I just finished a new heating system and went with a New Yorker 130 wood boiler with a wall-mount propane boiler as a secondary boiler. I run both Radient heat and baseboard off this set-up as I have existing structure and a new addition. My problem is that the wood boiler gets the water in the boiler up to temperature and then dumps it into the heating loop, and within a minute or two, the returning water from the house cools the boiler down and then starts the cycle of the boiler needing to get the returning 20 gallons of water back up to temperature. This can take 7-9 minutes based on the fire. By that time, the hot water that is circulating in the house is cold again. When sizing my system, the heating contractor said I needed 80,000 BTU's, and we went with a 130 to allow for overage. Therefore, it doesn't appear that I am undersized. The propane works well, but it uses propane which is my problem there! I would like to have a heating system that doesn't burn so much propane through the winter months. I was hoping this wood boiler would be able to stand alone 80-90% of the time, but it is just not doing it. I thought about even getting a different boiler such as a gasification boiler or coal that may be able to have a shorter recoup time. I could really use some help here as I have had my heating guy and a field rep from the distributor come and look at my system. The end result is both of them shaking their heads and walking away with no great ideas. Thoughts? Ideas?

Wood boiler not enough?

- Thread starter cschwinn

- Start date

-

Active since 1995, Hearth.com is THE place on the internet for free information and advice about wood stoves, pellet stoves and other energy saving equipment.

We strive to provide opinions, articles, discussions and history related to Hearth Products and in a more general sense, energy issues.

We promote the EFFICIENT, RESPONSIBLE, CLEAN and SAFE use of all fuels, whether renewable or fossil.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Status

- Not open for further replies.

Willman

Minister of Fire

Hows you wood supply? Good species and MC?

Are you running return temperature protection? Primary combustion boilers don't get as hot as gassifiers, but you should be able to make it work. Others will chime in with their suggestions.

Will

Are you running return temperature protection? Primary combustion boilers don't get as hot as gassifiers, but you should be able to make it work. Others will chime in with their suggestions.

Will

Hunderliggur

Minister of Fire

If you have a return protection loop (I use a 140F Danfoss Valve), the boiler will work up to a steady state. My gassification boiler runs about a 20F delta T while charging a storage tank. You don't have storage, but the idea is the same. When the boiler is starting up and the house (or heating loop) is warming up, you will have a lower flow rate to the house as the return temp builds. As the return temp builds, the flow to the house will be greater. A wood boiler s not an "instant on" device like a propane (or electric) boiler, but it can be less expensive to operate. You could use the boiler to "pre heat" the propane. Until theboiler reaches a good steady stat, the propane will add heat to make up to the usable temp. THis will get the return temps up quicker and then the propane will not have to fire.

Hope this helps.

Hope this helps.

Interesting, I have been trying to find ways to slow down the returning water - possibly through Actuators in my Radiant loop manifold etc. This looks like a viable and less complicated alternative. One question I have is where it should be located. I have a bypass valve (manual valve) that I placed in the line right above the boiler with it staying at 1/4 open. This keeps the returning water from what I have termed "tanking" the boiler where the return temp drops the boiler temp 20+ degrees. Then it takes a day's age to recover. It helps slightly, but still is nowhere near what I need. This valve looks like this may be another good option and would probably solve or reduce my creosote issue - which can be substantial.

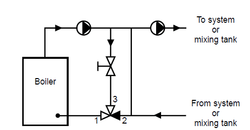

Placement is a question. I have so much water in the system, it takes so long for the boiler to affect the return water temp from the radiant (and to a lesser degree of the baseboard) - if at all. I could see my boiler running for hours before it is going full speed to the heating loops. I assume I would want it on the return line as in the attached diagram recommended by the manufacturer as close to the other loop as possible?

Placement is a question. I have so much water in the system, it takes so long for the boiler to affect the return water temp from the radiant (and to a lesser degree of the baseboard) - if at all. I could see my boiler running for hours before it is going full speed to the heating loops. I assume I would want it on the return line as in the attached diagram recommended by the manufacturer as close to the other loop as possible?

