Two new BK Ashford 30's in da'house

- Thread starter Ashful

- Start date

-

Active since 1995, Hearth.com is THE place on the internet for free information and advice about wood stoves, pellet stoves and other energy saving equipment.

We strive to provide opinions, articles, discussions and history related to Hearth Products and in a more general sense, energy issues.

We promote the EFFICIENT, RESPONSIBLE, CLEAN and SAFE use of all fuels, whether renewable or fossil.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Status

- Not open for further replies.

It is boring.

On the plus side, boring means no surprises and no babysitting. I was hoping to get something different, but SWMBO wants another BK.

On the plus side, boring means no surprises and no babysitting. I was hoping to get something different, but SWMBO wants another BK.

I remember running my new BK for the first time. I kept walking over and checking the thermometer to see if it was still burning. With the new (overactive) cat the thermometer would often read at or over 600* stove top for hours before slowly settling in. Still amazes me to feel so much heat from a black fire box.

Hell, I'm excited just reading about YOUR first fire!

Hell, I'm excited just reading about YOUR first fire!

Woody Stover

Minister of Fire

Try to keep up.I'm sorry to say... yes. I did not specify a steelcat, but I guess that's what they're shipping now?

I had experimented with steelcats in my Jotuls, and found they don't hold up very well at all, to the high temps cats run in those stoves. Have heard many other Jotul and VC cat stove owners had the same complaint, and like many of them, I ended up switching back to ceramic. I'm hoping they hold up okay in the BK, but I think I'd have been more comfortable with a ceramic cat.

These are DuraFoil cats, like the Ws stoves...they will hold up fine.

These are DuraFoil cats, like the Ws stoves...they will hold up fine.You may be able to dig up the offset table online, for the brand of chimney you are using.Looking for a combination of elbows (30's or 45's) that will give me a 9" offset, for the other.

So, I call Rockford Chimney Supply, and wait on the phone while the guy on the other end of the line goes back to the shop and checks his various elbows. He says that two 45's give him exactly 9" offset, so I order them. Received, and I'm seeing 5" offset. One of us does not know how to measure...Looking for a combination of elbows (30's or 45's) that will give me a 9" offset, for the other.

Ideas? I could throw a segment of straight between the elbows, to extend, but was hoping to find a combo of two elbows that would just get me close to 9" without any extension. I gave away all of my good 6" straight pipe last year, and local suppliers only seem to stock the thin cheap stuff that I won't use.

Last edited by a moderator:

Highbeam

Minister of Fire

He probably eyeballed the total measurement which look to be almost 10". Looks like you'll need that short band of single wall.

Yeah, frustrating... but I have to admit this is very nice heavy single wall, with very clean welded seams and crimps. Even pre-drilled for screws! Definitely nicer quality than the garbage they sell at Lowes or Ace.The reason I only used those people one time. Sponsor or not.

I think it depends on how much chimney follows. We have no draft issues on a straight up 20ft chimney, but if this was a 12ft chimney I might have placed them at the ceiling to mitigate the effect of the offset.

I have a 30 degree elbow right off the collar then a four foot run to another 30. My thinking was to achieve proper clearance this would be better than two 45's further up.I can't say if it works better ofcourse without trying something different but it does fine as is and looks clean.

I'm interested to see if those early elbows have a negative effect on the draft. On the Princess they don't want an elbow before 36 inches. Haven't read much on the Ashford, I'd imagine it's similar.

Elbows did have an adverse effect on my Ashford. I had smoke spillage when the door was opened and somewhat sluggish draft. I actually moved my chimney over to eliminate the elbows. It did much better. I have about 14' from floor to the chimney cap.

I was going to try to put these dual 45's up at the block off plate, about 6' above the stove, if my clearances will allow for it. Then again, this 29' chimney surely sucks harder than BK spec's, so having the dual 45's right on the stove collar would probably not be a bad thing, on this one.

I could not find any offset tables on the Rockford site, but yeah... tan(45) = sqrt(2), so 6" should get me pretty close. If I call and order a 6" pipe, is that 6" effective length (i.e. 8" physical), or do I have to measure their crimped connector length and include in pipe length? Don't trust these guys to know what they have anymore, and would hate to use the tinfoil-thick riveted crap I can find locally. The Rockford pipe is very heavy, with welded seams... nice stuff.

