My in-laws are building a new house and are installing a new Englander NC30 stove, easy enough so far right?

Somehow I have been put in charge of this part of the project since dad knows nothing about proper chimneys, etc. I will be installing a Supervent class A chimney straight up through the roof...still pretty straight forward. Where things take a turn here is that dad went and built the chimney chase without consulting with me about its specific location.

The stove is going in the corner of the living room at a 45* angle on a built up hearth. I wanted the chimney directly above the stove so we could just go straight up, but dad put it right in the corner of the room. So now the stovepipe will need to have a little offset to it (18-20") in about 4' of rise. Also, we will have to use double wall stovepipe because now it will be within 10-12" of the wall by the time it connects to the chimney.

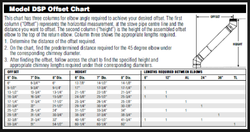

I have been using Selkirks offset chart to try to figure out what exactly to order...then I noticed this phrase on the description of the 45* elbow "Non-positional connection system allows 360 ° rotation".

What exactly does that mean? Does that mean it is basically an adjustable elbow? If so that simplify's things a lot...

That would mean my parts list would be whittled down to (2) 45 elbows and (1) telescoping pipe and (1) stove adapter.

Somehow I have been put in charge of this part of the project since dad knows nothing about proper chimneys, etc. I will be installing a Supervent class A chimney straight up through the roof...still pretty straight forward. Where things take a turn here is that dad went and built the chimney chase without consulting with me about its specific location.

The stove is going in the corner of the living room at a 45* angle on a built up hearth. I wanted the chimney directly above the stove so we could just go straight up, but dad put it right in the corner of the room. So now the stovepipe will need to have a little offset to it (18-20") in about 4' of rise. Also, we will have to use double wall stovepipe because now it will be within 10-12" of the wall by the time it connects to the chimney.

I have been using Selkirks offset chart to try to figure out what exactly to order...then I noticed this phrase on the description of the 45* elbow "Non-positional connection system allows 360 ° rotation".

What exactly does that mean? Does that mean it is basically an adjustable elbow? If so that simplify's things a lot...

That would mean my parts list would be whittled down to (2) 45 elbows and (1) telescoping pipe and (1) stove adapter.