Attachments

Fred61

Minister of Fire

NE Wonder said:Interesting, I have been trying to find ways to slow down the returning water - possibly through Actuators in my Radiant loop manifold etc. This looks like a viable and less complicated alternative. One question I have is where it should be located. I have a bypass valve (manual valve) that I placed in the line right above the boiler with it staying at 1/4 open. This keeps the returning water from what I have termed "tanking" the boiler where the return temp drops the boiler temp 20+ degrees. Then it takes a day's age to recover. It helps slightly, but still is nowhere near what I need. This valve looks like this may be another good option and would probably solve or reduce my creosote issue - which can be substantial.

Placement is a question. I have so much water in the system, it takes so long for the boiler to affect the return water temp from the radiant (and to a lesser degree of the baseboard) - if at all. I could see my boiler running for hours before it is going full speed to the heating loops. I assume I would want it on the return line as in the attached diagram recommended by the manufacturer as close to the other loop as possible?

I know nothing about the make of your boiler and how it burns but what you say is that you have a boiler firing flat out and not keeping up with demand yet you are saying you have a creosote issue. I will side with Willman and suspect you may have a moisture content issue with your wood.

I burn Maple and White Birch - pretty much the staples around here which has cured under a lean-to for a year. I don't doubt that it could be dryer, but it also seems that when the boiler returns such cold water it appears that there is condensation that occurs. I notice this especially when I am not running the baseboard from the boiler and therefore turn down the set-point to accomodate just the radiant. Then the return water may get below 120-130. Earlier in the winter I turned the set-point up to 170-180 to accomodate the heating demands and the creosote was not as significant. I appreciate the feedback as I continue to learn more about this system every day, and everything helps! I also am happy to say that I finally got a year ahead on my wood pile for next winter which has been curing since last summer.

Kawliga

New Member

NE Wonder....

Couple of questions...what is your boiler capaity? Do you know the fluid capacity of your radiant and baseboards? What temp does your boiler get up to...you should only need 110 to 120 degree water in your radiant loops?

I had same issue with my Benjamin oil/wood combo...40 gallon capaity in boiler, 80 gallons in my radiant loops....when burning wood, my Benjamin could not keep up, but as another member noted, wood is nowhere near as fast as oil/gas/propane....so it take a while to get that water up to temp....and because of the cooler return water, it never will. If I used the oil part of my boiler it could keep up, barely, but it really sucked back the oil. The Danfoss will help as it will limit the cooler retrun temp water from cooling down the boiler....but IMO, sorry to say, will not fully solve your problem...depends quite a bit on what the temps are going out, and what the return temps are....if there is too much of a Delta, the Danfoss will just be recirculating to the boiler, and not to the emitters...

I think some form of well insulater storage is in order to bring up your capacity, in addition to the Danfoss....

I ended up switching to a CB 6048 which has almost 400 gallon capacity....I dont use the Benjamin anymore....

BTW, I do not think you have a wood issue or moisture issue IMO

Good Luck

Mike

Couple of questions...what is your boiler capaity? Do you know the fluid capacity of your radiant and baseboards? What temp does your boiler get up to...you should only need 110 to 120 degree water in your radiant loops?

I had same issue with my Benjamin oil/wood combo...40 gallon capaity in boiler, 80 gallons in my radiant loops....when burning wood, my Benjamin could not keep up, but as another member noted, wood is nowhere near as fast as oil/gas/propane....so it take a while to get that water up to temp....and because of the cooler return water, it never will. If I used the oil part of my boiler it could keep up, barely, but it really sucked back the oil. The Danfoss will help as it will limit the cooler retrun temp water from cooling down the boiler....but IMO, sorry to say, will not fully solve your problem...depends quite a bit on what the temps are going out, and what the return temps are....if there is too much of a Delta, the Danfoss will just be recirculating to the boiler, and not to the emitters...

I think some form of well insulater storage is in order to bring up your capacity, in addition to the Danfoss....

I ended up switching to a CB 6048 which has almost 400 gallon capacity....I dont use the Benjamin anymore....

BTW, I do not think you have a wood issue or moisture issue IMO

Good Luck

Mike

willworkforwood

Feeling the Heat

It sounds like you have 2 problems with your system. As others have said, the 140+ return protection is mandatory. Is there a near boiler return loop piped in, and just doesn't have a mixing valve? Or, is there no near boiler return loop at all? You mentioned a "heating guy" and a field rep. Did they do the install? In any case, you need to get that fixed ASAP, because your boiler is probably already starting to rust away.NE Wonder said:... but it also seems that when the boiler returns such cold water it appears that there is condensation that occurs. I notice this especially when I am not running the baseboard from the boiler and therefore turn down the set-point to accomodate just the radiant. Then the return water may get below 120-130. Earlier in the winter I turned the set-point up to 170-180 to accomodate the heating demands and the creosote was not as significant. ....

