I thought that a new thread may be needed to discuss a bill of materials for a masonry heater.

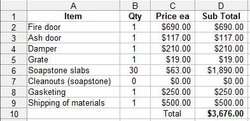

I have started to put together a list below which will need to be filled out to make it complete. For the moment, I am assuming that both the core and facing will be soapstone slabs, 700x300x60mm thick. Smaller pieces could be cut out of these slabs as required. Larger slabs 1000x300x60 are available if it fits the assembly better.

By using soapstone, there is no need for intricate mortar work and the slabs can be fastened together with splines and dowels instead. Grooves to accept the splines and gasketing can be cut in the edges of the slabs with a router equipped with carbide cutters. Holes that must be drilled can be done with a drill press and either carbide drills or a regular drilling machine. Drilling fixtures that have drill bushings welded to a support can be used to place drilled holes in exactly repeatable positions with perfect reliability.

I have yet to see how exactly the pieces are designed to allow for fastening together, but examination of the Finish heaters will reveal how this is done. Every masonry heater needs a min 12" reinforced concrete foundation and most of the soapstone heaters use a 6" or 8" class A stainless steel chimney. The super ultra customized units have the heated benches etc, but I am not considering this level of complexity.

Any contributions or alternative proposals will be appreciated. The first omission that comes to mind is a UL listed chimney connector.

Keith

I have started to put together a list below which will need to be filled out to make it complete. For the moment, I am assuming that both the core and facing will be soapstone slabs, 700x300x60mm thick. Smaller pieces could be cut out of these slabs as required. Larger slabs 1000x300x60 are available if it fits the assembly better.

By using soapstone, there is no need for intricate mortar work and the slabs can be fastened together with splines and dowels instead. Grooves to accept the splines and gasketing can be cut in the edges of the slabs with a router equipped with carbide cutters. Holes that must be drilled can be done with a drill press and either carbide drills or a regular drilling machine. Drilling fixtures that have drill bushings welded to a support can be used to place drilled holes in exactly repeatable positions with perfect reliability.

I have yet to see how exactly the pieces are designed to allow for fastening together, but examination of the Finish heaters will reveal how this is done. Every masonry heater needs a min 12" reinforced concrete foundation and most of the soapstone heaters use a 6" or 8" class A stainless steel chimney. The super ultra customized units have the heated benches etc, but I am not considering this level of complexity.

Any contributions or alternative proposals will be appreciated. The first omission that comes to mind is a UL listed chimney connector.

Keith