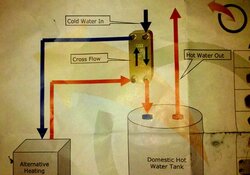

I am in the process of trying to hook in a plate heat exchanger to my electric DHW heater. The instructions/drawings don't show much and I am a little confused on the best approach to take. The drawing shows the cold water in one side of the HX and the hotwater from the boiler on the other side. Simple as that right? Well it seems like if you only did it that way all you would really be doing is heating the water going into the tank instead of continuously heating the water in the tank, so if you were not drawing DHW the electric elements would be doing all the work to heat the tank? Am I missing something here? I was thinking that I may want to put a mixing valve on the DHW-out so the tank would circulate but how does the tank actually circulate through the plate? Convection? Did I screw up and should have got a sidearm?

And where should I put my aquastat to control the pump pushing the boiler water through the HX? I was thinking on the bottom of the DHW tank? It is the external type so I was thinking inside the tank insulation taped to the sidewall of the DHW tank.

Anyways any advice would be great.

Thanks

And where should I put my aquastat to control the pump pushing the boiler water through the HX? I was thinking on the bottom of the DHW tank? It is the external type so I was thinking inside the tank insulation taped to the sidewall of the DHW tank.

Anyways any advice would be great.

Thanks