But beyond that big problem, it sounds like you might be trying to run your boiler with a combination of a big fire and too low of a set point. If you run even close to a full firebox of wood, and a boiler water temp of less than 170, you would have nothing but a smouldering fire. This would also explain the large amount of creosote that you describe (regardless if the wood is seasoned or not). How much wood are you loading - do you always have a big fire going? It's very hard to keep a good sized wood boiler under 170 (or even 180). I do it occasionally, but never with anything other than a very small fire (i.e. 3-6 small splits). Best of luck getting your boiler problems resolved soon.

Kawliga, sounds like your earlier situation was similar to mine. Basically what I have figured is that the boiler gets 20 gal (in the water jacket) up to temperature, then dumps it into the heating loop. The return water drops the temperature 10 or so degrees and the circulator to the boiler stops (the heating loop keep circulating the previously heated water) and the fan kicks in to amp up the temperature and therefore bring the next 20 gallons up to temperature. This process takes roughly 5-7 minutes until the boiler turns those 20 gallons loose into the system. In the meantime, the previously heated water has cooled down to room temperature and therefore sends back colder water to the boiler where the circulator stops and the above cycle starts all over again. After more thought, the Danfoss Valve would help if the set-point is close to the 140 degrees so it doesn't take so long to cycle, but once opening up to the heating loop, it would take presumibly hours for the heating loop to gain in temperature enough so the hot water will circulate all throughout and then return to the boiler. I go back to the idea of acctuators that I had to basically make my 12 loop manifold (200 ft. per loop) break down into three zones which would reduce the demand on all that water coming back at once. Right now, if I turn all but three loops off on my manifold, and only allow those three to circulate, the return temperature starts rising within 10-15 minutes or so. Something that would never happen if I ran all 12 loops at the same time even if the boiler ran all night - it may rise 5-10 degrees on the return manifold. My thoughts were if I only allowed a few loops to circulate at a time, I would reduce the volume of return water.

Now, when I run the propane, it works well! Heat, comfortable, even warmth. The reason is that the Propane is constantly applying heat and can keep up with the return water. With the propane, the entire 12 loops on the radiant manifold jumps 15 degrees within the first 10 minutes.

Willworkforwood, I usually run the water temperature at 180 degrees (mixing valves on the Radiant bring it down to 120 on the Radiant loops) to account for the baseboard. I tested it on a lower set-point and that was what I found out. As mentioned above the circulator stops bringing back return water once I lose 10 degress on the set-point. So, I can keep the water in the boiler above 140 degrees, it's just that the remainder of the water in the system cools down while the boiler is cycling.

I am in the process of finding out the fluid capacity of the boiler, I have a call into the company as I can't find it online.

Now, when I run the propane, it works well! Heat, comfortable, even warmth. The reason is that the Propane is constantly applying heat and can keep up with the return water. With the propane, the entire 12 loops on the radiant manifold jumps 15 degrees within the first 10 minutes.

Willworkforwood, I usually run the water temperature at 180 degrees (mixing valves on the Radiant bring it down to 120 on the Radiant loops) to account for the baseboard. I tested it on a lower set-point and that was what I found out. As mentioned above the circulator stops bringing back return water once I lose 10 degress on the set-point. So, I can keep the water in the boiler above 140 degrees, it's just that the remainder of the water in the system cools down while the boiler is cycling.

I am in the process of finding out the fluid capacity of the boiler, I have a call into the company as I can't find it online.

Kawliga

New Member

yup, sure sounds similar....we struggled with the Benjamin for 5 years....we didn't install actuators, but put in programmable tstats. We have 7 zones, all with a tstat and all with their own circulator. Set these so that no more than 2 or 3 zones would come on at a time and set them up to rotate.

The tstats, in combination with very hot fires saw us thru those 5 years but a huge PIA....we managed to keep the house reasonably comfortable, (nowhere near what my wife and family prefer but comfortable). It was high maintenance heating, albeit we didnt use hardly any oil the last 4 years, just when we went away. That said, the amount of time spent stoking the fire to keep it running real hot, (stack temps between 400 and 500 F), extra dry good quality hardwoods, (only maple and red oak), and the amount of cleaning required, (because we had to run the boiler as hot as we could, somewhat incomplete combustion means lots of coals), we had to clean out the boiler every 2 to 3 days....messy dirty job....the Benjamin is dutch overn type, round firebox....

