Hi all -

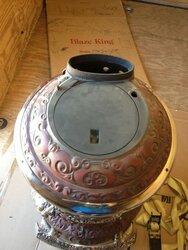

While RV camping in Eagle Nest, NM I made the mistake(?) of falling in love w/ a beautiful antique Round Oak wood stove which now sits in my living room.

I have an existing 6" double-walled chimney and need to find out how to connect my stove to it. It has an oval opening 7 3/4" wide, 3 1/4" deep. The guy I bought it from says I can just "crush" a 6" pipe to fit the oval opening, but this doesn't cut it for me.

I bought an "oval to round" adapter from VentingPipe.com, but the oval end is much too big, and is meant for a Vermont Casting stove.

Any suggestions / solutions???

Thanks in advance.

Bruce

While RV camping in Eagle Nest, NM I made the mistake(?) of falling in love w/ a beautiful antique Round Oak wood stove which now sits in my living room.

I have an existing 6" double-walled chimney and need to find out how to connect my stove to it. It has an oval opening 7 3/4" wide, 3 1/4" deep. The guy I bought it from says I can just "crush" a 6" pipe to fit the oval opening, but this doesn't cut it for me.

I bought an "oval to round" adapter from VentingPipe.com, but the oval end is much too big, and is meant for a Vermont Casting stove.

Any suggestions / solutions???

Thanks in advance.

Bruce