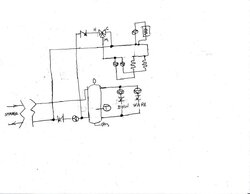

Before I start this project and make a mistake, what do ya think? Boiler loop is 1 1/4" gonna use a loading unit, run of 100' 1" Thermopex to house, total roundtrip approx 250'. Pumps are all 15-58FC's. Storage tank is 850 gallon, buffer/separater is gonna be 60 or 80 gallons. Infloor is in place. Idea is for DHW and WAHX to get the hottest water, (may zone the returns to the buffer to better "reuse" the water). Infloor to always draw the coolest water from the buffer, should never be below the 110 degrees that I use for my infloor. The infloor pumps to replace the coolest water in the buffer with hottest from storage.The only hitch I envision is the Boiler loop return bung is below my loading unit and I'm not sure that thermosiphon will work properly.

Before I start this project and make a mistake, what do ya think? Boiler loop is 1 1/4" gonna use a loading unit, run of 100' 1" Thermopex to house, total roundtrip approx 250'. Pumps are all 15-58FC's. Storage tank is 850 gallon, buffer/separater is gonna be 60 or 80 gallons. Infloor is in place. Idea is for DHW and WAHX to get the hottest water, (may zone the returns to the buffer to better "reuse" the water). Infloor to always draw the coolest water from the buffer, should never be below the 110 degrees that I use for my infloor. The infloor pumps to replace the coolest water in the buffer with hottest from storage.The only hitch I envision is the Boiler loop return bung is below my loading unit and I'm not sure that thermosiphon will work properly.My Design

- Thread starter Armaton

- Start date

-

Active since 1995, Hearth.com is THE place on the internet for free information and advice about wood stoves, pellet stoves and other energy saving equipment.

We strive to provide opinions, articles, discussions and history related to Hearth Products and in a more general sense, energy issues.

We promote the EFFICIENT, RESPONSIBLE, CLEAN and SAFE use of all fuels, whether renewable or fossil.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Status

- Not open for further replies.

stee6043

Minister of Fire

What kind/size of boiler are you looking at? Is your storage inside the house or near the boiler?

If you're running your storage in the house I think you're going to find that 1" thermopex is substantially undersized for many applications.

What's the intent/desire behind your "buffer" tank?

I suspect you're best bet is to control your in-floor temps with a manifold and thermic/mixing valve. You do plan to have controlled mixing for the in-floor, correct?

If you're running your storage in the house I think you're going to find that 1" thermopex is substantially undersized for many applications.

What's the intent/desire behind your "buffer" tank?

I suspect you're best bet is to control your in-floor temps with a manifold and thermic/mixing valve. You do plan to have controlled mixing for the in-floor, correct?

Bob Rohr

Minister of Fire

What kind/size of boiler are you looking at? Is your storage inside the house or near the boiler?

If you're running your storage in the house I think you're going to find that 1" thermopex is substantially undersized for many applications.

What's the intent/desire behind your "buffer" tank?

I suspect you're best bet is to control your in-floor temps with a manifold and thermic/mixing valve. You do plan to have controlled mixing for the in-floor, correct?

Generously size the pipe into the bottom of the large tank. it needs to be able to handle boiler input and system flow. I'd use 2" or at least 1-1/2". Where doese them HW to the radiant mix valve come from? Drawing is a little fuzzy.

hr

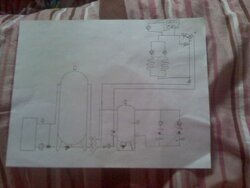

Sorry for the blur, EKO 40, boiler and tank in polebarn four feet apart, hopefully 1 1/4 black pipe big enough for moving the heat to storage . Mixing valve is in top right corner of pic. Buffer tank is to allow water to be reused (go around and round to DHW and WATX) until it has given most of it's heat up, once the water in the buffer gets down to about to 130 degrees at the level of the aquastat, it will kick on the pump sending cooler water from bottom of buffer back to storage. The buffer mixes some, but allows better stratification in storage. HW for infloor comes from bottom of buffer to first tee, the infloor circs draw for themselves then push the expended water back to the mixing valve and to polebarn storage, they should also draw the hottest water from storage to the top of the buffer. The hottest water is always available for the DHW and WATX. The 1" pipe only has to move enough for 35-40kbtuh per heat loss calc. Worked most of this out with Eliot, but he isn't answering emails so figured I'd get some other opinions. Here's Eliots drawing. Have to do the microboiler a touch different but you get the idea.

Bob Rohr

Minister of Fire

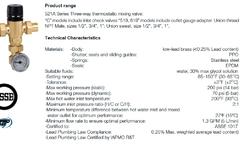

Uppermost, right side zone, why not pump into the load like all the others? Check the spec on the three way mix valve. If this is a 3 way thermostatic valve, you do need some temperature difference between the in "H" and the mixed temperature out to allow the valve to work properly. If the temperature to the "H" is too close to the desired mix the valve may not regulate properly. You may need to supply the mixer with hotter fluid?

hr

Attachments

stee6043

Minister of Fire

Sorry for the blur, EKO 40, boiler and tank in polebarn four feet apart, hopefully 1 1/4 black pipe big enough for moving the heat to storage . Mixing valve is in top right corner of pic. Buffer tank is to allow water to be reused (go around and round to DHW and WATX) until it has given most of it's heat up, once the water in the buffer gets down to about to 130 degrees at the level of the aquastat, it will kick on the pump sending cooler water from bottom of buffer back to storage. The buffer mixes some, but allows better stratification in storage. HW for infloor comes from bottom of buffer to first tee, the infloor circs draw for themselves then push the expended water back to the mixing valve and to polebarn storage, they should also draw the hottest water from storage to the top of the buffer. The hottest water is always available for the DHW and WATX. The 1" pipe only has to move enough for 35-40kbtuh per heat loss calc. Worked most of this out with Eliot, but he isn't answering emails so figured I'd get some other opinions. Here's Eliots drawing. Have to do the microboiler a touch different but you get the idea.

I used 1-1/4" black for my primary loop and it has worked famously for my EKO 40. One tip - simpler is better in many cases with these kinds of systems. Who is Eliot? Hopefully he's installed copious amounts of boilers. If this were my system to design and install I'd ditch the buffer setup altogether and plumb in it such a way as to dramatically reduce the number of pumps you have. Just my two cents, however.

Didn't think about this when Eliot (EWDudley) reccomended it. However, I have read many threads where people say they are utilizing their storage down to 110-120 degrees for their infloor. No mixing valve, or using 80-90 degree water for the infloor maybe? Maybe at the lower temps they are more forgiving? Have to look into.Uppermost, right side zone, why not pump into the load like all the others? Check the spec on the three way mix valve. If this is a 3 way thermostatic valve, you do need some temperature difference between the in "H" and the mixed temperature out to allow the valve to work properly. If the temperature to the "H" is too close to the desired mix the valve may not regulate properly. You may need to supply the mixer with hotter fluid?

hr

My original design that I sent to Eliot to look at was your basic primary secondary. But, he told me, each of my "zones" DHW, WATX, and infloor, return different temp water to storage, causing considerable mixing in the tank. He explained that with this "buffer" set up, the DHW, which requires the hottest water, (but also returns the hottest water to storage), will actually recirculate 2 to 4 times before it gets down to the130 degrees (depending on the starting temp in the buffer) required to kick on the aquastat and start recharging the buffer. Same with the WATX, but probably only twice since its so much bigger and gives a larger delta t. I checked the DHW numbers with the flat plate sizing site, and if I start with 180 degree water it could actually recirculate 3 times (in theory) before it gets down to 130 target. The end result is the hottest water sent back to "main storage" will be less than 130 degrees thereby causing much less mixing. Or at least that was the theory.I used 1-1/4" black for my primary loop and it has worked famously for my EKO 40. One tip - simpler is better in many cases with these kinds of systems. Who is Eliot? Hopefully he's installed copious amounts of boilers. If this were my system to design and install I'd ditch the buffer setup altogether and plumb in it such a way as to dramatically reduce the number of pumps you have. Just my two cents, however.

I would stick with EWD's design on this and I wish mine were set up that way. Some day I may add the buffer tank in my basement. This should allow you to maximize your storage capacity to it's full extent. My primary loop plus 700' of 1 1/2" UG pex (350x2) and a secondary loop in my basement will hopefully work in a similar fashion since I plan to keep it at about ~130 degrees when working off storage(boiler off). I do wonder on your schematic whether the infloor radiant should tap off the lower 1/3 of the buffer tank rather than the bottom. Like Hot Rod mentioned, I would think the hot port would need to be hotter in the 3 way valve. I also wonder why the top right infloor is connected different than the others. You do have some pumps but the 15-58s are about $60, probably less than a zone valve and the lowest setting (60w) should suffice on most of them. A lot easier to justify a keeping spare one of those that can go anywhere.

- Status

- Not open for further replies.

Similar threads

- Replies

- 10

- Views

- 2K

- Replies

- 7

- Views

- 2K

- Replies

- 2

- Views

- 3K

- Replies

- 5

- Views

- 2K