Solar cord wood kiln operation

- Thread starter Poindexter

- Start date

-

Active since 1995, Hearth.com is THE place on the internet for free information and advice about wood stoves, pellet stoves and other energy saving equipment.

We strive to provide opinions, articles, discussions and history related to Hearth Products and in a more general sense, energy issues.

We promote the EFFICIENT, RESPONSIBLE, CLEAN and SAFE use of all fuels, whether renewable or fossil.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Today the max temp I read inside load one was 128dF, with outdoor ambients in the shade around +75dF. It is unseasonably hot here, I shouldn't be seeing mid 70s until early June.

Load three is still hanging in the low to mid 90s dF measured, but it is still open at the ends and not under 20% yet.

I think @paul bunion might be on to something since I am not worried about checking and warping. Once I get load four in here and loaded up I am going to air dry it down to FSP with the side curtains rolled up and then just put the screws to it to see what happens.

It is freaking humid inside those units. I pulled clips in a few places so I could slip behind the plastic like a shower curtain and stand "inside" the units with my feet on the lawn, wow, like a jungle in there.

Looking into how I can quantify sunlight exposure. Anemometer to measure wind speed is easy. My best idea for light is three small solar panels, one each facing E-S and W with an ammeter or voltmeter on them to see how much light is hitting the panels. I would like to be able to say, eventually, a load of green freshly felled wood takes X amount of wind and Y amount of sunlight with average temperature of Z to hit 16% MC.

128 degrees in there in May 11th. I am ecstatic.

Load three is still hanging in the low to mid 90s dF measured, but it is still open at the ends and not under 20% yet.

I think @paul bunion might be on to something since I am not worried about checking and warping. Once I get load four in here and loaded up I am going to air dry it down to FSP with the side curtains rolled up and then just put the screws to it to see what happens.

It is freaking humid inside those units. I pulled clips in a few places so I could slip behind the plastic like a shower curtain and stand "inside" the units with my feet on the lawn, wow, like a jungle in there.

Looking into how I can quantify sunlight exposure. Anemometer to measure wind speed is easy. My best idea for light is three small solar panels, one each facing E-S and W with an ammeter or voltmeter on them to see how much light is hitting the panels. I would like to be able to say, eventually, a load of green freshly felled wood takes X amount of wind and Y amount of sunlight with average temperature of Z to hit 16% MC.

128 degrees in there in May 11th. I am ecstatic.

Babaganoosh

Minister of Fire

I ended up doing other things this summer. All the wood, in every module, even the live felled in Feb 2016 is down below 7%MC in late Sept 2016. Seven. I can go from cold stove to engaged cat and clean plume in 10 minutes day after day.

I _think_ I can season two loads per year in each module, but I would need to build a wood shed to move the seasoned wood into. I was down under 20 % everywhere I looked around solstice, June 22. If I get rid of half the modules, I have plenty of room for a wood shed. Waiting to hear from the wife on that one, but the solar kilns are "working awesome" to borrow a phrase.

I _think_ I can season two loads per year in each module, but I would need to build a wood shed to move the seasoned wood into. I was down under 20 % everywhere I looked around solstice, June 22. If I get rid of half the modules, I have plenty of room for a wood shed. Waiting to hear from the wife on that one, but the solar kilns are "working awesome" to borrow a phrase.

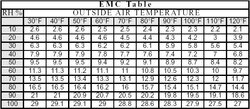

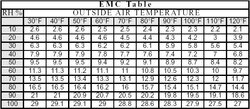

So I am interested in hearing about your experience with EMC (Equillibrium Moisture Content).

I lifted a lovely elegantly formatted table from these guys: http://www.volko.com/crawlspacevent.htm

The data sure looks like it came from the (public domain) US Forest Service, I don't see anything that raises an eyebrow here.

So if you got your wood up in say April and you have sustained temps in the +90s dF for August, with relative humidity around 90% for all of August, your stack probably reached EMC in late June or early July and then will tend towards 19.8% MC during August.

With me so far?

So how fast will cordwood splits in a big pile reach a new different EMC when the weather changes? A couple hours, a week, a month? Two months?

I lifted a lovely elegantly formatted table from these guys: http://www.volko.com/crawlspacevent.htm

The data sure looks like it came from the (public domain) US Forest Service, I don't see anything that raises an eyebrow here.

So if you got your wood up in say April and you have sustained temps in the +90s dF for August, with relative humidity around 90% for all of August, your stack probably reached EMC in late June or early July and then will tend towards 19.8% MC during August.

With me so far?

So how fast will cordwood splits in a big pile reach a new different EMC when the weather changes? A couple hours, a week, a month? Two months?

Last edited by a moderator:

Here is everything I observered between May 11th and Sept 25 in my kilns:

Max temp I ever measured was +142dF. I had about a week in early July when I was seeing 140-141-142 dF right when I got home from work in the late afternoons. How high did they go during the day before I got home, I don't know.

I never yet have had a humidity sensor inside one of these modules; it would be real helpful data right now.

There were a couple nights in late July when we started having some darkness when the plastic over the PVC was ballooned out, as if the wood stacks were emitting enough heat (compared to the cooler evening air) to blow up the kilns like a hot air balloon. A couple is two that I noticed.

That's really all the attention I was able to pay all summer while life had other plans.

The plastic seems to be holding up fine, I think they are still weather tight, except for the gable vents that I haven't moved since installation, and they are still open around the floor perimeter.

Max temp I ever measured was +142dF. I had about a week in early July when I was seeing 140-141-142 dF right when I got home from work in the late afternoons. How high did they go during the day before I got home, I don't know.

I never yet have had a humidity sensor inside one of these modules; it would be real helpful data right now.

There were a couple nights in late July when we started having some darkness when the plastic over the PVC was ballooned out, as if the wood stacks were emitting enough heat (compared to the cooler evening air) to blow up the kilns like a hot air balloon. A couple is two that I noticed.

That's really all the attention I was able to pay all summer while life had other plans.

The plastic seems to be holding up fine, I think they are still weather tight, except for the gable vents that I haven't moved since installation, and they are still open around the floor perimeter.

in early September I pulled a huge sample, six splits from every cord. Three from the south facing side of each cord, three from the north facing side of each cord. One from the top on each side, one from the middle, one from within 18" of grade level, 48 splits in the garage for 48 hours.

Three data points each split on a fresh face, what is that 144 data points? I could hardly get my MM to flicker. 7% MC faintly indicated here and there. That's been an adventure worthy of it's own thread, but it seemed like my stove was either getting acclimated to drier wood, or my stacks are picking up moisture...

So I pulled another good sized sample Thursday afternoon and stuck them in the garage until Sat mid-day.

Just four splits from each cord this time, one from the top, one within 18" of grade. The east end of the east facing splits selected were labeled with an 'E" and so on.

Here is the raw data from my appendiceal module that runs N-S and therefore has an East face and a West face:

FWIW a star (*) entry means less than 7%MC, I don't know how dry...

E *** *** W

E 14-15-14 11-13-15 W

So only one cord left in that module, pretty sure the ones from on top are still too dry to measure, it is the ones closer to grade level that are a leetle bit heavier.

Three data points each split on a fresh face, what is that 144 data points? I could hardly get my MM to flicker. 7% MC faintly indicated here and there. That's been an adventure worthy of it's own thread, but it seemed like my stove was either getting acclimated to drier wood, or my stacks are picking up moisture...

So I pulled another good sized sample Thursday afternoon and stuck them in the garage until Sat mid-day.

Just four splits from each cord this time, one from the top, one within 18" of grade. The east end of the east facing splits selected were labeled with an 'E" and so on.

Here is the raw data from my appendiceal module that runs N-S and therefore has an East face and a West face:

FWIW a star (*) entry means less than 7%MC, I don't know how dry...

E *** *** W

E 14-15-14 11-13-15 W

So only one cord left in that module, pretty sure the ones from on top are still too dry to measure, it is the ones closer to grade level that are a leetle bit heavier.

Last edited by a moderator:

The data from the longer set that runs east west and has a north and south face sorted itself in a similar manner:

S*** ***N

S*** ***N

S*** ***N

S*** ***N

S*** ***N

S***

S *-14-11 *-10-12 N

S *-13-15 *-14-11 N

S *-14-15 *-12-13 N

S *-14-15 *-15-14 N

S 11-15-11

S 15-15-15 15-15-14 N

I did ignore two splits that were labeled inconsistently. I can see now they were both off the north facing side...

