Hi All,

I picked up an All Nighter Mid Moe to install in a pole barn shop we just put up.

The stove cleaned up nice, and after replacing firebrick and inspecting everything, I installed as per the manual, and normal installation.

It works fine...goes through a lot of wood, but it is heating 1200 sq' with 19' ceilings...

My concern and question is the way the stove is designed.

I've studied all the information here on them, and the stove itself;

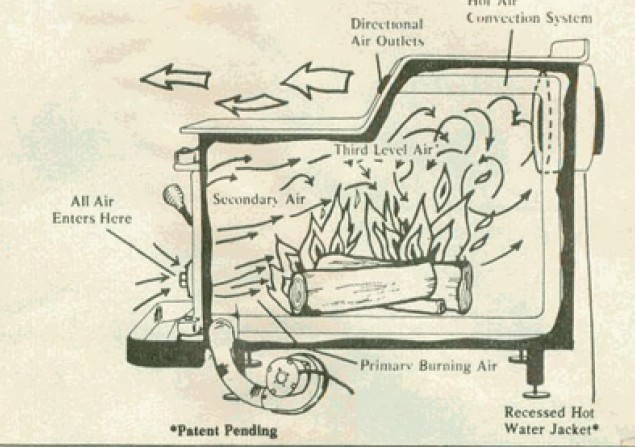

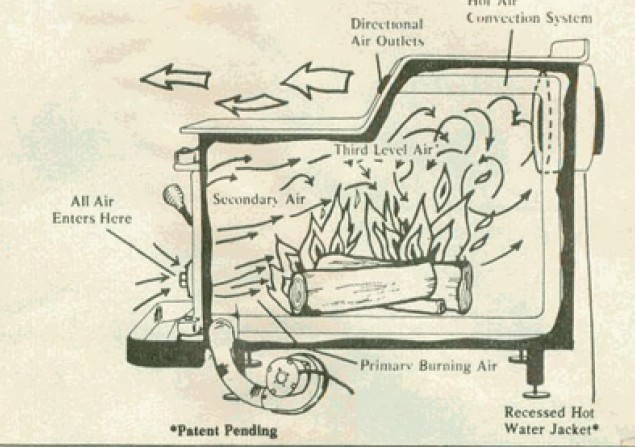

As you can see in the drawing, the flames in the firebox go out the back of the stove, and into the flue.

When reloading, I can see the flames from the fire in the stove going into the flue elbow.

I can't tell how far they are going, but it concerns me.

The stove has a heavy plate steel thimble that runs 8" or so out the back of the stove, that the elbow connects to.

It seems like there should be a baffle, but there isn't, and no signs or clues that there ever was.

I realize that a LOT of heat goes out the back of any stove and into the flue, but seeing flames have/take a direct path into the elbow has me concerned.

Should I be? Should a baffle be installed?

Thanks!

Rob

I picked up an All Nighter Mid Moe to install in a pole barn shop we just put up.

The stove cleaned up nice, and after replacing firebrick and inspecting everything, I installed as per the manual, and normal installation.

It works fine...goes through a lot of wood, but it is heating 1200 sq' with 19' ceilings...

My concern and question is the way the stove is designed.

I've studied all the information here on them, and the stove itself;

As you can see in the drawing, the flames in the firebox go out the back of the stove, and into the flue.

When reloading, I can see the flames from the fire in the stove going into the flue elbow.

I can't tell how far they are going, but it concerns me.

The stove has a heavy plate steel thimble that runs 8" or so out the back of the stove, that the elbow connects to.

It seems like there should be a baffle, but there isn't, and no signs or clues that there ever was.

I realize that a LOT of heat goes out the back of any stove and into the flue, but seeing flames have/take a direct path into the elbow has me concerned.

Should I be? Should a baffle be installed?

Thanks!

Rob