I just might build one. Looking for feedback on my plans, which are preliminary at this point.

Would like to take advantage of the federal 30% tax credit. Current household usage is ~10,000 kWh/year. PVWatts tells me a nominal 8 kW system pointed due south can generate 10,750 kWh in an average year.

8 kW of 335-W panels is 24 panels. A 6x4 grid would cover 32' by 13'.

After the Great Northeast Deluge of 2018, I realized that I need a wood shed to reliably season firewood in my climate. So I'm thinking of trying for a 2-for-1 deal. Basically an open-wall woodshed that happens to have 24 solar panels on the roof. Has anyone else tackled a similar project? Is there a way to mount the panels tight enough that they are waterproof seams, to skip the cost of a roof that will be completely covered? Or do I need to attach a simple metal roof to purlins and then mount the racks?

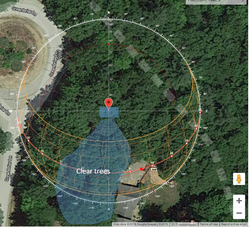

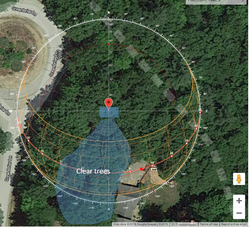

A 13' roof at 40-degree elevation tilt would be 10' high at the peak. Here is a roughly to-scale drawing showing the site. Zoning setbacks are 50' on the front edge, and 30' on the sides and rear edges. This is going to require a lot of tree clearing, which is something we wanted to do anyways for landscaping and aesthetic reasons. Would like to put in some dwarf fruit trees and berry bushes in the newly cleared area. I understand the most critical solar production time is from 10 AM to 2 PM so I will prioritize trees that shade the panels during that time.

It's also going to require some significant site work and trenching. This area is already dedicated to wood processing and storage, so I will have some cleanup and re-arranging to do.

Would like to take advantage of the federal 30% tax credit. Current household usage is ~10,000 kWh/year. PVWatts tells me a nominal 8 kW system pointed due south can generate 10,750 kWh in an average year.

8 kW of 335-W panels is 24 panels. A 6x4 grid would cover 32' by 13'.

After the Great Northeast Deluge of 2018, I realized that I need a wood shed to reliably season firewood in my climate. So I'm thinking of trying for a 2-for-1 deal. Basically an open-wall woodshed that happens to have 24 solar panels on the roof. Has anyone else tackled a similar project? Is there a way to mount the panels tight enough that they are waterproof seams, to skip the cost of a roof that will be completely covered? Or do I need to attach a simple metal roof to purlins and then mount the racks?

A 13' roof at 40-degree elevation tilt would be 10' high at the peak. Here is a roughly to-scale drawing showing the site. Zoning setbacks are 50' on the front edge, and 30' on the sides and rear edges. This is going to require a lot of tree clearing, which is something we wanted to do anyways for landscaping and aesthetic reasons. Would like to put in some dwarf fruit trees and berry bushes in the newly cleared area. I understand the most critical solar production time is from 10 AM to 2 PM so I will prioritize trees that shade the panels during that time.

It's also going to require some significant site work and trenching. This area is already dedicated to wood processing and storage, so I will have some cleanup and re-arranging to do.

Last edited by a moderator:

far easier to sell than an entire building. I would be tempted to install gutters under the seams and use the panels for the roof. Harei is off shoot of the original Parei in Plymouth. Parei seems to have gotten quiet of late, they used to do a lot of solar hot water "barn raisings". I think they got burned somewhat as they were big on evacuated tube solar hot water and I think they like a lot of folks had a lot of defective tubes. One of the founders was a fairly clueless "peak oiler" on the edge of the End Of The World As We Know It crowd, good with PR but not so good with reality.

far easier to sell than an entire building. I would be tempted to install gutters under the seams and use the panels for the roof. Harei is off shoot of the original Parei in Plymouth. Parei seems to have gotten quiet of late, they used to do a lot of solar hot water "barn raisings". I think they got burned somewhat as they were big on evacuated tube solar hot water and I think they like a lot of folks had a lot of defective tubes. One of the founders was a fairly clueless "peak oiler" on the edge of the End Of The World As We Know It crowd, good with PR but not so good with reality.