Nowhere near what I would call ideal setup or efficient....but it worked....as I noted this year we had finally had enough and switched to the CB 6048 OWB...it literally has changed our lives during the heating season....for the better of course...no longer do we separate our zones, all the tstats are set to what we want when we want and the OWB keeps up with no issue....also house is a ton warmer than before....and you just have to love 12 to 24 or more hour burn times...especially when we were used to 2 or 3 hour burn time in the past....this year we wonder how we ever found the time to keep up....and now enjoy our extra spare time getting wood and doing other things that dnt eveolve around being a slave to your boiler...

Hope you can find a resolution....thinking some form of storage....and also you may want to consider some additional expert help...sorta sounds like your installer and his assistant arent going to be much help...

Mike

The tstats, in combination with very hot fires saw us thru those 5 years but a huge PIA....we managed to keep the house reasonably comfortable, (nowhere near what my wife and family prefer but comfortable). It was high maintenance heating, albeit we didnt use hardly any oil the last 4 years, just when we went away. That said, the amount of time spent stoking the fire to keep it running real hot, (stack temps between 400 and 500 F), extra dry good quality hardwoods, (only maple and red oak), and the amount of cleaning required, (because we had to run the boiler as hot as we could, somewhat incomplete combustion means lots of coals), we had to clean out the boiler every 2 to 3 days....messy dirty job....the Benjamin is dutch overn type, round firebox....

Nowhere near what I would call ideal setup or efficient....but it worked....as I noted this year we had finally had enough and switched to the CB 6048 OWB...it literally has changed our lives during the heating season....for the better of course...no longer do we separate our zones, all the tstats are set to what we want when we want and the OWB keeps up with no issue....also house is a ton warmer than before....and you just have to love 12 to 24 or more hour burn times...especially when we were used to 2 or 3 hour burn time in the past....this year we wonder how we ever found the time to keep up....and now enjoy our extra spare time getting wood and doing other things that dnt eveolve around being a slave to your boiler...

Hope you can find a resolution....thinking some form of storage....and also you may want to consider some additional expert help...sorta sounds like your installer and his assistant arent going to be much help...

Mike

Singed Eyebrows

Minister of Fire

It sounds like you might have a draft issue if your wood is dry enough. With dry wood & good draft you should get some decent heat out of that even though it isn't a gasser, RandyNE Wonder said:I just finished a new heating system and went with a New Yorker 130 wood boiler with a wall-mount propane boiler as a secondary boiler. I run both Radient heat and baseboard off this set-up as I have existing structure and a new addition. My problem is that the wood boiler gets the water in the boiler up to temperature and then dumps it into the heating loop, and within a minute or two, the returning water from the house cools the boiler down and then starts the cycle of the boiler needing to get the returning 20 gallons of water back up to temperature. This can take 7-9 minutes based on the fire. By that time, the hot water that is circulating in the house is cold again. When sizing my system, the heating contractor said I needed 80,000 BTU's, and we went with a 130 to allow for overage. Therefore, it doesn't appear that I am undersized. The propane works well, but it uses propane which is my problem there! I would like to have a heating system that doesn't burn so much propane through the winter months. I was hoping this wood boiler would be able to stand alone 80-90% of the time, but it is just not doing it. I thought about even getting a different boiler such as a gasification boiler or coal that may be able to have a shorter recoup time. I could really use some help here as I have had my heating guy and a field rep from the distributor come and look at my system. The end result is both of them shaking their heads and walking away with no great ideas. Thoughts? Ideas?

Paver56

Member

I feel your pain. I too have a New Yorker WC 130. My experience is that burning coal works great if you can tend it every 3 or 4 hours. I put fire brick around the inside, replacing the steel that comes with it. That allows me to have a deeper bed of coal. The last 2 months I have been burning only wood. I have over 7000 ft of pex in my house. The wood burns good too but I still have to tend it every couple of hours. I also have a creosote problem.

Personally, I would not wish this boiler on my worst enemy unless they wanted to get very little sleep or deal with a cold house every morning. I have not paid for the wc130 yet. I know the guy that put it in for me and he knows that it is not getting sufficient burn times. I have even talked to the factory and they told me that they aren't designed to get for than 4-6hrs of burn time.

