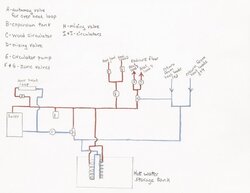

First, thank you all for the info that you post on here. It has been very informative. My husband and I have finally decided to replace our 30 year old tarm with a gasification boiler. We are getting a Biomass 80 that should be delivered in a week or two. We had planned on just pulling out the Tarm and replacing it with the Biomass, but realized that some things aren't plumbed right and the piping is too small for the new boiler. I have attached a basic schematic just as a starting point for what we have come up with for a piping layout. We have a friend that is a plumbing and heating guy but hasn't dealt with wood boilers that much so he can't help a lot with the design but can help with the install if needed. I haven't included in the design check valves or places to fill and drain the system or purge the air. I just wanted to get a basic idea first if what we were thinking was even on the right track. Pressurized storage is out and we have the materials to build a storage tank. This will be going in the basement as we already have some of the plumbing that won't be changed such as the radiant heat zones or how they are plumbed from the manifold out. (At least I hope not.) Any suggestions for a different way to do this would be appreciated or if there are any glaring errors that we don't know about. Thank you all.

Shelly

Shelly

. But since he purchased most of it for the cost of one circ pump I didn't complain this time. We have no oil back up as we don't go anywhere in the winter and if in case of emergency if we actually went somewhere, various family members live down the road and would come stoke the boiler if necessary. I'm trying to talk him into adding the necessary tees and etc so that an oil boiler could be plumbed in at some future time if needed. He plans on being here for a long time or some other family member wants to buy the house, so doesn't see the need for one. The house has been in the family since it was built, over a 150 years ago. The radiant isn't the only heat in the house so at least we won't freeze when it actually comes time to disconnect the Tarm.

. But since he purchased most of it for the cost of one circ pump I didn't complain this time. We have no oil back up as we don't go anywhere in the winter and if in case of emergency if we actually went somewhere, various family members live down the road and would come stoke the boiler if necessary. I'm trying to talk him into adding the necessary tees and etc so that an oil boiler could be plumbed in at some future time if needed. He plans on being here for a long time or some other family member wants to buy the house, so doesn't see the need for one. The house has been in the family since it was built, over a 150 years ago. The radiant isn't the only heat in the house so at least we won't freeze when it actually comes time to disconnect the Tarm.