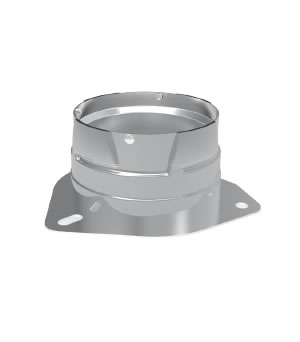

Hello. I'm currently working on a new pellet stove installation in my home. I was test fitting some parts from Duravent's Pellet Vent line (not pro, the normal less expensive type with rope gaskets). Some of the parts slip nicely onto the others and twist lock smoothly. Some don't. They slip on much harder and I cant get them to twist reasonable force. Should the parts twist easy or are they supposed to be so tight they need strap wrench? Just seems like that kind of force might damage the pipe. For details, I'm running 4" double wall pellet vent into a masonry chimney that I'm relining. I noticed the adjustable 12" sections and appliance adapter T (3" to 4") have male ends that seem to be causing the problems. If I hook the 90° elbow to male end of the non-adjustable 12" and 24" sections, it's a smooth connection with an effortless twist. If I take the same 90° elbow, the same 12" non adjustable and try to put it on the male ends of my two adjustable 12" sections, they need to be pushed hard and the connecting female ends cant be twisted on. Putting the elbow and straight non-adjustable sections on the cleanout T seem to yield the same kind of stuck results as the adjustable sections. Either I'm doing this wrong or the big box duravent brand has tolerance quality issues. I've been putting this project together for months and its taken a long time to source the materials due to supply shortages and balooning material costs. Sending the pipes back to switch product lines would stink pretty bad right now. I do know all about the Duravent Pro line and all the pros. I just don't know how they feel when working with it compared to this big box Duravent line I'm using. I can't find a real answer on this and Duratech tech support is not as fast as this forum! People are busy and I understand that. Could anyone help with advice? Thanks in advance.

Pellet Vent parts not twist locking/getting stuck

- Thread starter TeamCav

- Start date

-

Active since 1995, Hearth.com is THE place on the internet for free information and advice about wood stoves, pellet stoves and other energy saving equipment.

We strive to provide opinions, articles, discussions and history related to Hearth Products and in a more general sense, energy issues.

We promote the EFFICIENT, RESPONSIBLE, CLEAN and SAFE use of all fuels, whether renewable or fossil.

![[Hearth.com] Pellet Vent parts not twist locking/getting stuck [Hearth.com] Pellet Vent parts not twist locking/getting stuck](https://www.hearth.com/talk/data/attachments/308/308325-3cd0e13b0fc735daf8856ddada2f7f0d.jpg?hash=EBnNdSENBh)