Hi Everyone. After about a year of researching and almost nightly logging on at the boiler room, I broke down and bought my EKO 40 and had it delivered in July. Now as the "burning" weather is approaching, I am in panic mode.

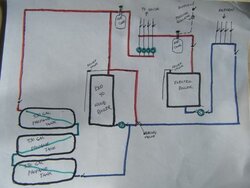

I have a 3700 sq ft home in northern Ohio. I heat with hot water baseboard radiators and an electric boiler. The electric boiler has 4 heat zones but only 1 circ pump and 1 thermostat. In other words, when the house calls for heat it dumps into all four zones equally. I plan on tying in my EKO to all 4 zones but am hoping to control each zone with its own thermostat. I have attached a sketch of my layout, and am hoping someone will please review this and give me their blessing or steer me the correct way. I have already stacked my 3 (330 gal) propane tanks in the basement. and have several hundred dollars of copper piping, valves, and fittings standing by. I recently replaced all of the valves and copper coming out of the elec boiler with new ball valves and copper.

Can someone look over my sketch and tell me what needs to be corrected and added. I am not sure of where to put the circ pump(s) or whether to use zone valves or pumps.

I also do not know where pressure/temp gauges need to be or how many to install.

Where does the aquastat go? Ive seen some attached to EKO yet mine seems to strap directly to the piping.

I have many pics of my tanks etc.

I would appreciate anyone's input. and will have multiple followup questions i'm sure.

I have a 3700 sq ft home in northern Ohio. I heat with hot water baseboard radiators and an electric boiler. The electric boiler has 4 heat zones but only 1 circ pump and 1 thermostat. In other words, when the house calls for heat it dumps into all four zones equally. I plan on tying in my EKO to all 4 zones but am hoping to control each zone with its own thermostat. I have attached a sketch of my layout, and am hoping someone will please review this and give me their blessing or steer me the correct way. I have already stacked my 3 (330 gal) propane tanks in the basement. and have several hundred dollars of copper piping, valves, and fittings standing by. I recently replaced all of the valves and copper coming out of the elec boiler with new ball valves and copper.

Can someone look over my sketch and tell me what needs to be corrected and added. I am not sure of where to put the circ pump(s) or whether to use zone valves or pumps.

I also do not know where pressure/temp gauges need to be or how many to install.

Where does the aquastat go? Ive seen some attached to EKO yet mine seems to strap directly to the piping.

I have many pics of my tanks etc.

I would appreciate anyone's input. and will have multiple followup questions i'm sure.