I

imacman

Guest

Well, even though the stove was all clean last spring, I had decided a while ago to do some preventative maintenance and do a mod that should help with the burn. I know burning weather is (hopefully) at least another 1 1/2 months away, but I'm now 100% ready.

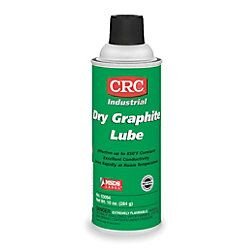

Ordered the "Early bird" gasket set from Englander last May, and decided today was the day to tackle the jobs. Replaced both combustion blower gaskets, and gave the exhaust another quick cleaning w/ the lint eater. Checked the OAK and all seems OK. (btw....that graphite spray treatment on the comb. blower fan blades works GREAT .....almost no buildup when it was cleaned after 1 ton).

.....almost no buildup when it was cleaned after 1 ton).

Then, took the door off and removed the glass (super easy job on this stove), and replaced the door and glass gaskets. They were original to the stove (afaik), so they were 4 yrs old and I thought it was time.

I had also had an idea last winter to add a gasket under the burnpot, and tried it with some scrap pieces of old comb. gasket....seemed to help the flame. So I ordered a couple of sheets of the Lytherm gasket, and made a custom 1-piece burnpot gasket. I also made a gasket "wrap" to go around the stirrer to seal off that opening into the pot too.

And since I had the burn pot and stirrer out, I gave the inside of the pot and the stirrer the graphite spray treatment too.

Last item was to replace the ignitor....old one was only getting hot halfway and start-ups were getting a little long, although it DID still ignite the pellets.

OK.....yeah, I know....no pics = it didn't happen I beat you guys to it:

I beat you guys to it:

Ordered the "Early bird" gasket set from Englander last May, and decided today was the day to tackle the jobs. Replaced both combustion blower gaskets, and gave the exhaust another quick cleaning w/ the lint eater. Checked the OAK and all seems OK. (btw....that graphite spray treatment on the comb. blower fan blades works GREAT

.....almost no buildup when it was cleaned after 1 ton).

.....almost no buildup when it was cleaned after 1 ton).Then, took the door off and removed the glass (super easy job on this stove), and replaced the door and glass gaskets. They were original to the stove (afaik), so they were 4 yrs old and I thought it was time.

I had also had an idea last winter to add a gasket under the burnpot, and tried it with some scrap pieces of old comb. gasket....seemed to help the flame. So I ordered a couple of sheets of the Lytherm gasket, and made a custom 1-piece burnpot gasket. I also made a gasket "wrap" to go around the stirrer to seal off that opening into the pot too.

And since I had the burn pot and stirrer out, I gave the inside of the pot and the stirrer the graphite spray treatment too.

Last item was to replace the ignitor....old one was only getting hot halfway and start-ups were getting a little long, although it DID still ignite the pellets.

OK.....yeah, I know....no pics = it didn't happen

I beat you guys to it:

I beat you guys to it: