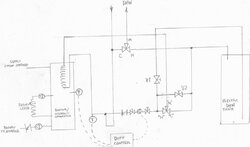

Buffer tank has tankless coil in the top of it, nominally a '7 GPM' unit that supplies continuous hot water if top of buffer tank is maintained above 140 degF or so.

During heating season valve V1 is closed and V2 is open. Heated water flows though tankless coil, into diverting valve. Presumably water is hot so it is diverted out the "C" port, up and over to the mixing valve, and is mixed out to the demand. Differential temperature controller and the bronze recirc pump are used during heating season to keep the whole tankless coil circuit hot.

During non-heating season, valve V1 is open and V2 is closed. If water arriving at diverting valve is hot enough it is diverted directly to the DHW load. Otherwise not-so-hot water is diverted to the bottom of the electric DHW tank. Electric tank brings the water up to a usable temperature. Whenever the buffer tank is hot enough the DHW tank will be filled from the top with hot water by the recirc pump.

During heating season valve V1 is closed and V2 is open. Heated water flows though tankless coil, into diverting valve. Presumably water is hot so it is diverted out the "C" port, up and over to the mixing valve, and is mixed out to the demand. Differential temperature controller and the bronze recirc pump are used during heating season to keep the whole tankless coil circuit hot.

During non-heating season, valve V1 is open and V2 is closed. If water arriving at diverting valve is hot enough it is diverted directly to the DHW load. Otherwise not-so-hot water is diverted to the bottom of the electric DHW tank. Electric tank brings the water up to a usable temperature. Whenever the buffer tank is hot enough the DHW tank will be filled from the top with hot water by the recirc pump.