S*** ***N

S*** ***N

S*** ***N

S*** ***N

S*** ***N

S***

S *-14-11 *-10-12 N

S *-13-15 *-14-11 N

S *-14-15 *-12-13 N

S *-14-15 *-15-14 N

S 11-15-11

S 15-15-15 15-15-14 N

I did ignore two splits that were labeled inconsistently. I can see now they were both off the north facing side...

So looking at the EMC table in post #30 above (@BKVP ):

with current ambient conditions at +27dF and RH at 44-65% depending on who I believe, cord wood top covered outdoors should tend towards about 9.5% MC

wood inside the kilns based on previous observations in similar weather in April and May should be experiencing about +50dF and 25% RH, tending towards 5 or 5.5% MC.

I opened up the side curtains as soon as reached this conclusion.

with current ambient conditions at +27dF and RH at 44-65% depending on who I believe, cord wood top covered outdoors should tend towards about 9.5% MC

wood inside the kilns based on previous observations in similar weather in April and May should be experiencing about +50dF and 25% RH, tending towards 5 or 5.5% MC.

I opened up the side curtains as soon as reached this conclusion.

Last edited by a moderator:

Babaganoosh

Minister of Fire

@bodhran , in nearby portland, or the temp is +35dF, with 51% rh.

with clear skies i would be looking for at least +60fF and rh around 25%, suggesting an emc of about 5% moisture content would be achieved in mid to late feb.

with cloudy skies i would be looking for perhaps +50dF inside kilns with the ends sealed up, rh maybe 35%ish, about 7% emc in mid to late feb

see post #30 above for emc table..

with clear skies i would be looking for at least +60fF and rh around 25%, suggesting an emc of about 5% moisture content would be achieved in mid to late feb.

with cloudy skies i would be looking for perhaps +50dF inside kilns with the ends sealed up, rh maybe 35%ish, about 7% emc in mid to late feb

see post #30 above for emc table..

2fireplacesinSC

Burning Hunk

So the gist of this method is:

Elevate stack

Vapor Impermeable bottom

Variable height side/top vapor barrier

Persistent venting of some amount

Do I have that correct?

Interesting hobby.

Elevate stack

Vapor Impermeable bottom

Variable height side/top vapor barrier

Persistent venting of some amount

Do I have that correct?

Interesting hobby.

So the gist of this method is:

Elevate stack

Vapor Impermeable bottom

Variable height side/top vapor barrier

Persistent venting of some amount

Do I have that correct?

Interesting hobby.

I think the impermeable floor layer is key.

Covered in top, open sides down to fiber saturation point.

From fsp down to finished dryness close the sides, just small vents top and bottom.

bodhran

Burning Hunk

It's currently 25F here with 77% rh.@bodhran , in nearby portland, or the temp is +35dF, with 51% rh.

with clear skies i would be looking for at least +60fF and rh around 25%, suggesting an emc of about 5% moisture content would be achieved in mid to late feb.

with cloudy skies i would be looking for perhaps +50dF inside kilns with the ends sealed up, rh maybe 35%ish, about 7% emc in mid to late feb

see post #30 above for emc table..

Sub freezing temps are a monkey wrench, because of the latent heat of crystalization.It's currently 25F here with 77% rh.

Are you seeing daytime highs above freezing? that will help a lot.

Short version is it will take longer. i spent i think winter of 01/02 in eugene or without a single hard frost.

2fireplacesinSC

Burning Hunk

bodhran

Burning Hunk

Sub freezing temps are a monkey wrench, because of the latent heat of crystalization.

Are you seeing daytime highs above freezing? that will help a lot.

Short version is it will take longer. i spent i think winter of 01/02 in eugene or without a single hard frost.

No, the daytime is mostly below freezing as well. The usual weather pattern here is. Snow, changing to rain, changing to strong cold northwesterly winds. Tomorrow is 37F daytime with .80" of rain, changing to 27F nighttime with flurries and wind. I don't live here for the weather lol.

bodhran

Burning Hunk

No, the daytime is mostly below freezing as well. The usual weather pattern here is. Snow, changing to rain, changing to strong cold northwesterly winds. Tomorrow is 37F daytime with .80" of rain, changing to 27F nighttime with flurries and wind. I don't live here for the weather lol.

