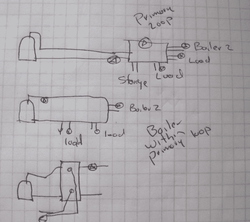

I need help sizing my primary circ pump. The fittings are not set in stone because I am still piecing this together as I go. Since I don't have any experience with hydronic heating I would like to get my pump and thermostatic valve before I start so I can see how things will go together.

Here is what I know so far, hopefully someone can recommend a taco pump that would get me close.

1 1/4 pex = 150' one way from outbuilding to house

a few varies couplers and tees 1 1/2

500 gallon pressurized storage tank

Thanks Mike

Here is what I know so far, hopefully someone can recommend a taco pump that would get me close.

1 1/4 pex = 150' one way from outbuilding to house

a few varies couplers and tees 1 1/2

500 gallon pressurized storage tank

Thanks Mike