Clearly I'm searching for the wrong terms, or maybe just everyone already knows this, but:

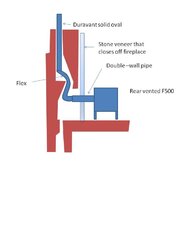

I will have a Jotul F500, rear-vented through wall using double-wall pipe, to 5' flex SS. to 20' of solid insulated oval duravent.

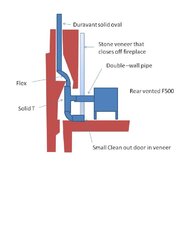

I could get brushes down the chimney - how do I get to the crud that I clean off, what about cleaning the double-wall pipe and small section of flex?

Thanks.

I will have a Jotul F500, rear-vented through wall using double-wall pipe, to 5' flex SS. to 20' of solid insulated oval duravent.

I could get brushes down the chimney - how do I get to the crud that I clean off, what about cleaning the double-wall pipe and small section of flex?

Thanks.

When are you getting the stove & why the oval run, why not a round double wall ss?

When are you getting the stove & why the oval run, why not a round double wall ss?