I hope that you are able to work out your issues. I am returning mine this summer and installing eithe a Froling or an Effecta with storage. I am really looking forward to being able to sleep through the night next season.

Personally, I would not wish this boiler on my worst enemy unless they wanted to get very little sleep or deal with a cold house every morning. I have not paid for the wc130 yet. I know the guy that put it in for me and he knows that it is not getting sufficient burn times. I have even talked to the factory and they told me that they aren't designed to get for than 4-6hrs of burn time.

I hope that you are able to work out your issues. I am returning mine this summer and installing eithe a Froling or an Effecta with storage. I am really looking forward to being able to sleep through the night next season.

Paver56

Member

I forgot to mention that I have all radiant and that burning with coal seems to regulate the temp a lot better. I also have a wall mounted condensing propane boiler.

These boilers are a big investment and if you cannot get your problems solved, I would try to get them to return the boiler. The thing that upset me the most is that they told me that I should not expect to get an overnight burn. I told them that there literature is quite misleading if that is the case. The factory guy I spoke to said that it is designed as and add on boiler and not meant to be the sole heat source.

These boilers are a big investment and if you cannot get your problems solved, I would try to get them to return the boiler. The thing that upset me the most is that they told me that I should not expect to get an overnight burn. I told them that there literature is quite misleading if that is the case. The factory guy I spoke to said that it is designed as and add on boiler and not meant to be the sole heat source.

Ben, thanks for the reply, although feeling more disheartened about my ability to get this thing to work, it seems like I am facing reality. I have 2400 ft. of pex radiant and 50 feet of baseboard. I haven't turned on the basement radiant because the system can't sustain the living areas. The wall-mounted condensing propane keeps the place comfortable, the wood on it's own doesn't. It can't keep up with the baseboard by itself all night (not counting the radiant). I called the rep. yesterday from New Yorker to figure out the "water capacity" answer as posted above. Needless to say he didn't let me get a word in edgewise to explain my problem. He was quick to say that the boiler is not a sole heat source and interrupted me when I explained how it would not handle the load. Then he said the water in my system is "nothing" for the boiler and that it can handle it easily. Yet I am confused if it can handle it "easily", why it can't work on it's own. To me he sounded quite defensive and was looking for any opportunity to say it wasn't the boiler's issue. I never placed the problem there with him, I was trying to figure out how I can best set-up this system. Wonder how many of these calls he gets.

I'm toying around with the idea of storage, do you have any? Thought that might help with the cycling issue as it can take 7-9 minutes to cycle another batch of hot water. Can't figure it out, a friend has the same boiler and he gets 10 hour burn time and warm/cozy house running this as his primary during cold weather. Just my luck...

I'm toying around with the idea of storage, do you have any? Thought that might help with the cycling issue as it can take 7-9 minutes to cycle another batch of hot water. Can't figure it out, a friend has the same boiler and he gets 10 hour burn time and warm/cozy house running this as his primary during cold weather. Just my luck...

willworkforwood

Feeling the Heat

heaterman

Minister of Fire

A couple comments...........

Any wood boiler needs to be maintained at 150* water temp or higher. Running below that point gets you into the condensation area and as you have discovered, that is not a happy situation.

As others have said, a solid fuel boiler is not an instant on appliance like a gas or oil fired boiler would be. It takes a while to get the fire ramped up to full output, especially when it's trying to meet the building load as well as warm itself up. When the boiler is sized closely to the required heat output, it can be a real struggle.

BTU storage of some type would really help your situation along with some kind of boiler protection mixing device. Either a Termovar type valve or an injection mixing circ set up to protect the boiler would help your situation out immensely.

If you have a high mass radiant slab, it is nearly mandatory to have some kind of storage to cope with the huge btu load dumped on the system when it calls for heat. Can it be done other ways? Yes, but you'll find that a healthy amount (minimum of 300-500 gallons of water stored at 180* or so is far simpler than trying to out engineer what is happening in your system.

A stop gap measure you might consider would be to run your boiler at 180 all the time and use a mixing valve to drop the temp to your radiant floor rather than lowering the boiler temp. That would be far better for the boiler than trying to make it do something it is not designed to do. Namely, running at <150*.

Any wood boiler needs to be maintained at 150* water temp or higher. Running below that point gets you into the condensation area and as you have discovered, that is not a happy situation.

