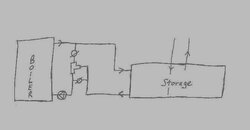

Just trying to get a feel for the best way to run my storage with my Econoburn.

The last couple days it has been low to mid 20's for a high and just below 20 for a night time low.

I have been charging my storage in the evening and ending about 10 pm to about 189 top and 185 bottom.

The next day about 4 pm it is reading 158 top and 140 bottom. I have forced air heat and the air is plenty warm down to 135 with my set up.

The actual boiler temp drops to about 100 to 110 degrees.

So I start the process again. I have not weighed my wood yet but it takes about a shopping cart. I do it gradually with 2 or three small loads.

So what do you find is the best Run it up to a high temp once a day?

or

Is it better to use smaller loads twice a day and not let the boiler and refractory cool down as much?

Any feelings on best way to minimize wood useage?

Does it make a difference?

gg

The last couple days it has been low to mid 20's for a high and just below 20 for a night time low.

I have been charging my storage in the evening and ending about 10 pm to about 189 top and 185 bottom.

The next day about 4 pm it is reading 158 top and 140 bottom. I have forced air heat and the air is plenty warm down to 135 with my set up.

The actual boiler temp drops to about 100 to 110 degrees.

So I start the process again. I have not weighed my wood yet but it takes about a shopping cart. I do it gradually with 2 or three small loads.

So what do you find is the best Run it up to a high temp once a day?

or

Is it better to use smaller loads twice a day and not let the boiler and refractory cool down as much?

Any feelings on best way to minimize wood useage?

Does it make a difference?

gg