NE Wood stove said:

Thanks for all the information. It's all been so very helpful. When I do buy a gasification boiler, it will be replacing a wood-stove. So, I was wondering what you guys recommend for a chimney? Or if I can use the same chimney, it is double wall until it goes to enter thru my foundation, then it is class A thru the foundation and up the outside wall.

Class A prefab chimneys that are OK for a wood stove will be OK for a boiler, with one possible "gotcha" - a lot of wood stove chimneys are only 6" diameter, many boilers are 8"... A lot of the 8" boilers can be necked down to use a 6" flue w/o problems, but you will often need to have some sort of manufacturer statement that it is OK in order to keep your code inspectors happy - obviously if you have an 8" chimney this isn't a problem, but if you have a 6" make sure the manual says the boiler is approved for use w/ a 6" flue.

I'm waiting for info on if the unit is UL approved.

Good question - and sort of a frustrating one, as all the Euro-boilers have had to pass the far stricter EU "EN-303-5" standard, but that isn't acceptable in many jurisdictions... Keep us posted on what you find out. (And be glad you aren't in MA, where we are screwed by a requirement for ASME certification - limiting us to two brands of boilers, and an $800-1,000 surcharge for the extra certification...)

I understand the purpose for a storage tank but how many people actual use them. It's just right now I can only afford the boiler without storage. I'm a little afraid that the unit will tend to over heat if there's no storage for the extra heat to go to. It will be heating baseboard heat so there should be plenty of room for all the hot water. Hoping for radiant in floor heat in the next couple of years.

A lot of us use them, and they are highly recommended, but not absolutely required (unless the manufacturer says so in the manual) - A lot of our members have done "phased" installs where they put in a boiler one year, and then added storage later, either as their finances allowed, or as they found out from experience that we knew what we were talking about :coolgrin: - What we do strongly suggest is that even if not doing storage with the initial install, that you plan for how you would do it, and incorporate any connections needed into the plumbing scheme as you do the initial install - the cost of adding a few extra fittings that are capped off for now is trivial compared to the cost / effort of taking stuff apart to add them in later...

The unit will not overheat w/o storage, instead it will go into "idle mode" which is not very efficient, and tends to smoke a bit, especially when going in and out of idle, but does keep the boiler from overheating, except possibly when there is extremely little call for heat, and usually only then if it was way oversized to begin with... There are ways to operate, even without storage that minimize idling, essentially by building smaller fires and loading more often...

Putting in radiant floor is an excellent idea, especially with storage, as it will generally help you get the maximum benefit from the storage by allowing you to use lower operating temps than you can generally get away with when running baseboard.

I replaced my oil boiler a few years ago but I'm not 100 % sure how to fit the gasification boiler in to the lope. They will probably be about 15 feet away from each other. If anyone knows of any links to a schematic that be awesome. It's a pretty simple set-up right now. There's two loads, one for the first floor and one for the basement. Two zone valves and one circulator.

Josh

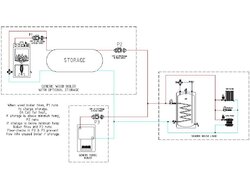

That is usually not a big problem - as I've said, there are lots of approaches, but IMHO one of the best and simplest is to look at it as a "modular block" system - you have a block for "house loads", and a block for your fossil boiler, normally with two pipes connecting the blocks. I like to just put a tee in each one of those two pipes, and attach a "wood block" with the wood boiler and storage system. Leave the zone valves in the "house block" and the pump in the "fossil block", and have a second pump in the wood block. Use the same thermostat and control setup mostly, but add a sensor to the wood block to detect when it is hot enough to supply the house loads. The sensor would operate a relay that intercepts the "call for heat" signal going to the fossil block and sends it to the wood block instead, if the wood block is hot, or sends it to the oil burner if it isn't...

Sort of like the attached sketch... If you do some looking through the other threads, you will also find lots of other options for both plumbing and control strategies...

Gooserider