As others have said, a solid fuel boiler is not an instant on appliance like a gas or oil fired boiler would be. It takes a while to get the fire ramped up to full output, especially when it's trying to meet the building load as well as warm itself up. When the boiler is sized closely to the required heat output, it can be a real struggle.

BTU storage of some type would really help your situation along with some kind of boiler protection mixing device. Either a Termovar type valve or an injection mixing circ set up to protect the boiler would help your situation out immensely.

If you have a high mass radiant slab, it is nearly mandatory to have some kind of storage to cope with the huge btu load dumped on the system when it calls for heat. Can it be done other ways? Yes, but you'll find that a healthy amount (minimum of 300-500 gallons of water stored at 180* or so is far simpler than trying to out engineer what is happening in your system.

A stop gap measure you might consider would be to run your boiler at 180 all the time and use a mixing valve to drop the temp to your radiant floor rather than lowering the boiler temp. That would be far better for the boiler than trying to make it do something it is not designed to do. Namely, running at <150*.

heaterman said:A couple comments...........

Any wood boiler needs to be maintained at 150* water temp or higher. Running below that point gets you into the condensation area and as you have discovered, that is not a happy situation.

As others have said, a solid fuel boiler is not an instant on appliance like a gas or oil fired boiler would be. It takes a while to get the fire ramped up to full output, especially when it's trying to meet the building load as well as warm itself up. When the boiler is sized closely to the required heat output, it can be a real struggle.

BTU storage of some type would really help your situation along with some kind of boiler protection mixing device. Either a Termovar type valve or an injection mixing circ set up to protect the boiler would help your situation out immensely.

If you have a high mass radiant slab, it is nearly mandatory to have some kind of storage to cope with the huge btu load dumped on the system when it calls for heat. Can it be done other ways? Yes, but you'll find that a healthy amount (minimum of 300-500 gallons of water stored at 180* or so is far simpler than trying to out engineer what is happening in your system.

A stop gap measure you might consider would be to run your boiler at 180 all the time and use a mixing valve to drop the temp to your radiant floor rather than lowering the boiler temp. That would be far better for the boiler than trying to make it do something it is not designed to do. Namely, running at <150*.

heaterman, I think you summed up the two options I have available to me. The boiler protection mixing device may help, although I still wonder if I can see the difference in anything less than a few hours of run time given how slow it takes for my return water to warm. Nevertheless, it theoretically should help. As for the storage, that makes some sense as well, given the high mass I have in the radiant (gypcrete overpour) which again the return water takes forever to warm up. I already have the stop gap measure in place and have mixing valves on the radiant loop and run my radiant at 120. As mentioned before, I run the boiler at 170-180 unless I am "testing" a brainstorm. What amazes me is that I roughly calculated that I probably have around 35 - 40 gallons of water in the system (not counting the 21 in the boiler). This doesn't seem like a whole lot, and therefore makes me wonder if the storage will make a huge difference.

heaterman

Minister of Fire

NE Wonder said:heaterman said:A couple comments...........

Any wood boiler needs to be maintained at 150* water temp or higher. Running below that point gets you into the condensation area and as you have discovered, that is not a happy situation.

As others have said, a solid fuel boiler is not an instant on appliance like a gas or oil fired boiler would be. It takes a while to get the fire ramped up to full output, especially when it's trying to meet the building load as well as warm itself up. When the boiler is sized closely to the required heat output, it can be a real struggle.

BTU storage of some type would really help your situation along with some kind of boiler protection mixing device. Either a Termovar type valve or an injection mixing circ set up to protect the boiler would help your situation out immensely.

If you have a high mass radiant slab, it is nearly mandatory to have some kind of storage to cope with the huge btu load dumped on the system when it calls for heat. Can it be done other ways? Yes, but you'll find that a healthy amount (minimum of 300-500 gallons of water stored at 180* or so is far simpler than trying to out engineer what is happening in your system.

