In my never ending quest to learn about or speed up the drying process, I started another drying experiment.

Supposedly we are getting closer to wood drying season in the PNW although proof is scarce. I cut a friends tree down about 2 months ago, bucked, split and stacked it the same day. I thought I would see how some of the splits dried compared to putting one in the garage. I put a fan on low in the garage to stir the air. You can't really feel any breeze at the split's location as much as an awareness that there is some air movement. I think this is relevant to a lot of posts on this forum as folks generally recommend season their wood outside and then stack it in their sheds. But if folks don't want to stack twice, a little forced air movement in a shed will dry a lot of wood.

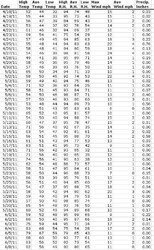

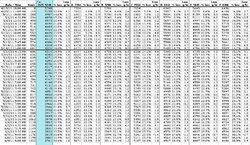

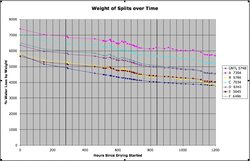

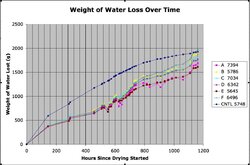

My goals were to both compare the drying speeds of indoor in the shade with slight air movement compared to outdoor in the sun, wind and rain and also see how drying outside changes with the weather. No surprise, the wood doesn't dry when its raining, but the moisture added is quickly lost the next dry day. What is clear is that so far with our climate and weather, the wood dries very little at night, but drying rates can go as high as 20g/ hour during a warm sunny period. That rate would dry my wood in 7 days if it started at 100% MC. But of course drying rates will always decrease as the moisture content of the wood gets closer to outside EMC conditions. As you would expect the piece in the garage dries more evenly, a little more quickly when its warmer in the day but not like being out in the sun and wind. But since it is drying day and night, it has lost 34% of its weight versus an average of 28% for the outside splits after 1200 hours. The difference was more significant after 600 hours when it had lost 25% verses and ave. of 14.8%. The warm weather of summer will no doubt catch up the outside pieces.

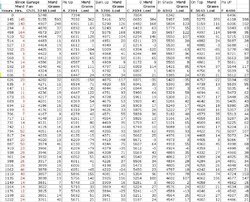

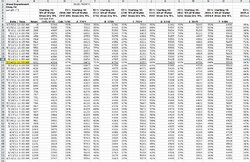

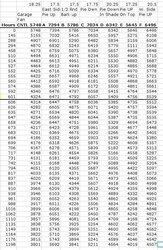

What has surprised me was the consistency sometimes of water lost between the different sized pieces. As an example, after one 18 hour period, 4 of the 6 pieces lost between 111-117 grams of water. I have calculated all kinds of stats from % moisture lost to grams/ hour drying rates, most of which would bore you enough to cause you to go stack wood. One month (600 hours) into it, I changed things up a bit covering 2 of the pieces with plywood, 2 with clear roofing and leaving 2 in the open. See pic. No doubt there will be a trade off between keeping the rain off and warming up in the sun.

Anyway thought I would report the stutus so far. The splits I measured were my average burning size (Doug F.) and ranged from 5645-7394 g (12.4-16.3 lbs). My control in the garage started at 5748g. You can see the stack is a pretty ideal for drying, single row on asphalt with plenty of wind, other than there is no cover. Stack runs exactly E-W, on asphalt, with great S. exposure and wind. You can see the 6 splits marked in the pile. After 600 hours changed the stack to some covered and not as shown. I was weighing weekly at first and then started weighing daily or even after a few hours if it was warm and sunny to see the difference. My clock started at 10am on April 19th, 2011. The stage 2 picture is how I moved the 6 splits after 600 hours.

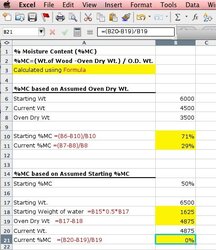

Until I do an oven dry I won't know their actual moisture content but the last picture is a spreadsheet shot that lets me assume some figures to help calculate their MC until I do an oven dry.