Also, it's not unusual to have frost warnings into July month.

Can you give a brief explanation of fiber satura as point? Thanks

In a living tree the cellulose inside each live cell is saturated with water, some if it bound to the celluose chemically (bound water) and some of it just in there.

The live tree also has sap (mostly water) inside all those vertical tubules.

When freshly split and stacked a top covered piece of cordwood will lose the water in the sap tubules in 2 weeks or so.

Once that water is gone, all the remaining water to come out is the free and bound water saturating the cellulose fibers, thus the fiber saturation point.

As the wood continues to dry below the fsp it will begin to change size and shape. Above fsp the size and shape of the split does not change with varying moisture content.

Fsp is generally at or near about 30% for a lot of species.

2fireplacesinSC

Burning Hunk

2fireplacesinSC

Burning Hunk

English BoB

Minister of Fire

So wind, once again is my downfall. In the last 72 hours, give or take, I have gotten 17" of snow on my lot, and then 24 hours of wind, 15mph sustained and gusts to 45mph. I don't have an anemometer on my lot, going by the local weather station for the latter.

Binder clips from OfficeMax and plastic sheeting from Home Depot do OK up to 25-30mph gusts with 5-10mph sustained. I knew I was going to have a mess on my hands.

This morning at sunrise I had this to deal with.

modules 1-4 on the west end...

and modules 5-8 on the east end.

I am going to have to get a big magnet on a stick to find the binder clips currently missing in the snow.

My plan was to consolidate my remaining wood on the east end, recover to keep snow out of it, and use every possible binder clip on the smallest possible sail area.

The half cord on the west end is already bought and paid for as primo grade spruce, FOB module 3. I had to bang every two splits together to get the snow off them and recover so they are still primo grade when the buyer shows up to pick up the rest of the cord he already bought.

Binder clips from OfficeMax and plastic sheeting from Home Depot do OK up to 25-30mph gusts with 5-10mph sustained. I knew I was going to have a mess on my hands.

This morning at sunrise I had this to deal with.

modules 1-4 on the west end...

and modules 5-8 on the east end.

I am going to have to get a big magnet on a stick to find the binder clips currently missing in the snow.

My plan was to consolidate my remaining wood on the east end, recover to keep snow out of it, and use every possible binder clip on the smallest possible sail area.

The half cord on the west end is already bought and paid for as primo grade spruce, FOB module 3. I had to bang every two splits together to get the snow off them and recover so they are still primo grade when the buyer shows up to pick up the rest of the cord he already bought.

Last edited by a moderator:

Got 'er done. I really need some outdoor storage cabinet of some kind to hold my BBQ stuff. The cooking racks for pork ribs stuck in a cordwood kiln is bad enough, my charcoal chimney is full of snow and who knows what I will find when the snow melts.

After:

Looking for a little wind tonight. i guess I'll know in the morning how I did.

What I would "like" to do is build a vapor tight woodshed under my existing second floor deck and ditch three of the modules for $$. I am pretty sure I can harvest two 'crops' of dry cordwood out of these kilns every year. Already have a buyer lined up for numbers 3,4 and 5, don't have permission from SWMBO to build a shed under the deck.

If I dry five, shed those, dry five more and then be donating, burning and selling out of the five still in the kilns I should get to this point in the year with a full shed of dry wood and nearly empty kilns ready to loaded.

Life expectancy of H-D clear plastic sheeting at my house is 10-11 months.

After:

Looking for a little wind tonight. i guess I'll know in the morning how I did.

What I would "like" to do is build a vapor tight woodshed under my existing second floor deck and ditch three of the modules for $$. I am pretty sure I can harvest two 'crops' of dry cordwood out of these kilns every year. Already have a buyer lined up for numbers 3,4 and 5, don't have permission from SWMBO to build a shed under the deck.

If I dry five, shed those, dry five more and then be donating, burning and selling out of the five still in the kilns I should get to this point in the year with a full shed of dry wood and nearly empty kilns ready to loaded.

Life expectancy of H-D clear plastic sheeting at my house is 10-11 months.

Last edited by a moderator:

Similar threads

- Replies

- 14

- Views

- 2K

- Replies

- 21

- Views

- 2K

- Replies

- 9

- Views

- 3K

- Replies

- 6

- Views

- 739