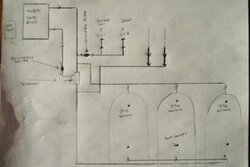

Set up includes a Tarm Solo 60 with 1200 gallons of pressurized storage. Boiler/Storage circ is a 26-99 three speed set on medium. Off of the storage loop is a alpha 15-55 for DHW through a side arm exchanger and a water to air exchanger in the furnace plenum( both run off of zone valves off of the Alpha). The problem is that the alpha is usually pumping to the sidearm on the DHW heater. This is usually at approxiamately 13 gpm. When this is happening I'm not getting any flow through the tanks and the water is coming back to the termovar still hot.. Then the boiler will idle and I have 1200 gallons of water to heat yet. Do I need to do some repiping or can the return from the heat exchangers go back to the middle port on the tank. Then the water going back to the termovar would come directly from the bottom of the tanks? I couldnt figure out why it takes so long to charge the tanks until I just unplugged the Alpha. HOLY COW ,INSTANT TANK HEAT. Go to https://www.hearth.com/econtent/index.php/forums/viewthread/66701/ for plumbing schematic.

HERES THE PROBLEM WITH WATER FLOW ON THE TARM

- Thread starter jimdeq

- Start date

-

Active since 1995, Hearth.com is THE place on the internet for free information and advice about wood stoves, pellet stoves and other energy saving equipment.

We strive to provide opinions, articles, discussions and history related to Hearth Products and in a more general sense, energy issues.

We promote the EFFICIENT, RESPONSIBLE, CLEAN and SAFE use of all fuels, whether renewable or fossil.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Status

- Not open for further replies.

huffdawg

Minister of Fire

Huff, sorry for the misunderstanding the alpha was not plugged. When I said I unplugged I meant I unplugged the power cord. By taking the power from the Alpha was the only way to get decent flow to the tanks. I included a link to my set pictures.

Nofossil

Moderator Emeritus

I don't see a plumbing diagram, but usually sidearms are in series with either the boiler itself or with the most active zone. Sidearms transfer VERY little heat per minute, so there's almost no temperature drop through a sidearm.

NoFossil, I just gated down the flow on a ball valve prior to the sidearm. The alpha is know flowing 3gpm to the sidearm instead of 13gpm. I am hopeing that will naturally make the flow of hot water to the tanks due to the less resistance. I understand what you mean when you say there is very little difference in temps through a sidearm , but it does work. It may not be as fast recharging as other exchangers using another pump. Since December I used only 1% of propane and that was probably due to the sidearm not keeping up. Will limiting the flow through the sidearm drastically reduce the efficiency?

Nofossil

Moderator Emeritus

jimdeq said:NoFossil, I just gated down the flow on a ball valve prior to the sidearm. The alpha is know flowing 3gpm to the sidearm instead of 13gpm. I am hopeing that will naturally make the flow of hot water to the tanks due to the less resistance. I understand what you mean when you say there is very little difference in temps through a sidearm , but it does work. It may not be as fast recharging as other exchangers using another pump. Since December I used only 1% of propane and that was probably due to the sidearm not keeping up. Will limiting the flow through the sidearm drastically reduce the efficiency?

You could reduce the flow through the sidearm to a trickle and it wouldn't make much difference. Since the sidearm has such a low flow rate it's good to put it in series (and upstream) from some other heavily used load so that it gets plenty of 'on' time without running a circulator just for the sidearm.

EricV

Feeling the Heat

I am wondering of the return from the sidearm is taking a different route back to the boiler and bypassing the tank. It seems if he is shutting the flow down tot he sidearm it's forcing it to the tanks instead. Just a thought. A piping diagram would help.

Thanks fellas. I called Tarm and they suggested a Termovar Diverting valve. Is anybody familiar with this valve. I guess it is preset to 160 degrees. Any water returning that is 160 or greater would be diverted back to the heat load or heat exchanger (sidearm). Any thoughts?

ewdudley

Minister of Fire

jimdeq said:Thanks fellas. I called Tarm and they suggested a Termovar Diverting valve. Is anybody familiar with this valve. I guess it is preset to 160 degrees. Any water returning that is 160 or greater would be diverted back to the heat load or heat exchanger (sidearm). Any thoughts?

We're really in the dark here without a schematic. A diverter might be just what you need, but it's all speculation without knowing what's flowing where.

--ewd

Heres the diagram. Sorry for the delay. Just to recap,the water leaves the boiler hot and the alpha is always/usually pumping water to the sidearm. The water then returns to the boiler via Termovar. I am recycling hot water without flow to the tanks. Whats the best fix?

Attachments

ewdudley

Minister of Fire

jimdeq said:Heres the diagram. Sorry for the delay. Just to recap,the water leaves the boiler hot and the alpha is always/usually pumping water to the sidearm. The water then returns to the boiler via Termovar. I am recycling hot water without flow to the tanks. Whats the best fix?

Tarm uses diverting valves in many of their reference designs, and they are a simple and effective alternative to a primary/secondary solution, or a hydraulic separator solution.

A diverting valve is just like a mixing valve used 'in reverse', in fact many mixing valves can be used as diverting valves.

In your situation the system returns (furnace coil and DHW return) would flow into the 'mix' port of the diverting valve. Then according to the setpoint of the diverting valve the water would go one way if it was hot and it would go another way if it was not so hot. Your not-so-hot water would feed to the cold side of your system, same as it does now. The hot side of the diverting valve would be routed back to any of the hot pipes, and from there it would find its way back to the suction side of Alpha and would go round and round until it got cool enough to go back to storage and/or back to the boiler directly.

If you go with a fixed-setpoint diverting valve you have to decide at what temperature the water is hot enough to re-use and get a valve with that setpoint. If you get an adjustable setpoint valve the range of adjustability needs to be suitable for your situation.

A Taco 5000 adjustable mixing valve deployed in a diverting configuration might be adequate, IIRC they're good for 5 or 6 GPM comfortably with a small pump, which would get you 50,000 btu / hour with a 20 degF deltaT on your furnace coil. Might be easier to sweat in and more affordable, but you'd probably need something bigger.

(Be aware that if you do use a mixing valve in a diverting configuration the meaning of 'C' and 'H' is reversed. The hot water is diverted out the 'C' side and the cooler water is diverted out the 'H' side.)

--ewd

Thank you EW, that was the explanation that I needed. I think the diverting valve would help me alot. The only issue I have is getting the pipeing in front of the Alpha. Its gonna take a little bit of remodeling,but thats OK. Today I exprimented with the sidearm, I adjusted the flow and put it to 4GPM. I also adjusted the aquastat that is threaded into the bottom tee of my propane water heater. I set the aquastat at 120degrees. I had it set at 130 before today and it seemed like it never shut off. What I also think was happening was even though the house load was not calling for heat, the alpha was pumping water from the tanks every nite and mixing all the water. Tanks were consistently down to 125 degrees in the morning even without supplying the house. If I can get this all figured out I will be a happy man. Anymore imput? I appreciate all of your help.

- Status

- Not open for further replies.

Similar threads

- Replies

- 8

- Views

- 442

- Replies

- 10

- Views

- 2K

- Replies

- 0

- Views

- 455

- Replies

- 1

- Views

- 2K