Hello

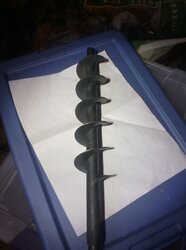

I was working on the Archgard auger see before picture. Not all auger's are the same. Some are nice and shinny and made of stainless steel. However many others are not. Same are metal and some are cast iron. So in the later cases like this Archgard auger, I cleaned it up the best I could using a wire brush and some cleaner. It still looked dingy so I took out the Dry Moly Spray. Wow, it gave it a nice even coat with the High Temp dry moly spray. I put it back and wow it works great!

Any comments? Has anyone tried this? Less Auger Jams!

See pics below. Click to Enlarge.

I was working on the Archgard auger see before picture. Not all auger's are the same. Some are nice and shinny and made of stainless steel. However many others are not. Same are metal and some are cast iron. So in the later cases like this Archgard auger, I cleaned it up the best I could using a wire brush and some cleaner. It still looked dingy so I took out the Dry Moly Spray. Wow, it gave it a nice even coat with the High Temp dry moly spray. I put it back and wow it works great!

Any comments? Has anyone tried this? Less Auger Jams!

See pics below. Click to Enlarge.