A stop gap measure you might consider would be to run your boiler at 180 all the time and use a mixing valve to drop the temp to your radiant floor rather than lowering the boiler temp. That would be far better for the boiler than trying to make it do something it is not designed to do. Namely, running at <150*.

heaterman, I think you summed up the two options I have available to me. The boiler protection mixing device may help, although I still wonder if I can see the difference in anything less than a few hours of run time given how slow it takes for my return water to warm. Nevertheless, it theoretically should help. As for the storage, that makes some sense as well, given the high mass I have in the radiant (gypcrete overpour) which again the return water takes forever to warm up. I already have the stop gap measure in place and have mixing valves on the radiant loop and run my radiant at 120. As mentioned before, I run the boiler at 170-180 unless I am "testing" a brainstorm. What amazes me is that I roughly calculated that I probably have around 35 - 40 gallons of water in the system (not counting the 21 in the boiler). This doesn't seem like a whole lot, and therefore makes me wonder if the storage will make a huge difference.

RE: storage

A radiant floor will pull all the "heat" out of 60 or so gallons of water in one round trip more or less. If you are working from storage you basically have a larger flywheel to counteract the flywheel in your floor. Without that, it comes down to nothing more than raw horsepower needed to meet the load as well as keep the boiler up to temp. 300 gallons of storage for example with a 30* drop 180-150 will provide roughly 80,000 btu's of heat to your floor unassisted by the boiler. This allows time for the fire to get rolling before having to actually meet the load head on. There are only two ways to fight a high mass "radiator" like your floor. Raw horsepower or with an equal amount of mass.

Paver56

Member

NE Wonder- I do not have storage. I am going to install storage with my new gassifier (when I get it) I too have thought of adding storage and I think that it would help but I came to the realization that a gasser would be much more efficient. Burning coal in my wc130 makes a ton of heat. The problem is that getting a good coal fire going takes at least an hour. I would much rather be able to light a fire in a couple of minutes and walk away. The other problem with coal is the amount of ash and this boiler seems prone to a lot of clinkers. I figure if I am going to spend money on a boiler, I want it to be something I enjoy and look forward to lighting, not something I dread dealing with. If you don't mind me asking, how much did you pay for the wc130?

heaterman

Minister of Fire

Want storage? Want to light a fire and walk away? Want a boiler that is nearly impervious to low return temperature? Get a Garn. My 11 year old grand daughter can load theirs when dad is not around.

I am working on storage ideas, can anyone direct me to some good DIY plans? I have access to a 320 gallon propane tank that should cost next to nothing. Seems like that is a preferred method from what I read on here. Problem is it is 20 inches to tall to stand on end, which seems to be critical for stratification. Contemplating blocking it up on an angle (possibly welding legs), but not a big fan of the idea. Just trying to work with this cheap, hard to find tank. Really not interested in spending another $1,000+ on storage. Any thoughts or direction would be helpful! Seems like 300 gallons is as low as I would like to go, need 80,000 BTU's per the "sizing" formula.

ewdudley

Minister of Fire

NE Wonder said:I am working on storage ideas, can anyone direct me to some good DIY plans? I have access to a 320 gallon propane tank that should cost next to nothing. Seems like that is a preferred method from what I read on here. Problem is it is 20 inches to tall to stand on end, which seems to be critical for stratification. Contemplating blocking it up on an angle (possibly welding legs), but not a big fan of the idea. Just trying to work with this cheap, hard to find tank. Really not interested in spending another $1,000+ on storage. Any thoughts or direction would be helpful! Seems like 300 gallons is as low as I would like to go, need 80,000 BTU's per the "sizing" formula.

Vertical happened to be doable in my situation, but from from reading here and by the nature of the problem it's clear that horizontal tanks work quite well.

The only trick is in avoiding vertical jets of water entering the tank when charging the top of the tank or when returning spent water to the bottom. Some guys have had horizontal pipes welded in at the top and bottom of the horizontal tanks, others have used simple diffusers in the existing ports, and others still just use fat pipes with the existing ports and find there's no big problem.

Plus if you're really feeding an 80,000 btu per hour load a 320 gallon tank would be more of a buffer tank than a storage tank and stratification wouldn't be such a big deal to begin with. Definitely worth doing though, it would help insure than when the boiler is running it can run flat-out hot and clean for an hour or two at a time.

--ewd

Willman

Minister of Fire

Problem is it is 20 inches to tall

Is there a possibility of excavating a couple of feet for clearance ? Pour a new pad and allow space for insulation piping etc. Same gallons as horizontal but less of a footprint.

Will

- Status

- Not open for further replies.

Similar threads

- Replies

- 12

- Views

- 1K

- Replies

- 6

- Views

- 1K

- Replies

- 22

- Views

- 721

- Replies

- 9

- Views

- 2K