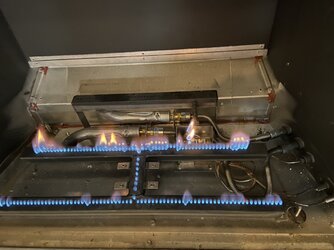

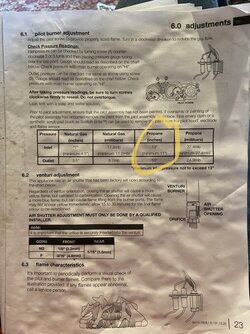

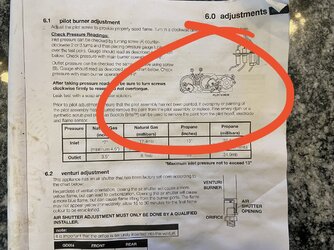

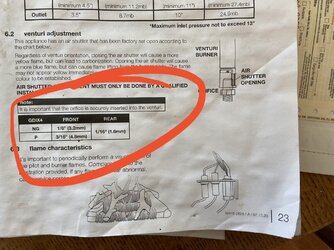

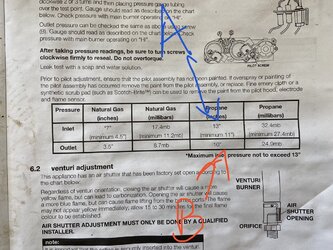

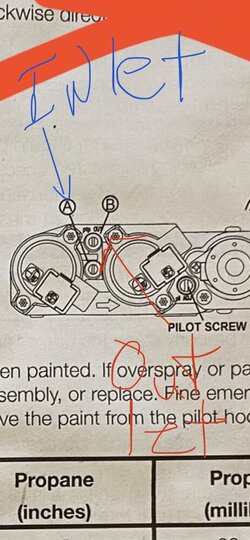

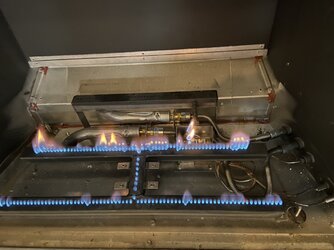

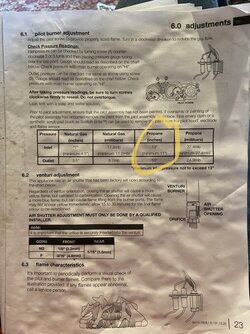

I just purchased this Oakville series GDIX4… and converted it from natural gas to propane… I change the ports to 53 orfice and the stepper motor….

Pilot light works fine… Brand new gas insert ..

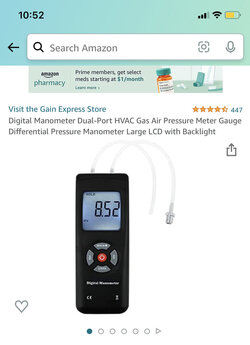

And I’m trying to figure out what is the problem… Everyone’s on service call and won’t be able to come to my place at least for a month and a half… Crazy looking for help or insight

Pilot light works fine… Brand new gas insert ..

And I’m trying to figure out what is the problem… Everyone’s on service call and won’t be able to come to my place at least for a month and a half… Crazy looking for help or insight