

Active since 1995, Hearth.com is THE place on the internet for free information and advice about wood stoves, pellet stoves and other energy saving equipment.

We strive to provide opinions, articles, discussions and history related to Hearth Products and in a more general sense, energy issues.

We promote the EFFICIENT, RESPONSIBLE, CLEAN and SAFE use of all fuels, whether renewable or fossil.