Thimble insulated enough?

- Thread starter bkatzman

- Start date

-

Active since 1995, Hearth.com is THE place on the internet for free information and advice about wood stoves, pellet stoves and other energy saving equipment.

We strive to provide opinions, articles, discussions and history related to Hearth Products and in a more general sense, energy issues.

We promote the EFFICIENT, RESPONSIBLE, CLEAN and SAFE use of all fuels, whether renewable or fossil.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Status

- Not open for further replies.

Wood Heat Stoves said:9"??

where did you get that number?

https://www.hearth.com/econtent/index.php/articles/passing_a_chimney

As I said, from the link earlier. The article states the info is from NPFA, and Craig wrote it, I assume the info is good?

I guess I wrote my response earlier in a hurry also, its not 9" air space all the way, you mortar the class A pipe in, and then as it passes through the combustible wall you need 9". It explained in the article.

-----------

So now that you have thought about replacing the thimble, what about the original idea? A UL Listed wall pass-through.

Page 7, Fig. 12: http://duravent.com/docs/instruct/L253_Oct03_Omni.pdf

Directions below state you only need a 14.5" diameter hole in the combustible wall for this pass through to work. Seems like that should work in your case?

There is some more instructions in here also.

http://www.duravent.com/?page=instruct/dliner/403/L403.php

With a ICC wall pass through 6" pipe you need 12"X12" framing.And a cost of about $180.00.Just put one in last week.And if the pipe will pass through clay thimble I would not remove it.

Hey Daryl,

I would love to have that option, but unfortunately I only have 7" clearance from the bottom of the pipe to the 2x4 framing that is behind a brick wall (that runs behind the wood stove), so I am looking into "other" options...

The code inspector is coming today for a pre-building inspection, so hopefully he can shed some light on what I can/cannot do (for code at least)...

I will let you know what he says.

Thanks for everyone's input. It has helped me become a little less of a noob when it comes to this stuff!

Bryce

I would love to have that option, but unfortunately I only have 7" clearance from the bottom of the pipe to the 2x4 framing that is behind a brick wall (that runs behind the wood stove), so I am looking into "other" options...

The code inspector is coming today for a pre-building inspection, so hopefully he can shed some light on what I can/cannot do (for code at least)...

I will let you know what he says.

Thanks for everyone's input. It has helped me become a little less of a noob when it comes to this stuff!

Bryce

So of course I am a crossroads here. My code inspector said I would be fine without having to replace the thimble, so here's my plan. I know some of you wouldn't do this in your home, but hopefully you will comment either way!

From the Cawley-Lemay I will use a single wall elbow, 4 feet of single wall vertical (there is a brick wall behind the stove/pipe). Once above the brick I will use a single wall elbow and then single wall into the thimble. I will use 8" either Metalbestos or Duratech (what are people's preference?) double wall (about 18" long) to cover both the thimble and single wall. So the double wall will cover both the thimble and single wall at the point where combustibles are are about 7 inches away, which makes me feel very, but not extremely safe. I will also cover the combustibles with stone or slate, just to be sure....

Like I said many might/ might not agree with this, let me know either way. It sucks that this whole problem revolves around only the bottom part of the thimble being only 7" from a 2/4 (that runs behind the brick wall).

As always THANKS everybody!

Bryce

From the Cawley-Lemay I will use a single wall elbow, 4 feet of single wall vertical (there is a brick wall behind the stove/pipe). Once above the brick I will use a single wall elbow and then single wall into the thimble. I will use 8" either Metalbestos or Duratech (what are people's preference?) double wall (about 18" long) to cover both the thimble and single wall. So the double wall will cover both the thimble and single wall at the point where combustibles are are about 7 inches away, which makes me feel very, but not extremely safe. I will also cover the combustibles with stone or slate, just to be sure....

Like I said many might/ might not agree with this, let me know either way. It sucks that this whole problem revolves around only the bottom part of the thimble being only 7" from a 2/4 (that runs behind the brick wall).

As always THANKS everybody!

Bryce

Ok.... the part Daryl mentioned only needs a 12x12 box out, centered on the hole. If you have 7" from the bottom of the thimble to the framing, how would that not work?

hEY jtp

Thanks for keeping up with this one.

If I made a 12x12" box o' bricks around the pipe (which is 7.5 wide) that would only give me a clearance of 2.25 inches on each side between the pipe and wood (combustibles). How is that better than using Metalbestos or Duratech (which can reduce clearance needs drastically all the way down to 6") as a "cuff"?

Like I said thanks for checking-in I really appreciate you helping me with this

Bryce

Thanks for keeping up with this one.

If I made a 12x12" box o' bricks around the pipe (which is 7.5 wide) that would only give me a clearance of 2.25 inches on each side between the pipe and wood (combustibles). How is that better than using Metalbestos or Duratech (which can reduce clearance needs drastically all the way down to 6") as a "cuff"?

