Yeah, I did a vinegar boil on a steel cat that had died with success. In my case it had lived a much longer life than yours, closer to 8000 hours as I recall, but had totally died. Seems catalysts stop working when the precious metals are masked by junk from the burn. Like a coating that prevents the smoke from contacting the catalyst. By definition, a catalyst is not "consumed" but is covered up or flattened out by thermal shock so that its surface area is too small.

It's easy to try, you've already got the cat out. Steal some white vinegar from the canning supplies. Boil it on a camp stove or a BBQ side burner outside to burn off the coating. Then rinse with distilled water to neutralize the acid. You can search for the thread under my username.

Honestly, if you're setup physically destroys ceramic cats then you have a massive air leak and are thermally shocking your catalyst hard. That abuse will kill a steel cat too it's just that you won't get a visible physical degradation. 95% of cats are eventually killed by thermal shock is what the manufacturer tells us. Metal cats are inferior. The only advantage is that they don't visibly break so less warranty calls to the manufacturer.

Ah... the original source appears, thanks for your thoughts. I agree with everything you said above, almost...

Catalyst masking: Yep I agree, all makes sense and my wife makes pickles, so I got vinegar.

I typically go through a ceramic cat every 2-3 years. Failure mode is structural, it just falls apart. Interesting though that the frame on the metal cat is perfect, my ceramics usually get pretty warped and bowed.

I also see a fair bit of spalling in my refractory, I have replaced the "engine" twice in ten years, complete stove teardown and rebuild. (I burn 4 cord a year, primary heat Nov - March, 24/7, ~3500hrs/year)

Not sure how familiar you are with the VC design but I suspect there is a design issue resulting in flame impingement on the cat and mixing of secondary air with the primary burn causing over firing.

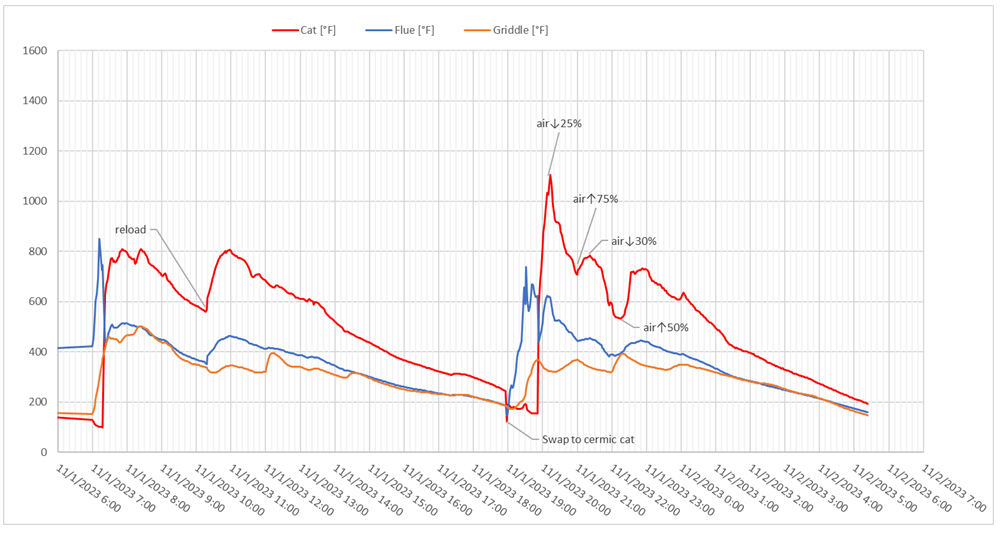

My best evidence for not having an air leak is: With the cat engaged I can close my air down all the way and the flames all but go out. If there is enough fuel/ heat in the primary burn the cat temps will rocket to 1400 - 1700 and hang there for hours. Occasionally the stove will start back puffing, because the primary burn is starved for air. Air builds up in the primary burn and then all at once the gas ignites and then goes out, this pushes a puff of smoke out the griddle gasket....

Second best evidence: This stove has always behaved this way since new, after two complete rebuilds (all new gasketing) its bad attitude has never changed, similar to the way my teenaged children were.... haha

And.... it does not do this all the time, in fact I would estimate less than 30% of my burns go badly. I would expect an air leak to be more consistent.

Still searching for the answer.....

Your comment about the metal cat failure mode matches my limited experience, it looks fine, but does not perform fine any more.