I thought I would do this when it was done, but decided to get it going now. I'll see if I can stumble my way through all the pic posting and try to keep things in order & noted right. Pics are cell phone mostly, so some not the best quality.

I didn't take all the pics I should have. First big thing done was buying & bringing my tanks home. Meant to snap a pic of the pile I picked out of at the scrapyard, but this is the first one I have of them. Brought them home mid-May, wire wheeled & painted them, then took to welder to get fittings welded on. This is after that, patiently awaiting a few welding touch ups:

Lesson: Try to make sure you dont get cast fittings.

Next big event was the day the boiler arrived:

Lesson: Watch the exchange rates. I was doing that but had no choice than to buy when I did. Just happened to be when our dollar was at its lowest point in the past year. Soon as I decided to pull the trigger, down they want like a rock. Now they're back up. Uggh - likely cost me around $500.

Before shot of the boiler area. I should have taken a pic before I cleaned out under & around the steps. It was ugly, 17 years worth of ugly:

Kijiji find - electric boiler for backup & circulator:

First fitting splurge. Turned out to be a drop in the bucket:

Lesson: Multiply fitting estimates by at least 4.

New 80 gallon electric hot water heater:

Lesson: Should have got off the oil long ago. And these things are heavy.

Insulate the stair wall, 1.5" of foam board over 3.5" of fiberglass. Fiberglass was left over from the house build 17 years ago:

Getting into things:

Decided to try one of these mickey mouse crimpers:

They actually don't work too bad once you get the hang of them & the vice grips set right. I'd get real ones though if I was going to be using them anything more than infrequently.

Expansion tank experiment:

Have yet to see how good it will work. Sure as heck is cheaper than real ones.

Got tanks stacked. Man was it hot this day:

And in they go:

Lesson: when you ask your kid to help you, and he says soon as we're done swimming, just go ahead & do it yourself.

New boiler unpacking day:

'Just put that thing on that stand'. Sure sounds easy enough - turned out to be kind of tricky.

But it got up there. And in it goes:

I won't post the lesson there, I'll see if someone spots it. But I can't believe I did that - what a dummy.

Big week this week from skipping out on work a couple hours here and there. Filled the storage tanks with water - not one drip or leak (yes!), except for when I ran them over for just a few seconds. Got the oil tank pumped out (only got two jugs out of it - we were running on fumes) and old boiler all unhooked & up on a pallet & moved out of place, oil line cut & hole in floor patched & floor painted over, chimney swept for I hope the last time ever. Now all ready to go full bore on the assembly & moving the new boiler in place after another trip to supply store:

Lesson: everything associated with this project is heavy. Thank god for levers, shims, dollies & pallet jacks.

That's where I am now - can't wait to get things together and light this puppy. Still have a ton of other things to do after that like insulating & covering the tanks in, then I suppose I should be getting my wood inside before it really starts getting cold. Darned good thing I started this way back in May. Will be more to come...

I didn't take all the pics I should have. First big thing done was buying & bringing my tanks home. Meant to snap a pic of the pile I picked out of at the scrapyard, but this is the first one I have of them. Brought them home mid-May, wire wheeled & painted them, then took to welder to get fittings welded on. This is after that, patiently awaiting a few welding touch ups:

Lesson: Try to make sure you dont get cast fittings.