Like I said thanks for checking-in I really appreciate you helping me with this

Bryce

Bummer the infamous "How to Pass a Chimney through a Wall" article says:

"This installation is known as a “wall patch” which entails 12” of solid masonry around all sides of the crock." So it is not saying that the box needs to be 12x12 but the thimble needs clearance of 12" on all sides...

"This installation is known as a “wall patch” which entails 12” of solid masonry around all sides of the crock." So it is not saying that the box needs to be 12x12 but the thimble needs clearance of 12" on all sides...

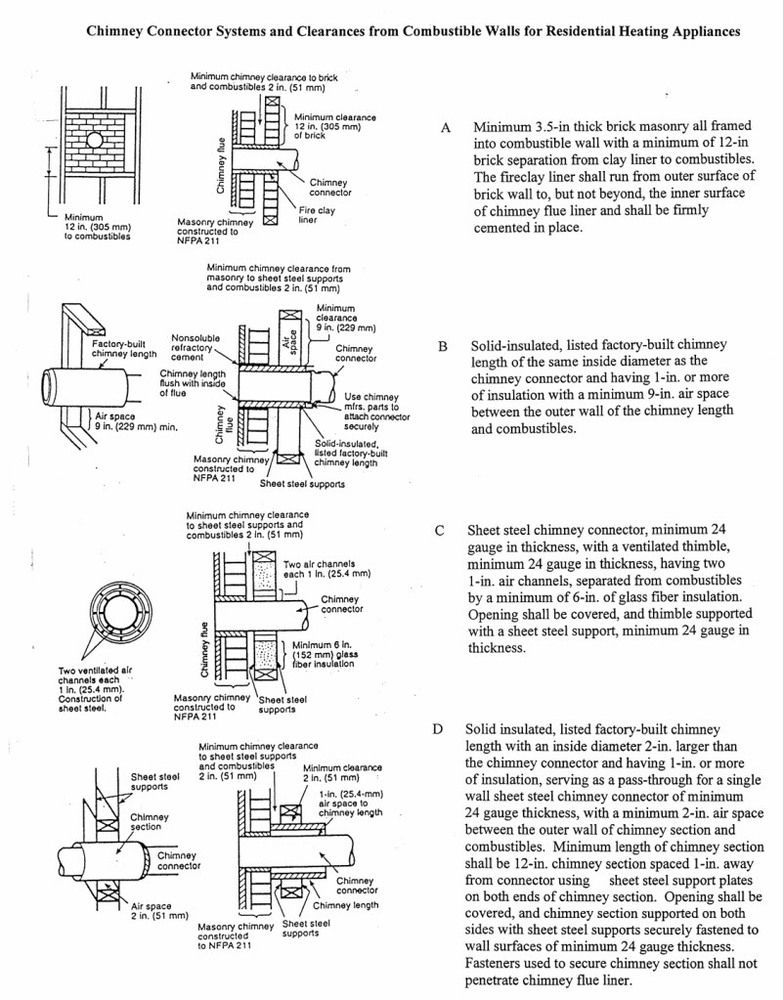

Here's what the england company recommends these directions are nfpa compliant so they should be good for most all stoves.

pen

pen

Yup.. Don't have the 12 inches below the pipe...

Thanks for the verification...

Now to choose between Duratech and Metalbestos...

If the outside width of the thimble is 7.5 I should be be buying an 8" double-walled correct (so that the old thimble will fit inside)??

Thanks for the verification...

Now to choose between Duratech and Metalbestos...

If the outside width of the thimble is 7.5 I should be be buying an 8" double-walled correct (so that the old thimble will fit inside)??

The DuraPlus with it's beefy 2" clearance need seems like the right choice for me to cuff over the clay thimble and single wall..

You are not understanding my point... I am not talking about a clay thimble or a class A pipe used as a thimble. I am talking about a specilly designed wall pass through. The one Daryl mentioned needs a 12x12 hole in the combustible wall. that means a 12x12 box made from studs. Thats all the clearance you need. 12" x 12". Anything outside of that does not matter.

You previously stated you have 7" from the bottm of the thimble to a 2x4. This would put the center at least 10" away. If you made a 12x12 box out in the combustible wall centered on the existing hole, it should land you around 5" above this problematic 2x4.

I am failing to see where there is a problem here? Am I misunderstanding something, or are you?

You previously stated you have 7" from the bottm of the thimble to a 2x4. This would put the center at least 10" away. If you made a 12x12 box out in the combustible wall centered on the existing hole, it should land you around 5" above this problematic 2x4.

I am failing to see where there is a problem here? Am I misunderstanding something, or are you?

Sorry JTP. I am very slow when it comes to mechanical stuff.