We had our first 80 degree day last weekend and some of the splits lost almost 300 g in 2 days! Looking forward to summer!

Supposedly we are getting closer to wood drying season in the PNW although proof is scarce. I cut a friends tree down about 2 months ago, bucked, split and stacked it the same day. I thought I would see how some of the splits dried compared to putting one in the garage. I put a fan on low in the garage to stir the air. You can't really feel any breeze at the split's location as much as an awareness that there is some air movement. I think this is relevant to a lot of posts on this forum as folks generally recommend season their wood outside and then stack it in their sheds. But if folks don't want to stack twice, a little forced air movement in a shed will dry a lot of wood.

My goals were to both compare the drying speeds of indoor in the shade with slight air movement compared to outdoor in the sun, wind and rain and also see how drying outside changes with the weather. No surprise, the wood doesn't dry when its raining, but the moisture added is quickly lost the next dry day. What is clear is that so far with our climate and weather, the wood dries very little at night, but drying rates can go as high as 20g/ hour during a warm sunny period. That rate would dry my wood in 7 days if it started at 100% MC. But of course drying rates will always decrease as the moisture content of the wood gets closer to outside EMC conditions. As you would expect the piece in the garage dries more evenly, a little more quickly when its warmer in the day but not like being out in the sun and wind. But since it is drying day and night, it has lost 34% of its weight versus an average of 28% for the outside splits after 1200 hours. The difference was more significant after 600 hours when it had lost 25% verses and ave. of 14.8%. The warm weather of summer will no doubt catch up the outside pieces.

What has surprised me was the consistency sometimes of water lost between the different sized pieces. As an example, after one 18 hour period, 4 of the 6 pieces lost between 111-117 grams of water. I have calculated all kinds of stats from % moisture lost to grams/ hour drying rates, most of which would bore you enough to cause you to go stack wood. One month (600 hours) into it, I changed things up a bit covering 2 of the pieces with plywood, 2 with clear roofing and leaving 2 in the open. See pic. No doubt there will be a trade off between keeping the rain off and warming up in the sun.

Anyway thought I would report the stutus so far. The splits I measured were my average burning size (Doug F.) and ranged from 5645-7394 g (12.4-16.3 lbs). My control in the garage started at 5748g. You can see the stack is a pretty ideal for drying, single row on asphalt with plenty of wind, other than there is no cover. Stack runs exactly E-W, on asphalt, with great S. exposure and wind. You can see the 6 splits marked in the pile. After 600 hours changed the stack to some covered and not as shown. I was weighing weekly at first and then started weighing daily or even after a few hours if it was warm and sunny to see the difference. My clock started at 10am on April 19th, 2011. The stage 2 picture is how I moved the 6 splits after 600 hours.

Until I do an oven dry I won't know their actual moisture content but the last picture is a spreadsheet shot that lets me assume some figures to help calculate their MC until I do an oven dry.

We had our first 80 degree day last weekend and some of the splits lost almost 300 g in 2 days! Looking forward to summer!

Attachments

-

Woodpile2 due south.jpg216.3 KB · Views: 671

Woodpile2 due south.jpg216.3 KB · Views: 671 -

Screen shot 2011-06-08 at 8.14.43 AM.jpg96.7 KB · Views: 706

Screen shot 2011-06-08 at 8.14.43 AM.jpg96.7 KB · Views: 706 -

Screen shot 2011-06-07 at 10.49.53 AM.jpg97.7 KB · Views: 703

Screen shot 2011-06-07 at 10.49.53 AM.jpg97.7 KB · Views: 703 -

Raw Data Hours.jpg143 KB · Views: 705

Raw Data Hours.jpg143 KB · Views: 705 -

Stage 2.jpg140 KB · Views: 683

Stage 2.jpg140 KB · Views: 683 -

Screen shot 2011-06-07 at 12.27.52 PM.jpg55 KB · Views: 705

Screen shot 2011-06-07 at 12.27.52 PM.jpg55 KB · Views: 705