HI,

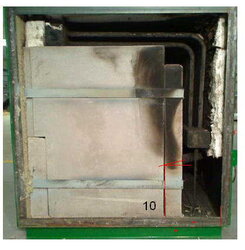

I am starting to build my own boiler. It is similar to a seton, but not based on any one in particular. My question has to do with the combustion air. Is the refactory just a box with the pipes dead heading in the bottom wall or is there some sort of distribution system that goes under the wood or in the bottom refactory. Any thoughts would be helpful or pictures if possible. Thank you

I am starting to build my own boiler. It is similar to a seton, but not based on any one in particular. My question has to do with the combustion air. Is the refactory just a box with the pipes dead heading in the bottom wall or is there some sort of distribution system that goes under the wood or in the bottom refactory. Any thoughts would be helpful or pictures if possible. Thank you