First fire of the year, first post of the year - must be Fall. This year, the first fire was also the first since I upgraded my controls to our latest controller - wireless sensors and all. Aside from a few typos everything worked, though I'm sure that someone will be quick to point out that the link in my sig is still messed up.

Still plenty of projects, wood to stack, and posts to catch up on. Happy wood burning season to all!

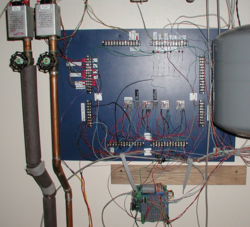

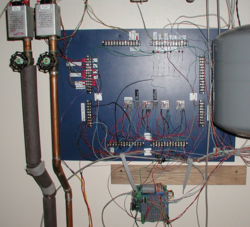

Thought I'd also do a little historical retrospective. Way back in the beginning, I built a home-brew control system that consisted of a bunch of relays and a little embedded computer. It didn't look like much, but it managed the heat sources and heat loads between my wood boiler, oil boiler, and heat storage.

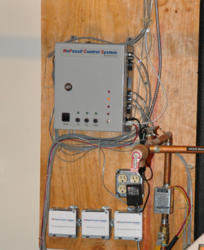

Eventually I started making a semi-commercial version called the 'NoFossil Control System (NFCS). Several folks here have one. After several years I upgraded my own system to use the NFCS:

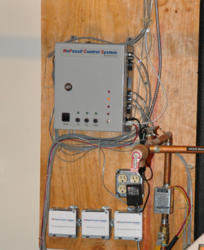

A couple years ago, a friend and I started an actual business making a commercial/industrial version. Last week I finally upgraded my home system to use our latest product:

The little round black unit toward the right is an alarm buzzer. The 4" utility boxes along the bottom hold the variable speed drive electronics for the wood boiler circ, the wood boiler recirc, and the wood boiler blower.

Still plenty of projects, wood to stack, and posts to catch up on. Happy wood burning season to all!

Thought I'd also do a little historical retrospective. Way back in the beginning, I built a home-brew control system that consisted of a bunch of relays and a little embedded computer. It didn't look like much, but it managed the heat sources and heat loads between my wood boiler, oil boiler, and heat storage.

Eventually I started making a semi-commercial version called the 'NoFossil Control System (NFCS). Several folks here have one. After several years I upgraded my own system to use the NFCS:

A couple years ago, a friend and I started an actual business making a commercial/industrial version. Last week I finally upgraded my home system to use our latest product:

The little round black unit toward the right is an alarm buzzer. The 4" utility boxes along the bottom hold the variable speed drive electronics for the wood boiler circ, the wood boiler recirc, and the wood boiler blower.