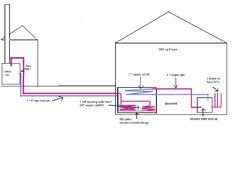

It would work, (I think) though it probably isn't the way I'd do it..

1. Tank size - 500g seems a bit small - especially for a 3K²' house... Might be OK depending on your heat loss calcs (which I didn't see...) but might not give you that much time running on storage.

500 gallon tank is about all I have room for. I would be happy if I could run off the storage for 4-5 hours. I am looking for a situation where my Seton will run for perhaps 2 hours and then idle for 3-4 hours. I would add wood 2X/day like I do now. I want to have some extended burn times to eliminate/minimize creosote builup.

2. Why two separate heating systems? If both systems are pressured, why not tie them together, so that you would only need ONE HX coil in the tank, and allow you to directly send heat from the wood boiler to the house loads w/o having to cycle through the storage tank (which would involve 2HX penalties, and thus be less efficient)

OK yes, sounds good, how do I do that?

3. As drawn, putting the charge coil in the bottom and the draw coil on top will do strange things to your stratification.... If you do want to do separate coils, I'd put them next to each other, each going top to bottom in the tank, with the charge coil flowing top to bottom, and the discharge coil flowing bottom to top - this will give the best stratification.

I was wondering about that when I drew it. My thought was that the hotter water would be near the top of the tank, but I see your idea would be better, but I still like the other idea of having only 1 HX coil.

4. How long is the boiler - house loop? How much heat will you be trying to cycle through it? - is 1.25" PEX going to be enough to carry the required number of BTUs/hr with reasonable pump sizing? (Have you done the pump sizing calculations from the Taco paper I link to in the "tidbits" sticky?)

My boiler is about 50 feet from the inside propane boiler. I have no idea on the required BTU's. I have a Taco 0011 on the Seton now, seems to be moving the water pretty good. Haven't checked out the Taco paper.

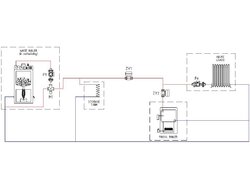

As a rough idea, what I would probably do with the diagram you gave, is tie the two systems together, with one coil in a larger tank, and stick a 3-way valve on the pipes going into the tank set up so as to allow the flow from the wood boiler to feed the house and / or the storage depending on the exact amount of call coming from the house loads. I'd put a flow check in the barn / storage loop, and an extra pump (smaller since it will have a shorter distance to pump) in the storage / house loop to reverse the flow direction to discharge the storage into the house when the boiler is out. I would connect the backup boiler to the house loops in parallel so that the storage would not feed through it...

You really lost me here, I have no idea what this would look like or how it would work. I know basic plumbing and can do all my own work, but don't understand what you mean here.?

Gooserider