I see what you're saying. Leave the thimble where it is and make a 12 inch box o' bricks centered around the thimble. It would give me the clearance I need.

However although I am new at this I would think that using a Duraplus or Metalbestos (which would be slightly cheaper and more importantly, involve zero labor) would be as safe?

Thanks for clearing me up on all this stuff.

Bryce

I see what you're saying. Leave the thimble where it is and make a 12 inch box o' bricks centered around the thimble. It would give me the clearance I need.

However although I am new at this I would think that using a Duraplus or Metalbestos (which would be slightly cheaper and more importantly, involve zero labor) would be as safe?

Thanks for clearing me up on all this stuff.

Bryce

Not bricks...... its a special product made out of metal and insulation, purpose built, WALL PASS THROUGH

http://www.dalsinmfg.com/insulflue.html

http://www.fireplacesnow.com/viewPrd.asp?idproduct=51320

You box out with studs and inserts this into the combustible wall.

These products are UL tested and listed for the exact purpose you need them for, and as far as I can tell would meet clearances in your situation.

The class A pipe is not as safe because it is not tested for this purpose. NFPA specs state if you mortar in a piece of class A you then need 9" of AIR SPACE clearance around it as it passes through a combustible wall. This is because where it is mortared in, will trap heat, so this negates the normal 2" clearance rating for the pipe.

I really don't know how else to explain it...

http://www.dalsinmfg.com/insulflue.html

http://www.fireplacesnow.com/viewPrd.asp?idproduct=51320

You box out with studs and inserts this into the combustible wall.

These products are UL tested and listed for the exact purpose you need them for, and as far as I can tell would meet clearances in your situation.

The class A pipe is not as safe because it is not tested for this purpose. NFPA specs state if you mortar in a piece of class A you then need 9" of AIR SPACE clearance around it as it passes through a combustible wall. This is because where it is mortared in, will trap heat, so this negates the normal 2" clearance rating for the pipe.

I really don't know how else to explain it...

JTP,

Your suggestion/insistance has not fallen on deaf ears. I looked at the Insulflu product, and although it would work like a charm it is simply out of my price range and skill level (the problem is I don't have anything to easily securely attach the frame to).

So here is what I have done:

Removed all combustibles with 18 inches of the thimble (except for the bottom, which I have said is 7 inches to combustibles, but I can make 9 if I cut into the 2x4 )

I will cut the 4 inches of thimble, so that the "hole" is flush with the chimney.

So the only thing I will have to deal with is the single wall clearance, which is 18", and as I had said above the only place where there is a problem is the bottom (which will be 9" clearance).

I will be getting a heat shield which needs between 6" and 9" (I have seen both numbers) clearance.

So in essence I will get the thimble (which is in a masonry chimney) out of the equation and focus on getting the stove pipe clearance taken care of.

Thanks a lot JTP, I really appreciate your professional opinion (which is very hard to come by these days either for free or for $$$) and your patience with me. I can fix computers but I am not what you'd call "good with my hands" (hopefully my wife disagrees

Bryce

Your suggestion/insistance has not fallen on deaf ears. I looked at the Insulflu product, and although it would work like a charm it is simply out of my price range and skill level (the problem is I don't have anything to easily securely attach the frame to).

So here is what I have done:

Removed all combustibles with 18 inches of the thimble (except for the bottom, which I have said is 7 inches to combustibles, but I can make 9 if I cut into the 2x4 )

I will cut the 4 inches of thimble, so that the "hole" is flush with the chimney.

So the only thing I will have to deal with is the single wall clearance, which is 18", and as I had said above the only place where there is a problem is the bottom (which will be 9" clearance).

I will be getting a heat shield which needs between 6" and 9" (I have seen both numbers) clearance.

So in essence I will get the thimble (which is in a masonry chimney) out of the equation and focus on getting the stove pipe clearance taken care of.

Thanks a lot JTP, I really appreciate your professional opinion (which is very hard to come by these days either for free or for $$$) and your patience with me. I can fix computers but I am not what you'd call "good with my hands" (hopefully my wife disagrees

Bryce

I only have the question of single wall....? why do you near clearance to that. It cannot pass through the wall, nor should it be anywhere near it. Use double wall pipe anyway... much better.

BTW, I fix computers too

BTW, I fix computers too

I removed all the wood within 18 inches of the thimble, (except the 2x4 which is 7" under the thimble or stove pipe) so it is no longer passing through a wall.

I definitely agree that using double wall from the stove to the thimble is a better bet!

Thanks!

I definitely agree that using double wall from the stove to the thimble is a better bet!

Thanks!

- Status

- Not open for further replies.

Similar threads

- Replies

- 0

- Views

- 1K

- Replies

- 3

- Views

- 899

- Replies

- 27

- Views

- 2K

- Replies

- 2

- Views

- 553