I'll try to address all of your comments --

First, the stove is a Hobbit:

http://www.salamanderstoves.com/docs/64/the_hobbit_stove/

The flue opening is 4", so I figured I could get a 4" chimney (6 inch outer diameter). We cut a hole in the roof and installed the metal flashing (6") and wove it into the shingles. But then I learned they don't make 4" chimneys in the USA and I would have to special order from Canada (expensive). I was looking at 4" Selkirk HT chimney pipe which was about $200 for a 3' section (comes in 1', 2', 3').

I had wanted to use a chimney box or roof support (I think roof support might make more sense in this installation because it's just a plywood roof) but as you can see we just ran the pipe straight through the roof with no support. It's just being supported by the stove. I don't plan on finishing the walls or ceiling.

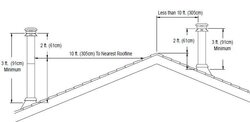

The pipe is 6" single-wall galvanized pipe. It is connected to the stove with a 4" to 6" adapter. There are two 2' sections and one 5' section for a total height of 9'. Add another 6" for the chimney cap. The chimney extends maybe a foot above the roof peak.

The stove manufacturer listed a minimum pipe length of 12', but in an email he said 9' would be ok. The stove is very small, 12x12x18".

Thanks for all the advice guys, this is really helpful.

By the way, since my roof is simply 3/4" plywood, what is the reason for using class A insulated pipe rather than just running double wall stove pipe through the roof? I know everything I have read says you MUST use class A pipe, but all those installations I looked at were going through finished ceilings, not just a sheet of plywood.