- Oct 7, 2013

- 17

Thought I'd appeal to the collected wisdom here on our plans for the chimneys / wood heating which we're installing in a house we're reconstructing. The house is two full floors of 1600 sq. ft. each (40 x 40' square), with a full basement and a 300 sq.ft. cupola at top. (No, we didn't want a house this large, but it came with the farm we DID want.  )

)

We are designing it so that the first floor will serve as the primary space for the two of us to live, with the second floor being used for guest bedrooms, office/work/hobby etc. We are planning on using the PE Summit to heat the first floor for the immediate future. We are building two separate masonry chimneys of 16x16 concrete block, one for the Summit and one for possible future use with a wood furnace in the basement. The house is currently ducted and we thought we could use a wood furnace for when the house is fully filed with friends and family. We are starting on the block work this week, with one stainless steel liner to be put in for the first floor. Both chimneys will be brought into the insulated building envelope during construction, but will still remain on an outer wall.

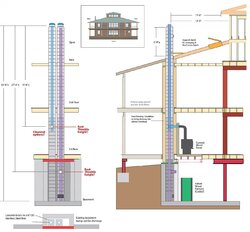

I've attached a fairly detailed drawing that shows placement and primary dimensions for the chimneys, which sit on a bump-out in the basement floor. In addition to the required clearances to combustibles, I believe everything as designed should meet or exceed code. We do have some things up in air at this point a) best height for thimbles b) how close should we place the masonry blocks to each other c) clean out options for the first floor stove and d) hearth design.

Any thoughts or suggestions on this approach?

)

) We are designing it so that the first floor will serve as the primary space for the two of us to live, with the second floor being used for guest bedrooms, office/work/hobby etc. We are planning on using the PE Summit to heat the first floor for the immediate future. We are building two separate masonry chimneys of 16x16 concrete block, one for the Summit and one for possible future use with a wood furnace in the basement. The house is currently ducted and we thought we could use a wood furnace for when the house is fully filed with friends and family. We are starting on the block work this week, with one stainless steel liner to be put in for the first floor. Both chimneys will be brought into the insulated building envelope during construction, but will still remain on an outer wall.

I've attached a fairly detailed drawing that shows placement and primary dimensions for the chimneys, which sit on a bump-out in the basement floor. In addition to the required clearances to combustibles, I believe everything as designed should meet or exceed code. We do have some things up in air at this point a) best height for thimbles b) how close should we place the masonry blocks to each other c) clean out options for the first floor stove and d) hearth design.

Any thoughts or suggestions on this approach?