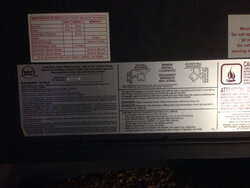

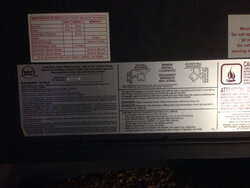

Ok, newbie here when it comes to working on pellet stoves. I'm adding a pellet stove to my woodworking shop to help offset the electric heat and to provide makeup heat for when I have to turn the spray booth fan on. The stove is a Breckwell "The Big E", not sure of age but I downloaded the 2004 manual and it appears older than that.

I don't know if it's seen a lot of use, unfortunately it's seen little maintenance, the fire pot was completely clogged, not a single open hole.

I've been cleaning things and checking systems: fans and auger work, igniter works, control board appears ok.

1. Right now I've completely cleaned inside the hot side of the stove, and have noticed a fair bit of rust on the back wall plate. I'm not rich, but I can make almost anything. Should I make a new back wall, leave it as it is for now, or paint it with a 1500*f ceramic paint? Nowhere does it seem to be burned or rusted through, just looking pretty bad to this untrained eye.

2. On the topic of paint, I want to paint the exterior front, sides, and top of the stove. It's marked up right now and I have a lot of pride in the stuff in my shop. I've repainted our wood stove at home and it turned out great. Anything different about doing the same to a pellet stove?

3. There appears to be this little angled tray that sits loosely on the fire pot. What is this for? Should it be used? This one is starting to rust out but I can make a new one if its an important piece.

4. The igniter tube doesn't line up with the igniter hole in the fire pot. They almost overlap but miss by about 1/8". Should / can I drill a new hole in line with the center of the igniter tube. I have a suspicion that it won't work well unless the two are aligned?

Thank you!

And so the journey into "pellet hood" begins.

I don't know if it's seen a lot of use, unfortunately it's seen little maintenance, the fire pot was completely clogged, not a single open hole.

I've been cleaning things and checking systems: fans and auger work, igniter works, control board appears ok.

1. Right now I've completely cleaned inside the hot side of the stove, and have noticed a fair bit of rust on the back wall plate. I'm not rich, but I can make almost anything. Should I make a new back wall, leave it as it is for now, or paint it with a 1500*f ceramic paint? Nowhere does it seem to be burned or rusted through, just looking pretty bad to this untrained eye.

2. On the topic of paint, I want to paint the exterior front, sides, and top of the stove. It's marked up right now and I have a lot of pride in the stuff in my shop. I've repainted our wood stove at home and it turned out great. Anything different about doing the same to a pellet stove?

3. There appears to be this little angled tray that sits loosely on the fire pot. What is this for? Should it be used? This one is starting to rust out but I can make a new one if its an important piece.

4. The igniter tube doesn't line up with the igniter hole in the fire pot. They almost overlap but miss by about 1/8". Should / can I drill a new hole in line with the center of the igniter tube. I have a suspicion that it won't work well unless the two are aligned?

Thank you!

And so the journey into "pellet hood" begins.