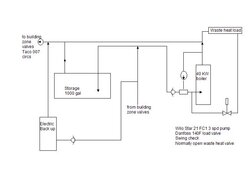

I hope to get this Eko 40 going soon. Will this piping arrangement work? Is there a chance that the load circs will short circuit cold water from the Eko (or the electric heater) when the boiler is off instead of drawing hot water from the storage? The connection tees for the loads and storage are 3 feet vertical above the top of the tank and the Eko. I have only these two connection points for the pressure storage tank.

The piping will be 1.25 inch steel pipe.

Comments welcome, this is a great web site!

The piping will be 1.25 inch steel pipe.

Comments welcome, this is a great web site!