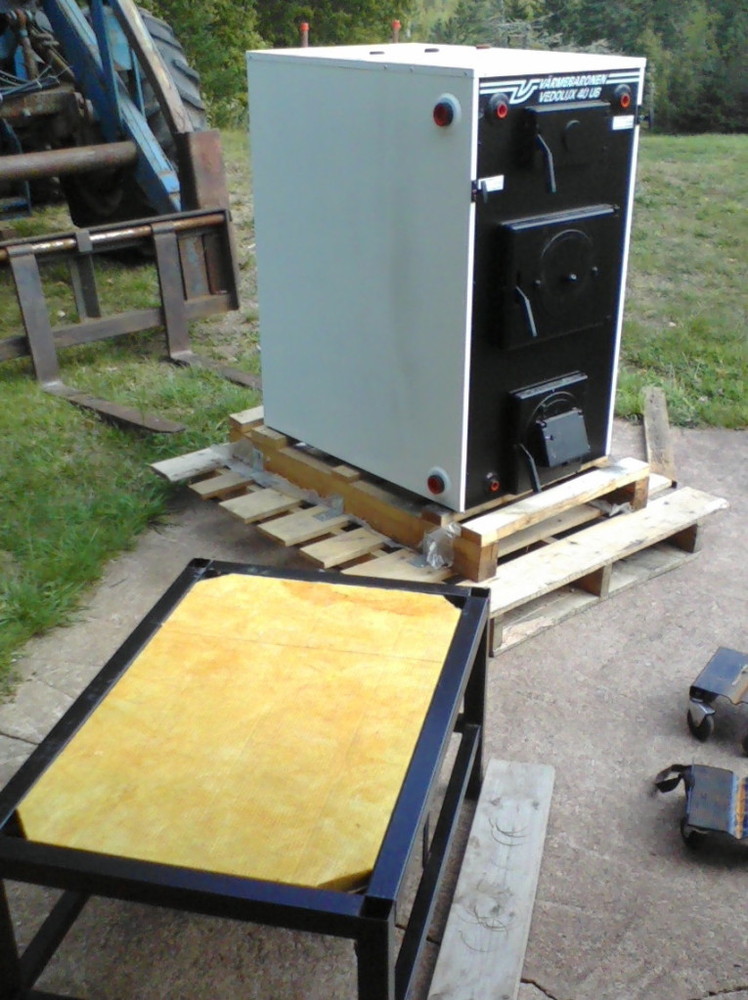

Next big event was the day the boiler arrived:

Lesson: Watch the exchange rates. I was doing that but had no choice than to buy when I did. Just happened to be when our dollar was at its lowest point in the past year. Soon as I decided to pull the trigger, down they want like a rock. Now they're back up. Uggh - likely cost me around $500.

Before shot of the boiler area. I should have taken a pic before I cleaned out under & around the steps. It was ugly, 17 years worth of ugly:

Kijiji find - electric boiler for backup & circulator:

First fitting splurge. Turned out to be a drop in the bucket:

Lesson: Multiply fitting estimates by at least 4.

New 80 gallon electric hot water heater:

Lesson: Should have got off the oil long ago. And these things are heavy.

Insulate the stair wall, 1.5" of foam board over 3.5" of fiberglass. Fiberglass was left over from the house build 17 years ago:

Getting into things:

Decided to try one of these mickey mouse crimpers:

They actually don't work too bad once you get the hang of them & the vice grips set right. I'd get real ones though if I was going to be using them anything more than infrequently.

Expansion tank experiment:

Have yet to see how good it will work. Sure as heck is cheaper than real ones.

Got tanks stacked. Man was it hot this day:

And in they go:

Lesson: when you ask your kid to help you, and he says soon as we're done swimming, just go ahead & do it yourself.

New boiler unpacking day:

'Just put that thing on that stand'. Sure sounds easy enough - turned out to be kind of tricky.

But it got up there. And in it goes:

I won't post the lesson there, I'll see if someone spots it. But I can't believe I did that - what a dummy.

Big week this week from skipping out on work a couple hours here and there. Filled the storage tanks with water - not one drip or leak (yes!), except for when I ran them over for just a few seconds. Got the oil tank pumped out (only got two jugs out of it - we were running on fumes) and old boiler all unhooked & up on a pallet & moved out of place, oil line cut & hole in floor patched & floor painted over, chimney swept for I hope the last time ever. Now all ready to go full bore on the assembly & moving the new boiler in place after another trip to supply store:

Lesson: everything associated with this project is heavy. Thank god for levers, shims, dollies & pallet jacks.

That's where I am now - can't wait to get things together and light this puppy. Still have a ton of other things to do after that like insulating & covering the tanks in, then I suppose I should be getting my wood inside before it really starts getting cold. Darned good thing I started this way back in May. Will be more to come...