I could not find any offset tables on the Rockford site, but yeah... tan(45) = sqrt(2), so 6" should get me pretty close. If I call and order a 6" pipe, is that 6" effective length (i.e. 8" physical), or do I have to measure their crimped connector length and include in pipe length? Don't trust these guys to know what they have anymore, and would hate to use the tinfoil-thick riveted crap I can find locally. The Rockford pipe is very heavy, with welded seams... nice stuff.

mellow

Resident Stove Connoisseur

I would call rockford and let the manager know his guys were wrong, I am quite sure they would be willing to swap out parts to make it right, I have only had good experiences with them, but then again I didn't ask detailed questions.

BKVP

Minister of Fire

I would see if you can get it in double wall...I was going to try to put these dual 45's up at the block off plate, about 6' above the stove, if my clearances will allow for it. Then again, this 29' chimney surely sucks harder than BK spec's, so having the dual 45's right on the stove collar would probably not be a bad thing, on this one.

I could not find any offset tables on the Rockford site, but yeah... tan(45) = sqrt(2), so 6" should get me pretty close. If I call and order a 6" pipe, is that 6" effective length (i.e. 8" physical), or do I have to measure their crimped connector length and include in pipe length? Don't trust these guys to know what they have anymore, and would hate to use the tinfoil-thick riveted crap I can find locally. The Rockford pipe is very heavy, with welded seams... nice stuff.

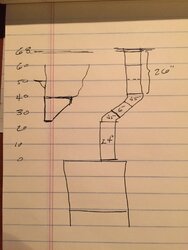

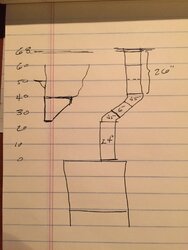

Just did some measuring. My CTC (if you want to call a timber lintel "combustible") is 17 inches, from existing vertical telescoping section to closest spot on lintel, with pipe connected directly to liner at blockoff plate. I need to jog that pipe 9" forward to mate up to the BK, and if I follow the initial plan of putting the jog up top at blockoff plate, I'll be down to 8" from lintel. Probably getting a little too close.

So, I could come up from stove with 24" straight pipe, then the elbows for the jog, followed by another 26" of height in a telescoping pipe. Shown below, this would keep me around 17" CTC.

If I went to double-wall, I guess I'd have more options. I'd lose my beloved surface thermometer, which I've been using the last several years on the single wall (very handy), but that's not a deal killer.

Thoughts?

So, I could come up from stove with 24" straight pipe, then the elbows for the jog, followed by another 26" of height in a telescoping pipe. Shown below, this would keep me around 17" CTC.

If I went to double-wall, I guess I'd have more options. I'd lose my beloved surface thermometer, which I've been using the last several years on the single wall (very handy), but that's not a deal killer.

Thoughts?

BKVP

Minister of Fire

Keep the stack warm...Just did some measuring. My CTC (if you want to call a timber lintel "combustible") is 17 inches, from existing vertical telescoping section to closest spot on lintel, with pipe connected directly to liner at blockoff plate. I need to jog that pipe 9" forward to mate up to the BK, and if I follow the initial plan of putting the jog up top at blockoff plate, I'll be down to 8" from lintel. Probably getting a little too close.

So, I could come up from stove with 24" straight pipe, then the elbows for the jog, followed by another 26" of height in a telescoping pipe. Shown below, this would keep me around 17" CTC.

If I went to double-wall, I guess I'd have more options. I'd lose my beloved surface thermometer, which I've been using the last several years on the single wall (very handy), but that's not a deal killer.

Thoughts?

View attachment 158637

Highbeam

Minister of Fire

Double wall gets you better draft which is always welcome on these low flue temp stoves. I recall that your chimney is tall and drafts well with regular stoves but the bk needs more.

Other than sentiment, the probe meter is superior in every way and can only be used on double wall. I see that as another benefit of going to double wall.

Other than sentiment, the probe meter is superior in every way and can only be used on double wall. I see that as another benefit of going to double wall.

- Status

- Not open for further replies.

Similar threads

- Replies

- 20

- Views

- 679

- Replies

- 8

- Views

- 1K

- Replies

- 10

- Views

- 806

- Replies

- 4

- Views

- 883