Some background

About 12 years ago, I got a "free" boiler. It was a poor install and a friend who was a new homeowner wanted it removed. It had been tied into a 6" wye on an oil furnace flue pipe hooked to an exterior chimney that wasnt high enough. The entire front of the unit was black and the T&P gauge was partially melted. It held pressure so I took a chance. With some help we moved all 1000 pounds of it to my basement where I rewired it and plumbed it into my oil boiler. The boiler is a burnham designed to be a wood or coal unit and rated for 100,000 btu/hr and it had a certification plate. The rotary coal grate was partially melted, so a friend made me a fixed grate out of square stock. All the combustion air goes through the grate so the new grate is as good as new after 11 years. The wood boiler basically heated up the oil boiler and the existing zones worked as they did before. I did install a lockout on the oil burner so that if the wood boiler was up to temp, the oil burner didnt run. The setup worked when there was a high heating demand but once the house heated up, the damper closed and I had a smoke dragon on my hands. Therefore I ran a VC defiant most of the time as it was somewhat controllable on output plus it was in a basement so I could use the basement to temper the air. When I needed the heat, the boiler was a lot better at putting the heat where it was needed and used less wood than heating up the basement. My home office is on the second floor so during the day time I usually would run oil as the load was low and I only needed to heat the office. I also have a hot water maker type hot water tank that is heated by the oil boiler or the wood boiler. I have the tank thermostat on a switch so I usually let it idle until I am running he wood boiler. I have solar hot water that covers me from mid April to October so I dont plan to use the system in summer and I manually cold start the oil boiler if needed.

Finally last year I decided to go with storage. I didnt want to go with a modified and unrated pressurized propane tank for various reasons so I went with 550 gallons of unpressurized storage from American SolarTechnics. I installed the tank myself and as advertised it was an easy install. There are some odd issues with the tank as it is currently configured but the owner is working up a solution once the heating season is over.

The next project was to come up with a control system. The main goal of my system was to run off storage with the oil boiler on cold standby. I only bought one $1000 dollar heat transfer coil so when I was charging up the storage I would revert back to a hot oil boiler using the system basically the way it was. Of great importance was the capability that by flipping one switch, the entire system would default back to oil and that any controls would fail so that the oil boiler worked. I also set it up that if all else fails the system reverts back to oil. I end up on the road for work on occasion and the one thing I didnt want to do was to worry about my house freezing due to the lack of running the wood boiler.

As for controls, I turn the power on, light the fire and flip the three way switch to heat to storage. Once the wood boiler is up to 140 degrees, the system starts circulating to the storage. As long as I feed it wood, it will add to storage until the tank temp maxes out at 195 and then the system bypasses the storage. Just about the same time the tank bypasses, the damper shuts and worse case if the temps still rise, the system dumps to a zone of the house. In absolute worse case the boiler is equipped with a releif valve that sprays water in the combustion chamber. When I am done burning for the night, I flip the three way switch to heat from storage and the system shuts down until a zone calls for heat. At that point the oil boiler gets semi isolated with a fail open valve and the the existing zone pumps push water through the storage tank and then out to the zone distribution header on the outlet of the boiler. If i want to heat up the house quick and skip storage, I always can flip the three way off and run like I used to. The remaining lights are just indicators plus there is a spare switch and a switch for a unit heater zone that is only run off the wood boiler.

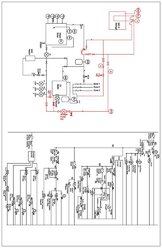

The control panel looks like a bit of an octopus as there are multiple inputs from multiple locations and flex was the easiest way to route the wires. Sure hard conduit would look better but this was a work in progress although someday I may rerun it in PVC. The wiring in the panel is dense and somewhat intimidating. I only had a certain size space so I had to cram it all in. The panel is wired so that every switch, valve and lamp terminates on a Terminal Block. I used a mix of dual plane blocks to save space. Some have internal bus bars between the planes and some do not, plus in spots I used interconnecting bus bars to connect up multiple TB's. Once all the components were terminated I hard wired the logic.

The use of hard wired logic was a definitely a subject of internal and external debate. In industry, i used to encounter many imbedded PLC/controllers supplied with major equipment and frequently after a few years, the capability and documentation to reprogram or diagnose the PLC logic wasnt available. I actually have a complete GE Fanuc system sitting on the shelf that is bascially useless, as I dont have the motivation to track down software and the equipment required to interface with it. Granted hard wiring was a PITA but once in place its not going anywhere and with a appropriate ladder diagram, it isnt that bad to diagnose. Given the local heating techs in northern NH, I realize that if I am not around that the only thing I can do is make sure that to them its a normal oil boiler. I actually have a label on the burner that explains how to disable the system.

The system appears to be working well, my biggest issues are dealing with some prior issues with the heating zones. When I added the office and a hot water maker a friend helped me to get the parts and he went with 1/2 inch instead of 3/4 on two zones. That was fine with oil heated water but with the somewhat lower temps from unpressurized storage it takes a while to heat those zones and given the pressure difference I can get "ghost flow" in my 3/4 inch zone. I expect I will repipe at least one of the zones and possibly add back some radiation in spots.

About 12 years ago, I got a "free" boiler. It was a poor install and a friend who was a new homeowner wanted it removed. It had been tied into a 6" wye on an oil furnace flue pipe hooked to an exterior chimney that wasnt high enough. The entire front of the unit was black and the T&P gauge was partially melted. It held pressure so I took a chance. With some help we moved all 1000 pounds of it to my basement where I rewired it and plumbed it into my oil boiler. The boiler is a burnham designed to be a wood or coal unit and rated for 100,000 btu/hr and it had a certification plate. The rotary coal grate was partially melted, so a friend made me a fixed grate out of square stock. All the combustion air goes through the grate so the new grate is as good as new after 11 years. The wood boiler basically heated up the oil boiler and the existing zones worked as they did before. I did install a lockout on the oil burner so that if the wood boiler was up to temp, the oil burner didnt run. The setup worked when there was a high heating demand but once the house heated up, the damper closed and I had a smoke dragon on my hands. Therefore I ran a VC defiant most of the time as it was somewhat controllable on output plus it was in a basement so I could use the basement to temper the air. When I needed the heat, the boiler was a lot better at putting the heat where it was needed and used less wood than heating up the basement. My home office is on the second floor so during the day time I usually would run oil as the load was low and I only needed to heat the office. I also have a hot water maker type hot water tank that is heated by the oil boiler or the wood boiler. I have the tank thermostat on a switch so I usually let it idle until I am running he wood boiler. I have solar hot water that covers me from mid April to October so I dont plan to use the system in summer and I manually cold start the oil boiler if needed.

Finally last year I decided to go with storage. I didnt want to go with a modified and unrated pressurized propane tank for various reasons so I went with 550 gallons of unpressurized storage from American SolarTechnics. I installed the tank myself and as advertised it was an easy install. There are some odd issues with the tank as it is currently configured but the owner is working up a solution once the heating season is over.

The next project was to come up with a control system. The main goal of my system was to run off storage with the oil boiler on cold standby. I only bought one $1000 dollar heat transfer coil so when I was charging up the storage I would revert back to a hot oil boiler using the system basically the way it was. Of great importance was the capability that by flipping one switch, the entire system would default back to oil and that any controls would fail so that the oil boiler worked. I also set it up that if all else fails the system reverts back to oil. I end up on the road for work on occasion and the one thing I didnt want to do was to worry about my house freezing due to the lack of running the wood boiler.

As for controls, I turn the power on, light the fire and flip the three way switch to heat to storage. Once the wood boiler is up to 140 degrees, the system starts circulating to the storage. As long as I feed it wood, it will add to storage until the tank temp maxes out at 195 and then the system bypasses the storage. Just about the same time the tank bypasses, the damper shuts and worse case if the temps still rise, the system dumps to a zone of the house. In absolute worse case the boiler is equipped with a releif valve that sprays water in the combustion chamber. When I am done burning for the night, I flip the three way switch to heat from storage and the system shuts down until a zone calls for heat. At that point the oil boiler gets semi isolated with a fail open valve and the the existing zone pumps push water through the storage tank and then out to the zone distribution header on the outlet of the boiler. If i want to heat up the house quick and skip storage, I always can flip the three way off and run like I used to. The remaining lights are just indicators plus there is a spare switch and a switch for a unit heater zone that is only run off the wood boiler.

The control panel looks like a bit of an octopus as there are multiple inputs from multiple locations and flex was the easiest way to route the wires. Sure hard conduit would look better but this was a work in progress although someday I may rerun it in PVC. The wiring in the panel is dense and somewhat intimidating. I only had a certain size space so I had to cram it all in. The panel is wired so that every switch, valve and lamp terminates on a Terminal Block. I used a mix of dual plane blocks to save space. Some have internal bus bars between the planes and some do not, plus in spots I used interconnecting bus bars to connect up multiple TB's. Once all the components were terminated I hard wired the logic.

The use of hard wired logic was a definitely a subject of internal and external debate. In industry, i used to encounter many imbedded PLC/controllers supplied with major equipment and frequently after a few years, the capability and documentation to reprogram or diagnose the PLC logic wasnt available. I actually have a complete GE Fanuc system sitting on the shelf that is bascially useless, as I dont have the motivation to track down software and the equipment required to interface with it. Granted hard wiring was a PITA but once in place its not going anywhere and with a appropriate ladder diagram, it isnt that bad to diagnose. Given the local heating techs in northern NH, I realize that if I am not around that the only thing I can do is make sure that to them its a normal oil boiler. I actually have a label on the burner that explains how to disable the system.

The system appears to be working well, my biggest issues are dealing with some prior issues with the heating zones. When I added the office and a hot water maker a friend helped me to get the parts and he went with 1/2 inch instead of 3/4 on two zones. That was fine with oil heated water but with the somewhat lower temps from unpressurized storage it takes a while to heat those zones and given the pressure difference I can get "ghost flow" in my 3/4 inch zone. I expect I will repipe at least one of the zones and possibly add back some radiation in spots.